Belay Dereje

Email: belay.dereje@wku.edu.et

© 2019 Sift Desk Journals. All Rights Reserved

Belay Dereje

Email: belay.dereje@wku.edu.et

Belay Dereje*1 Solomon Abera2

1Department of Food Process Engineering, Wolkite University

2Department of Food Technology and Process Engineering, Haramaya University

Belay Dereje, Effect of Different Pretreatments and Drying Methods on the Rehydration, Microbial Loads and Sensory Acceptability of Dried Mango (Mangifera Indica L.) Slices(2020)Journal of Food Science & Technology 5(1)

The present study was conducted to assess the effect of various pretreatments and drying methods on the rehydration, microbial loads and sensory acceptability of dried mango slices. Four drying methods (solar, tray, freeze and fluidized bed drying) and four pretreatments (lemon juice, salt solution dips, hot water blanching and control) were considered and arranged in factorial experimental design. The rehydration ratio, microbial loads and sensorial acceptance were evaluated. The result showed that the pretreatments and drying methods showed significant effects on the rehydration ratio, microbial load and sensory acceptance of the dried mango slices. As far as the rehydration ratio was concerned, better rehydration performance was observed for the samples dried by the freeze and fluidized bed driers after subjected to the four different pretreatments. It could be inferred that the total plate count of dried mango slices ranged from 1.4*102-9.6*103 CFU/g while yeast and mould were 4.2*101-8.2*101 CFU/g. Generally, the overall acceptance of dried mango slice was good during three months of storage periods.

Keywords: Mango drying, Microbial loads, Pretreatments, Rehydration

Ethiopia has a rich agro-biodiversity resulting from it's geographical, environmental, ethnic diversity and robust nutritional culture (Wiersinga, 2009). In Ethiopia, it's poor management of post-harvests and lack of low cost and appropriate post-harvest technology losses are extremely high (Wakjira, 2010). Nonetheless, giving more attention would help to reduce the nutritional shortcomings, create jobs, generate revenue and provide industry raw materials and processed forms of export output (Dawit and Asmare, 2008; Shimelis, 2015; Albernaz et al., 2017; Kasso and Bekele, 2018). In addition, there is a shortage and poor post-harvest infrastructure and management in sub-Saharan African countries (Rwubatse et al., 2014). This, in turn, leads to high economic losses (Abano and Sam, 2011; Dessalegn et al., 2016). Therefore, it is important to enhance and promote improved post-harvest management, value-added products and active research programs (Shimelis, 2015; Kumar and Shukla, 2017). Mango is a fleshy stone fruit from the panes Mangifera (Blaise et al., 2009; Shah et al., 2010), tropical fruit of highly seasonal and one of the most popular fruits of the planet (Honja, 2014; Abano, 2015; Girma et al., 2016 ; Sehrawat et al., 2018). It is currently fifth among the key fruit crops worldwide (Shi et al., 2015) and one of the second most likely fruit cultivation grown in Ethiopia (Honja, 2014, Fita, 2014; Lalisa and Daniel, 2017; Neguse et al., 2019). Considering the substantial quantity of mango fruit the processing industry in Ethiopia is incredibly weak (Honja, 2014; Dessalegn et al., 2014; Fita, 2014; Hagos et al., 2019). One way to tackle post-harvest losses is drying (Rwubatse et al, 2014; Omolola et al., 2015; Abe et al., 2018; Farhana et al., 2018; Surendar et al., 2018). Pretreatments are usually done before the fruit is dried so that adverse changes occur during drying and subsequent storage are reduced (Adepoju and Osunde, 2017; Delfiya et al., 2018). Even if drying is attractive technology, in Ethiopia it’s unknown because research and technology are not extensive (Yusufe et al., 2017). Drying of surplus mangoes is a promising preservation technique (Akoy, 2014). However, necessary information on combination of different levels of pretreatments prior to different drying methods and the effect on quality parameters, sensory and microbial quality of dried mango slices in Ethiopia was lacking. Thus, this research was initiated to assess the effect of pretreatments and drying methods on quality parameters of dried mango slices.

Fresh, healthy and disease-free 50 Kilograms of mango fruits of the Keitt cultivar used in this experiment was collected in plastic bags from Asossa, Benishangul Gumuz Regional State, Ethiopia.

2.1. Experimental Plan

The experiment employed a completely randomized design with a factorial arrangement using four pretreatments and four drying methods as indicated in Table 1.

Table1. Experimental layout

|

Drying Methods |

Pretreatments |

|||

|

Lemon juice |

Hot water blanching |

Salt solution |

Control |

|

|

Solar |

SL |

SB |

SS |

SC |

|

Tray |

TL |

TB |

TS |

TC |

|

D3(5 F Freeze |

P FL |

FB |

FS |

FC |

|

Fluidized bed |

T1 D3 FBL |

FBB |

FBS |

FBC |

Where S, T, F and FB represented solar, tray, freeze and fluidized bed of drying methods, respectively and L, B, S and C represented lemon juice, hot water blanching, salt solution dips and control of pretreatments, respectively.

2.2. Sample Preparation

The mangoes were cleaned, peeled and the flesh sliced manually in the direction parallel to their fibres to a thickness of approximately 5 mm with a sharp stainless steel knife (Inox stainless, Brazil) (Lydia Abiola Adepoju & Osunde, 2017). For lemon juice, slices were subjected to pretreatment of equal parts of lemon juice and distilled water mixed solution 0.5 v/v (Abano and Sam-Amoah, 2011; Abano et al., 2013) in container (Op plastics, Ethiopia) ensuring full coverage of the slices and allowed for 10 minutes. One minute hot water blanching was done by subjecting the sliced mangoes at 90 ℃ (Beveridge and Weintraub, 1995; Kidmose and Martens, 1999; Doymaz, 2010; Galoburda et al., 2012; Wang et al., 2018) in a water bath (BM 30, Turkey) ensuring full coverage of the slices by water. For salt solution pretreatment, the samples of sliced mangoes were soaked in the solution prepared by 0.011 g/mL (Abano and Sam-Amoah, 2011; Abano et al., 2013) for 10 minutes in container (Op plastics, Ethiopia) ensuring full coverage of the slices. The pretreated slices have been removed from the solution and spread evenly over a perforated tray, allowing the excess solution to drip for 20 minutes (Nyangena et al., 2019).

2.3. Drying Methods

Solar drying of mango slices was carried out in a solar dryer (YYF-2-7112P1, China). Different sides of the slices were turned to increase drying efficiency on a regular basis. A digital hygrometer (PWT-105, China) was used to measure the temperature and relative humidity at the entrance of the collector and the drying chamber. Tray drying of mango slices was carried out in a computer-controlled tray drying (SBANC, Madrid, Spain) which contains drying chamber with a door with a transparent window (360 x 275 mm approx) and a tray holder for four trays. The drying temperature was maintained at 70°C digitally since a higher temperature may result in a darkening of the samples due to non-enzymatic browning and leading to a loss of quality. A laboratory-scale freeze dryer (Lablyo plus, Germany) was used to dry mango slices and drying was separated into three steps and adjusted automatically before drying starts. The primary drying was with total pressure and the temperature inside the vacuum chamber of 52 pa and –52°C respectively for six hours (Izli et al., 2017). The secondary drying stage was at 10°C for 6 hours at the pressure of 20 Pa (Kaewdam, Varith, Nitatwichit, & Jaturonglumlert, 2013). The final product temperature during the secondary drying was about 38ºC for 7 hours (Marques, Prado, & Freire, 2011). Thermocouple probes were used to control and monitor the product temperature on each tray during drying. A batch type laboratory-scale fluidized bed dryer (TG 200, Germany) was used to dry the prepared mango slices. An air temperature of 50°C and airflow of 1.5 m/s was set digitally (Quintana-Zaragoza et al., 2017).

2.4. Data collection

Rehydration experiments were performed according to Doymaz (2010) with some modifications. In brief, about three grams of the dried products were added to 300 mL distilled water, in a 400 mL beaker. Samples were removed after 10, 20, 35, 60, 120 and 180 minutes, drained and weighed.

2.4.1. Microbial Load Analysis

The microbial qualities of the dried fruits were assessed by using the total number of bacteria, mould and yeast analyses (AOAC, 2005). All the colonies were counted using colony counter (362: ISO 9001: 2008 certified, England).

2.4.2. Sensory Evaluation

Test panel of 30 members selected from senior students of Food Process Engineering and staffs of the Department of Food Process Engineering and Chemical Engineering of Wolkite University was employed. The panellists were asked to evaluate the descriptors, rating each sample on a 7-point hedonic scale. The panellists were oriented on the procedures of tasting the samples and filling in the questionnaires. Dried mango slices were analyzed for colour, flavour, taste, texture, mouthfeel, and overall acceptability on the seven point’s hedonic scale (S. Kumar & Shukla, 2017). The sensory score included: like extremely=7, like moderately= 6, like slightly=5, neither like nor dislike= 4, dislike slightly= 3, dislike moderately=2, dislike extremely=1.

2.5. Statistical Analysis

Statistical analysis was carried out using the software package SAS (SAS Institute, Inc., Cary, North Carolina, USA) by using analysis of variance (ANOVA) for complete randomized design with the factorial arrangement. Fisher’s Least Significance Difference (LSD) test at the significance level 5% (P< 0.05) was used to determine significant differences among samples.

3.1. Effect of Pretreatments and Drying Methods on Rehydration Ratio

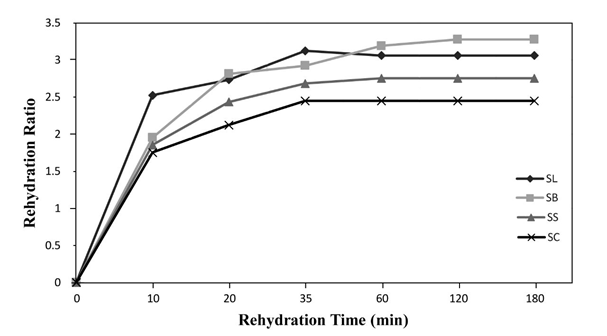

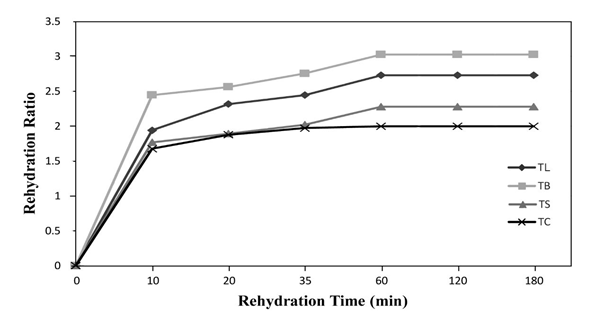

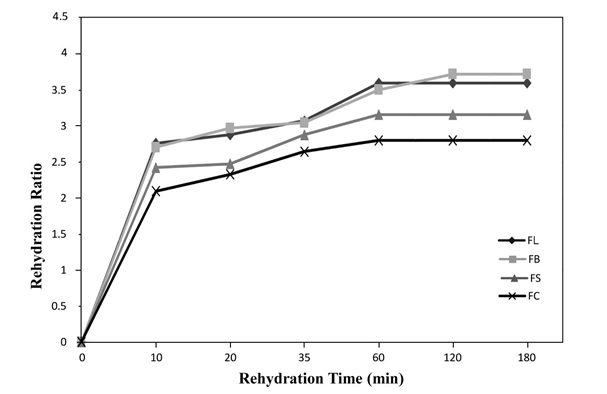

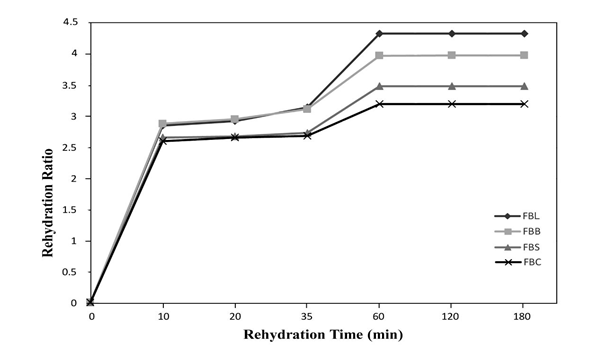

The rehydration curves for each pretreatment through the drying process are shown in Figures 1- 4. As shown in the figures, the dried mango showed high rehydration ratio and after rehydration, the sample mass was increased. Zou et al. (2013), found that the rehydration ratio values of puffed mango chips associated with different osmotic pretreatments ranged from 2.47 to 3.03 and the sample mass was doubled after rehydration. The curves showed significantly high rehydration ratio during the initial period but slowed down slowly to achieve a constant rehydration ratio. In all cases, the ratio is high at the beginning and kept on decreasing until the curve assumes horizontal position. Comparable findings have been reported by Doymaz (2010), Tadesse et al. (2016), Yi et al. (2017) for dried apple, carrot and mango, respectively.

Nevertheless, from the pitches of the curves, at Figures 1, 2, 3 and 4 the rehydration ratio of control samples decelerates faster. The rehydration features depend on the composition of samples, preparation, processing and the degree of chemical-structural disturbances during drying (Nyangena et al., 2019). With the exception of the fluidized bed, dried samples (Figure 4) hot water blanching treatments led to increasing the rehydration ratio values as compared to that other treatments (Figures 1, 2 and 3). Similar results have been reported for apples (Doymaz, 2010) in which they have seen that blanching resulted in the highest rehydration ratio as compared to citric acid and control treatments. Cellular and structural disturbances during blanching may lead to a rehydration ratio increment (Al-amin, Hossain, & Iqbal, 2015).

The result for the freeze-dried samples after subjected to lemon juice was in agreement with Mohamed et al. (2017) who stated samples treated with ascorbic and citric acids had highest rehydration ratio values as compared to control samples. It could be because more rigid and porous structures have been in lemon juice treated and rehydrated water has filled the capillaries to reduce the resistance to deformation and thus encourage swelling and water absorption (E E Abano et al., 2013). In addition, samples pretreated with salt solution had the highest rehydration ratio values as compared to control samples. Similar findings were observed by (Madan & Pare, 2014). According to Lewicki (1998), sodium chloride dissociates crystals, form concentrates spots of sodium and chlorine ions, and ion solvation leads to faster and improved rehydration during rehydration. Furthermore, the rehydration ratio of control samples was shown to be the lowest in all the four drying methods. Maldonado et al. (2010) stated dried fruit without pretreatment presents a lower rehydration ratio. An opposite result was reported in mango chips rehydration treatment by Zou et al. (2013).

The samples dried by fluidized bed dryer after subjected to all of the four pretreatments achieved better rehydration ratio. This result also coherent with other findings of Prakash et al. (2004), who reported the highest rehydration ratio of carrots dried by fluidized bed drying whereas the lowest was that of the solar cabinet dryer. This indicated that the samples retained good texture and absorbed more water (Rajkumar, Kulanthaisami, Raghavan, Gariépy, & Orsat, 2007). According to Prakash et al. (2004) and Madan and Pare (2014), higher rehydration might be due to the faster drying process causes less cellular and structural changes in the final product. Freeze-dried mango samples attained better rehydration ratio as compared to solar and tray dried samples. The result obtained agreed with those of Yi et al. (2017), who observed the highest rehydration ratio of dried mango in the freeze dryer. The possible reason was that the dried samples are formed with better porous structure and higher cell membranes (María et al., 2012; Wang et al., 2018). Similarly, according to Ghiafeh et al. (2007) uniform air drying and better heat transfer, resulting in fewer textural change during drying offered a higher rehydration ratio for the final product. The ability to rehydrate quickly and completely is one of the most important properties of dried mango (Akoy, 2014). Due to the reconstitution of most of the dried products before their final use, the rehydration properties of dried products are used as quality criteria to show physical and chemical changes due to the drying process (E E Abano et al., 2013).

Solar and tray dried samples after those pretreatments had lower rehydration ratio. Driers were likely unable to keep the drying rate constant because air temperature changes and minor shrinkage and case hardening caused less reconstitution of the dehydrated samples (Ghiafeh et al., 2007). Similarly, low rehydration can be caused by factors such as long drying times (Rajkumar et al., 2007), poor product texture caused by poor relative humidity control and airflow fluctuations (Krokida and Maroulis, 2001; Madan and Pare, 2014). The goal of drying the fruit is to make the product stable and easily handled, quickly reconstitute as close as possible to a fresh product (Dame & Sahu, 2016).

The rehydration characteristics can be used as quality indices of a dehydrated product (Xiao et al., 2011; Mishra et al., 2019). Such features reflect the changes occurring during the drying that is influenced by the sample composition, conditions imposed during the drying process and any pretreatments to which the products are subjected (Maskan, 2001). Similarly, according to Maldonado et al. (2010), rehydration loss can involve losses of vitamins, sugars, amino acids, and minerals. In this work rehydration ratio of dehydrated mango slices was affected significantly by the pre-treatments and drying methods. Pretreatments and preparation of the samples before drying, drying itself, lead to changes in the structure and composition of material tissues that change reconstitution properties (Krokida and Maroulis, 2001; Maldonado et al., 2010 and Abano et al., 2013). The results of the present study were in good agreement with report of Zou et al. (2013) 2.47 to 3.03 g/g, Mishra et al. (2019) 2 to 5 g/g and Nyangena et al. (2019) 1.65 to 3.61 g/g for dried mango. But higher than 1.62 to 2.23 g/g that of Abano et al. (2013) for dried mango. The rehydration capacity indicates a degree of damage to foods caused by drying (Tewari, Sehrawat, Nema, & Pal, 2016) and were used as a quality index because they could indicate the physical and chemical changes of samples during drying (Yan et al., 2010; Link et al., 2017; Nyangena et al., 2019). It could affect the sensorial quality of products (Q. Wang et al., 2019).

Figure 1. Rehydration curves of dried mango samples across the four pretreatments in solar drying methods.

Figure 2. Rehydration curves of dried mango samples across the four pretreatments in tray drying methods.

Figure 3. Rehydration curves of dried mango samples across the four pretreatments in freeze-drying methods.

Figure 4. Rehydration curves of dried mango samples across the four pretreatments in fluidized bed drying methods.

3.2. Storage Behaviour of Dried Mango Slices

3.2.1. Microbial load

In order to ensure product safety, microbiological exams such as a total plate count, yeast and mould count were performed and results are given in Table 2. Almost all the products dried by solar and tray driers found microbial loads, but following drying (0th day) counts were relatively low compared to the first, second and third month, where the plates had high-count microbes. According to FAO (1992), plate-counting agar indicates the sanitary conditions for producing and processed food. As indicated in Table 2 freeze and fluidized bed-dried samples after subjected to the four pretreatments offered samples with below detectable level until the second and third month of storage were again the counts were relatively low with a range 1.2*102 to 3.9*102 CFU/g. This guaranteed that the entire product was safe for consumption. Fungi counts were not found in all the products examined until the first month and again not observed for that of freeze and fluidized bed driers with their pretreatments. Yet the sums were fairly low, with the exclusion of the second and third months, where high counts were noticed. The absence of microbes indicates good hygienic and handling practices (Ntuli, Peter, Raphael, Tendekayi, & Jephris, 2017). The solar and tray dried samples had high microbial counts varying from 3.5*101 to 9.6*103 CFU/g and 2.6*101 to 7.5*103 CFU/g observed during the storage periods. In order to reduce the pathogenic prevalence of dried fruits and vegetables strict quality standards must be implemented and enforced (Ntuli et al., 2017). The PCA 3.7*102 and 3.9*102 CFU/g were observed for control samples dried by the fluidized bed and freeze driers.

Regarding potato dextrose agar the highest cells count 5.8*101, 6.3*101 and 8.2*101 CFU/g were observed in control samples dried by solar dryer on the first, second and third month, respectively. The bacterial count in this study was higher than that of reported by Ntuli et al. (2017) but the yeast and mould were lower than their result 1.0 x 103 and 4.2 x 103 CFU/g, respectively for dried mango after the third-month storage. The lowest yeast and mould counts were detected in the freeze and fluidized dried samples with 4.6*101 and 4.9*101 CFU/g. Low moisture content avoids the spoilage by yeast, bacteria, moulds and enzymes (Scanlin, 1997). Adding lemon juice and salt solution as pretreatments combined with low pH for the juice maybe some of the factors that regulate the microbial load at an acceptable level and but also barred any marked proliferation of microbial populations with the sample during the storage. The low pH found during the drying process could thus be one of the factors that contributed to the shelf stability of the dried slices. Mugodo (2017) observed the lowest total aerobic count for the lemon juice treated and the highest was for control mangoes dried. Growth was tiny as far as the permissible limits were alarmed. Throughout the storage period, it was found that there was a very slight increase in the total plate count invariably in all samples. Hence, it could be inferred that drying of the slices with those pretreatments and drying method assured the microbial safety of the product for a storage period of 90 days.

Furthermore, the freeze-dried samples had significantly lower fungi counts compared to the solar, tray and fluidized bed dries samples. Three months of storage time had the highest total bacterial load than the first, second month storage time. The findings have shown the significant effects of pretreatments and drying methods on the microbial quality of the final dried products. The total plate count and yeast and mould count analysis result was found in the safe limit according to FDA recommendations. The recommended value for plate counts and yeast and fungi should not exceed 5*104 and 1.0×103 CFU/g (Witthuhn et al., 2005; FDA, 2012). Therefore, the minimum shelf life was 90 days. Food is a basic need for human survival but it is still a medium for foodborne disease transmission (Yoon and Kim, 2012; Sakagami et al., 2016). The aerobic plate count is intended to estimate the overall number of aerobic organisms in a certain foodstuff (FAO, 1992).

Table 2. Microbial analysis result

|

Sample |

PCA (CFU/g) |

PDA (CFU/g) |

||||||

|

0th day |

30th day |

60th day |

90th day |

0th day |

30th day |

60th day

|

90th day |

|

|

SL |

3.5*101 |

4.5*103 |

5.6*103 |

7.4*103 |

ND |

3.4*101 |

5.5*101 |

6.2*101 |

|

SB |

3.6*101 |

6.5*103 |

7*103 |

7.7*103 |

ND |

3.6*101 |

4.8*101 |

6.4*101 |

|

SS |

3.5*101 |

4.7*103 |

5.2*103 |

6.2*103 |

ND |

3.4*101 |

5.1*101 |

5.5*101 |

|

SC |

5.5*101 |

7.5*103 |

9.2*103 |

9.6*103 |

ND |

5.8*101 |

6.3*101 |

8.2*101 |

|

TL |

2.6*101 |

2.7*103 |

3.6*103 |

4.6*103 |

ND |

3.4*101 |

4.7*101 |

5.3*101 |

|

TB |

2.9*101 |

3.5*103 |

4*103 |

6*103 |

ND |

3.5*101 |

4.4*101 |

5.8*101 |

|

TS |

3.3*101 |

2.5*103 |

3.1*103 |

5.1*103 |

ND |

3.3*101 |

4.5*101 |

5.6*101 |

|

TC |

3.5*101 |

3.6*103 |

4.2*103 |

7.2*103 |

ND |

3.7*101 |

5.2*101 |

6.9*101 |

|

FL |

ND |

102 |

2.2*102 |

2.4*102 |

ND |

ND |

3.6*101 |

4.4*101 |

|

FB |

ND |

102 |

2.3*102 |

2.5*102 |

ND |

ND |

3.8*101 |

4.2*101 |

|

FS |

ND |

102 |

2.5*102 |

2.7*102 |

ND |

ND |

3.3*101 |

4.3*101 |

|

FC |

ND |

102 |

3.5*102 |

3.9*102 |

ND |

ND |

3.2*101 |

4.6*101 |

|

FBL |

ND |

50 |

1.2*102 |

1.4*102 |

ND |

ND |

3.6*101 |

4.5*101 |

|

FBB |

ND |

102 |

2.5*102 |

2.6*102 |

ND |

ND |

3.7*101 |

4.5*101 |

|

FBS |

ND |

70 |

1.2*102 |

2.4*102 |

ND |

ND |

3.4*101 |

4.8*101 |

|

FBC |

ND |

102 |

2.7*102 |

3.7*102 |

ND |

ND |

3.7*101 |

4.9*101 |

Note: SL, SB, SS, SC = Solar drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. TL, TB, TS, TC = Tray drying with juice, hot water blanching, salt solution dip and control sample, respectively. FL, FB, FS, FC = Freeze-drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. FBL, FBB, FBS, FBC = Fluidized bed drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. ND= Not detected, PCA = Plate count agar, PDA= Potato Dextrose agar.

3.2.2. Sensory evaluation

3.2.2.1. Effect of main factors pretreatments and drying methods on sensory acceptability of dried mango

Panellists as shown in Table 3 judged the sensory acceptability of dried products including colour, flavour, taste, texture and overall acceptability of dried mango. On the basis of colour, statistical analysis of the hedonic test showed that the samples dried by fluidized bed scored the highest 6.14 whereas the samples dried by tray dryer scored the lowest 4.88. The mean consumer acceptance scores of colour indicated that lemon juice treated and the control dried mango slices ranged from 5.85 to 5.23 and backed the findings of Masamba et al. (2013), who reported that the lemon juice treated dried mango samples showed better colour acceptance than control samples by the panellists. Both pretreatments and drying methods showed significant differences (P<0.05) on the colour. According to Hwa et al. (2013), the colour of dehydrated fruit is essential for the visual assessment because the first product judgment is colour. Even if the product had of good taste and flavour, off colour of food products is often unacceptable (Gulzar, Ahmed, Qadir, & Imtiaz, 2018). Regarding flavour, taste, and texture acceptability the data did not show significant differences among samples dried by solar and tray driers but statistically were lower than freeze and fluidized bed dried products that showed significant differences among them. With the exception of flavour

where the control samples scored the highest value 5.58, the pretreatments did not show significant difference between them for taste and texture of the dried slices. For the texture, the results are similar to those outlined by Masamba et al. (2013), who reported that there is no significant difference between the control and treated samples of dried mango among the judges. It's one of the main sensory quality attributes affecting food acceptance (Ikoko & Kuri, 2007). It can be seen that the overall score of mango slices dried by the freeze and fluidized bed resulted in the highest score with no significant difference between them. Although mango slices dried by solar and tray driers were not as high as that of freeze and fluidized bed-dried products; these scores were also high to seven points, which means that consumers can accept these mango slices.

For overall acceptability, lower scores were obtained for control samples though when comparisons were made between the four pretreatments, no significant differences while when three samples were compared with the control samples, significant differences were observed. Similar observations made by Abano et al. (2013) and Masamba et al. (2013) who reported that lemon juice pretreatment has an influence on the panellists scoring of flavour, colour and overall acceptability of dried mango.

Table 3. The sensory acceptability of dried mango as affected by pretreatments and drying methods.

|

Drying method |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

Solar |

5.08±0.47c |

5.22± 0.61c |

5.17±0.65c |

5.37±0.66c |

5.73±0.67b |

|

Tray |

4.88±0.45d |

5.09±0.62c |

5.12±0.64c |

5.32±0.67c |

5.58±0.87b |

|

Freeze |

6.01±0.59b |

5.58±0.73b |

5.79±0.74b |

5.70±0.74b |

6.50±0.77a |

|

Fluidized |

6.14±0.57a |

5.96±0.69a |

6.04±0.69a |

5.97±0.66a |

6.29±0.80a |

|

Pretreatment |

|||||

|

Lemon juice |

5.85±0.77a |

5.43±0.80ab |

5.49±0.78a |

5.59±0.72a |

6.28±0.65a |

|

Hot water blanching |

5.58±0.67b |

5.44±0.78ab |

5.52±0.78a |

5.60±0.74a |

6.15±0.77a |

|

Salt solution |

5.46±0.67b |

5.40±0.68b |

5.58±0.73a |

5.60±0.71a |

6.16±0.73a |

|

Control |

5.23±0.79c |

5.58±0.72a |

5.53±0.87a |

5.56±0.76a |

5.57±1.08b |

|

LSD |

0.12 |

0.17 |

0.17 |

0.18 |

0.18 |

|

CV |

8.56 |

12.07 |

12.25 |

12.37 |

12.06 |

Values were means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05).

3.2.2.2. Interaction effect of pretreatments and drying methods on Sensory acceptability of dried mango

Based on colour, statistical analysis of the hedonic test showed that those samples dried with fluidized bed and freeze driers showed significant (P<0.05) differences among them except for few. Taking into account the low ΔE values in these products, which indicated that the colour of groups was more similar to the fresh fruits and preferred by the panellist. The mean score flavour ranged from 4.97 to 6.03 for the sample dried by solar and fluidized bed drying methods with lemon juice and hot water blanching treatments, respectively. On the other hand, the solar-dried samples subjected to lemon juice treatments scored the lowest mean (4.93) for taste while the sample dried by fluidized bed without treatments scored the highest (6.17). It was well known that to market a product successfully in the food industry, the one criteria required is good taste, without this attribute, many products would short-lived in any global market. The fluidized bed with a combination of treatments scored the highest mean for the texture of the dried mango slices. Moreover, the freeze and fluidized bed drying method resulted in the better the sensory quality observed. It can, therefore, be concluded that the driers used significantly affected the sensory quality attributes of the dried samples in different ways. Sensory testing is a way of determining whether the variations between the brand and the differences are perceived and whether one product is more liked than another (Stone, 2018). In general, the overall preference for all the dried samples was above 4.90 indicating that all products were well-liked by the judges (Table 4). Scores from sensory evaluation can reflect consumer preference (Zou et al., 2013).

Table 4. The sensory acceptability of dried mango as affected by the interactions of pretreatments and drying methods

|

Code |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

SL |

5.27±0.45f |

4.97±0.61f |

4.93±0.64fg |

5.33±0.71cd |

5.93±0.37d |

|

SB |

5.17±0.38f |

5.20±0.66def |

5.23±0.63ef |

5.40±0.67bcd |

5.83±0.65d |

|

SS |

5.13±0.43fg |

5.23±0.57def |

5.27±0.58ef |

5.37±0.67cd |

5.90±0.48d |

|

SC |

4.73±0.45hi |

5.47±0.51cd |

5.23±0.73ef |

5.37±0.61cd |

5.27±0.87e |

|

TL |

5.20±0.41f |

5.13±0.63def |

5.30±0.60de |

5.37±0.61cd |

5.80±0.55d |

|

TB |

4.90±0.31gh |

5.07±0.64ef |

5.00±0.53efg |

5.37±0.72cd |

5.83±0.53d |

|

TS |

4.83±0.38hi |

5.10±0.61ef |

5.30±0.60de |

5.37±0.61cd |

5.80±0.66d |

|

TC |

4.60±0.49i |

5.07±0.64ef |

4.87±0.73g |

5.17±0.75d |

4.90±1.18e |

|

FL |

6.40±0.49ab |

5.63±0.76bc |

5.77±0.73bc |

5.67±0.66abc |

6.73±0.52a |

|

FB |

6.03±0.41cd |

5.47±0.68cd |

5.90±0.80abc |

5.73±0.78ab |

6.50±0.82abc |

|

FS |

5.83±0.59de |

5.37±0.61cde |

5.63±0.72cd |

5.67±0.71abc |

6.60±0.62ab |

|

FC |

5.77±0.63e |

5.87±0.78ab |

5.87±0.73abc |

5.73±0.83ab |

6.17±0.95cd |

|

FBL |

6.53±0.51a |

5.97±0.76ab |

5.97±0.72abc |

6.00±0.69a |

6.57±0.55ab |

|

FBB |

6.20±0.41bc |

6.03±0.76a |

5.93±0.69abc |

5.90±0.66a |

6.47±0.78abc |

|

FBS |

6.03±0.41cd |

5.90±0.66ab |

6.10±0.71ab |

6.00±0.69a |

6.33±0.84bc |

|

FBC |

5.80±0.66de |

5.93±0.58ab |

6.17±0.65a |

5.97±0.61a |

5.93±0.83d |

|

LSD |

0.24 |

0.29 |

0.34 |

0.35 |

0.37 |

|

CV |

8.56 |

12.07 |

12.25 |

12.37 |

12.06 |

Values are means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05). Note: SL, SB, SS, SC = Solar drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. TL, TB, TS, TC = Tray drying with juice, hot water blanching, salt solution dip and control sample, respectively. FL, FB, FS, FC = Freeze-drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. FBL, FBB, FBS, FBC = Fluidized bed drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively.

4.4.2.3. Effect of main factors, pretreatments and drying methods, on Sensory acceptability of dried mango stored for a month

The colour scores by the hedonic test indicated that samples dried by solar and tray driers ranged from 4.69 to 4.75 with no significant (P>0.05) difference among them whereas freeze and fluidized bed dried samples ranged from 5.70 to 5.94 with significant (P<0.05) difference between them. Lemon juice treated samples scored the highest value (5.49) and the control scored the lowest value (5.05) with significant differences between the pretreatments. As shown in Table 5, flavour, taste and texture of the samples dried by fluidized bed dryer scored the highest 5.84, 6.02 and 5.97, followed by freeze-dried samples with significant difference between them. This may be due to their aesthetic colour, scent flavour, pleasant taste and blameless texture. In contrast solar and tray, dried samples scored the lowest with no significant difference among them. The overall acceptability of samples dried by solar and tray were 5.64 and 5.52 with no significant difference between them.

Table 5. The sensory acceptability of dried mango as affected by pretreatments and drying methods stored for a month.

|

Drying method |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

Solar |

4.75±0.55c |

5.17±0.58c |

5.14±0.64c |

5.36±0.66c |

5.64±0.67b |

|

Tray |

4.69±0.50c |

5.03±0.57c |

5.07±0.71c |

5.32±0.67c |

5.52±0.86b |

|

Freeze |

5.70±0.60b |

5.53±0.69b |

5.73±0.72b |

5.68±0.72b |

6.40±0.79a |

|

Fluidized |

5.94±0.60a |

5.84±0.66a |

6.02±0.69a |

5.97±0.66a |

6.26±0.85a |

|

Pretreatment |

|||||

|

Lemon juice |

5.49±0.89a |

5.37±0.74a |

5.46±0.78a |

5.58±0.72a |

6.18±0.72a |

|

Hot water blanching |

5.30±0.77b |

5.38±0.72a |

5.48±0.76a |

5.59±0.73a |

6.08±0.78a |

|

Salt solution |

5.24±0.71b |

5.36±0.66a |

5.54±0.71a |

5.58±0.71a |

6.10±0.73a |

|

Control |

5.05±0.73c |

5.47±0.69a |

5.48±0.93a |

5.56±0.76a |

5.47±1.07b |

|

LSD |

0.14 |

0.16 |

0.17 |

0.17 |

0.19 |

|

CV |

10.26 |

11.56 |

12.44 |

12.29 |

12.53 |

Values were means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05).

On the other hand, samples dried by freeze and fluidized bed had 6.40 and 6.26, again with no statistical difference among them. The two data showed significant difference between them. The control samples scored the lowest 5.47 overall acceptability. Even though the overall preference for all the dried samples was reduced from that of previous month (5.58), current it was above (5.52) indicating that all products were well-liked by the judges. The overall acceptance of the new value-added product was evaluated by means of sensory analysis (Kumar and Sagar, 2012; Velickova et al., 2013) such as colour, flavour, taste, visual appearance (Mishra et al., 2019).

3.2.2.4. Interaction effect of pretreatments and drying methods on Sensory attributes of dried mango after a month of the storage period

The actual records of colour score ranged between 4.47 and 6.37 in Table 6. The highest mean score was recorded for samples dried by fluidized bed dryer after being subjected to lemon juice pretreatments and that of the lowest was that of the control samples dried by tray dryer.

Table 6. The sensory acceptability of dried mango as affected by the interactions of pretreatments and drying methods after a first month

|

Code |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

SL |

4.97±0.67d |

4.93±0.58h |

4.90±0.61fg |

5.30±0.70ef |

5.83±0.46cd |

|

SB |

4.63±0.49ef |

5.17±0.65efgh |

5.20±0.61ef |

5.40±0.67cdef |

5.67±0.61d |

|

SS |

4.80±0.48de |

5.20±0.55efgh |

5.23±0.57ef |

5.37±0.67def |

5.83±0.53cd |

|

SC |

4.60±0.50ef |

5.37±0.49def |

5.23±0.73ef |

5.37±0.61def |

5.23±0.86e |

|

TL |

4.83±0.53de |

5.10±0.61fgh |

5.27±0.58de |

5.37±0.61def |

5.73±0.52cd |

|

TB |

4.77±0.43de |

5.00±0.59h |

5.00±0.53efg |

5.37±0.72def |

5.80±0.48cd |

|

TS |

4.70±0.47def |

5.03±0.56gh |

5.23±0.50ef |

5.37±0.61ddef |

5.73±0.58cd |

|

TC |

4.47±0.51f |

4.97±0.56h |

4.77±1.01g |

5.17±0.75f |

4.80±1.21f |

|

FL |

5.80±0.71bc |

5.57±0.73bcd |

5.70±0.75bc |

5.67±0.66abcd |

6.60±0.67a |

|

FB |

5.80±0.55bc |

5.43±0.63cde |

5.80±0.76abc |

5.70±0.75abcd |

6.43±0.86ab |

|

FS |

5.63±0.56c |

5.33±0.61defg |

5.60±0.67cd |

5.60±0.67bcde |

6.50±0.63a |

|

FC |

5.57±0.57c |

5.80±0.71ab |

5.83±0.70abc |

5.73±0.83abc |

6.07±0.91bc |

|

FBL |

6.37±0.61a |

5.87±0.68ab |

5.97±0.72ab |

6.00±0.69a |

6.53±0.73a |

|

FBB |

6.00±0.45b |

5.90±0.71a |

5.90±0.71abc |

5.90±0.66ab |

6.40±0.81ab |

|

FBS |

5.83±0.53bc |

5.87±0.63ab |

6.10±0.71a |

6.00±0.69a |

6.33±0.84ab |

|

FBC |

5.57±0.50c |

5.73±0.64abc |

6.10±0.61a |

5.97±0.61a |

5.77±0.82cd |

|

LSD |

0.24 |

0.32 |

0.35 |

0.17 |

0.19 |

|

CV |

8.56 |

11.56 |

12.44 |

12.29 |

12.53 |

Values are means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05). Note: SL, SB, SS, SC = Solar drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. TL, TB, TS, TC = Tray drying with juice, hot water blanching, salt solution dip and control sample, respectively. FL, FB, FS, FC = Freeze-drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. FBL, FBB, FBS, FBC = Fluidized bed drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively.

Those samples dried by fluidized bed dryer after the hot water blanching scored the highest value 5.90 for flavour. The taste of control samples dried using tray dryer had the lowest value 4.77. The highest acceptability for the texture was observed in samples dried by freeze and fluidized bed driers after all the four treatments. The sensory analysis results showed that the average overall acceptability of the dried mango is highest for all samples of freeze and fluidized bed as compared to solar and tray driers after subjected to different pretreatments. The overall preference for all the dried samples was above (4.80) indicating that all products were well-liked by the judges.

The colour, flavour, taste, texture and overall acceptability ranged between 5.31 to 4.39, 5.70 to 4.91, 5.85 to 4.85, 5.65 to 5.00 and 5.99 to 5.18 for the drying methods. The fluidized bed dried samples had the highest sensory attributes out of seven hedonic points, which were significantly higher than those of the tray and solar dried samples. It was evident from Table 7 that the tray and solar dried mango slices after second-month storage did not show significant differences among the sensory properties in terms of flavour, taste and texture attributes while it was significantly different in terms of the colour and overall acceptability. With the exception of the flavour, where the pretreatments did not show a significant difference between them, but in other sensory attributes the control samples scored the lowest values. When comparisons were made between the lemon juices, hot water blanched and salt solution pretreated samples, no significant differences while when three samples were compared with the control samples, significant differences were observed. Even though the overall preference for all the dried was reduced from that of the first month, up-to-date it was above 5.18 indicating that all products were well-liked by the judges. Sensory assessment is a science that analyzes interventions and interprets people's responses to sensory items (Stone, 2018). According to Velickova et al. (2013), their value, strength and reciprocal relationships are extremely important to brand recognition and consumer acceptance, particularly when a product newly developed is being evaluated.

Table 7. The sensory acceptability of dried mango as affected by pretreatments and drying methods after a second month

|

Drying method |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

Solar |

4.39±0.66c |

5.01±0.69c |

4.99±0.60c |

5.09±0.71c |

5.43±0.73b |

|

Tray |

4.83±0.68b |

4.91±0.52c |

4.85±0.89c |

5.00±0.84c |

5.18±0.76c |

|

Freeze |

4.83±0.68b |

5.38±0.69b |

5.57±0.59b |

5.48±0.65b |

5.94±0.80a |

|

Fluidized |

5.31±0.56a |

5.70±0.59a |

5.85±0.60a |

5.65±0.54a |

5.99±0.57a |

|

Pretreatment |

|||||

|

Lemon juice |

4.82±0.76a |

5.25±0.76a |

5.30±0.73ab |

5.37±0.70a |

5.83±0.81a |

|

Hot water blanching |

4.73±0.81a |

5.28±0.69a |

5.35±0.74ab |

5.33±0.67ab |

5.71±0.81a |

|

Salt solution |

4.68±0.85a |

5.23±0.65a |

5.40±0.64a |

5.33±0.72ab |

5.77±0.67a |

|

Control |

4.49±0.74b |

5.23±0.69a |

5.21±1.01b |

5.19±0.86b |

5.23±0.75b |

|

LSD |

0.17 |

0.16 |

0.17 |

0.17 |

0.17 |

|

CV |

14.21 |

11.88 |

12.53 |

12.92 |

11.96 |

Values were means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05).

The preference rating for the colour of the solar and tray drying methods, they ranged from 4.03 to 4.60 with statistical (P<0.05) difference between them except for very few. On the other hand, those samples dried with freeze and fluidized bed driers ranged between 4.63 and 5.50 are higher group showing significant difference among them (Table 8). Significant (P<0.05) difference was observed between the first and the second groups. The flavour of the samples ranged from 4.73 to 5.80 with statistical (P<0.05) difference among them except for a very few. Actually, the top eight records belonged to samples dried in freeze and fluidized bed driers after the four different pretreatments. The taste of those samples, which had been dried in-tray, was less preferred than solar, freeze and fluidized bed drying methods with their combined pretreatments. Significant (P<0.05) differences were observed on the values of the samples subjected to different treatment combinations. They ranged from 4.33 of those control samples dried in tray to 5.93 of those treated with salt solution and dried in fluidized bed dryers. Actually, the top four records belonged to samples dried in fluidized bed dryers after the four different pretreatments. As shown in Table 8, with the exception of fluidized bed dried samples, the preference rating for the texture of the samples that had been pretreated with hot water blanching and the salt solution was not significantly different from each other in each group. As expected, the fluidized bed and freeze-dried samples had a higher overall acceptances than that of solar and tray dried samples with their pretreatments used.

Table 8. The sensory acceptability of dried mango as affected by the interactions of pretreatments and drying methods after a second month

Values are means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05). Note: SL, SB, SS, SC = Solar drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. TL, TB, TS, TC = Tray drying with juice, hot water blanching, salt solution dip and control sample, respectively. FL, FB, FS, FC = Freeze-drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. FBL, FBB, FBS, FBC = Fluidized bed drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively.

As shown in Table 9, with the exception of the flavour, solar and tray dried mango samples were significantly different (P<0.05) from each other. Similarly, solar and freeze-dried samples were significantly different (P<0.05) from each other except for the overall acceptability.

Table 9. The sensory acceptability of dried mango as affected by the pretreatments and drying methods after a third month

|

Drying method |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

Solar |

4.48±0.73c |

4.68±0.49c |

4.55±0.58c |

4.65±0.59c |

5.18±0.57b |

|

Tray |

3.82±1.10d |

4.69±0.46c |

4.37±0.80d |

4.49±0.59d |

4.56±0.86c |

|

Freeze |

4.93±0.61b |

5.26±0.61b |

5.26±0.57b |

5.08±0.52b |

5.10±0.49b |

|

Fluidized |

5.18±0.55a |

5.54±0.58a |

5.50±0.52a |

5.42±0.51a |

5.68±0.50a |

|

Pretreatment |

|||||

|

Lemon juice |

4.61±0.83ab |

4.98±0.71a |

4.91±0.70ab |

4.88±0.69a |

5.18±0.59a |

|

Hot water blanching |

4.68±0.91a |

5.03±0.67a |

4.98±0.72a |

4.92±0.60a |

5.30±0.63a |

|

Salt solution |

4.68±0.96a |

5.11±0.59a |

5.00±0.74a |

4.94±0.68a |

5.27±0.75a |

|

Control |

4.45±1.01b |

5.04±0.64a |

4.78±0.94b |

4.90±0.68a |

4.77±0.84b |

|

LSD |

0.19 |

0.14 |

0.15 |

0.14 |

0.15 |

|

CV |

16.47 |

10.75 |

12.41 |

11.33 |

11.32 |

Values were means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05).

Samples obtained using the fluidized bed drying methods, received high acceptability scores ranging from 5.18 to 5.68 in all five sensory attributes. On the other hand, there was a significant (P<0.05) differences among the samples subjected to hot water blanching and salt solution and that of lemon juice and control in terms of colour and taste. There was no significant difference between the lemon juices; hot water blanching and salt solution pretreated samples in terms of the overall acceptability but these three were significantly different from control samples. The tray-dried sample had the lowest value of colour, which may be due to its slightly darker colour after the storage. It was observed that loss of colour, flavour, taste, texture and overall acceptability was maximum in the tray-dried samples. The results showed that lower scores for overall acceptability were found in all dried mango samples, which might be related to the sensory attributes losses during storage. In addition, flavour and texture of dried mango samples did not show significant differences among them due to the pretreatments on the third month. Significant differences were found in colour, taste and overall acceptance among samples pretreated with lemon juice, hot water blanching and salt solutions and that of control samples that scored lower values. Generally, the overall acceptance of the samples pretreated with different pretreatments and dried with the four drying methods was good and tended to be liked by the consumers despite the fact that samples were tasted without the addition of any ingredient even though after the third month of storage.

Sensory acceptability evaluation data of the dried samples after 3 months of storage time are shown in Table 10. There was no significant difference between the preference rating of the colour among solar and tray drying methods combined with hot water blanching and salt solution pretreated samples whereas significant difference and high scores were noted among the freeze and fluidized bed drying methods with their combination of the pretreatments. Similarly, samples dried with solar and tray after subjected to the pretreatments had scored the low values for the flavour attributes with no significant difference among them whereas those samples dried with freeze and fluidized bed driers after subjected to all the pretreatments had the highest values with significant (P<0.05) difference between them. The taste score of those samples, which had been dried in-tray, was less than those of solar, freeze and fluidized bed drying methods with their combined pretreatments. The interactions of the pretreatments and drying methods did not show significant differences between each group but there was a significant difference among the solar, tray and freeze, fluidized bed dried samples. As expected, the fluidized bed and freeze-dried samples had the highest overall acceptances than that of solar and tray dried samples with their pretreatments used. All the dried products with the exception of the control tray dried samples, scored at least well.

Furthermore, the sensory analysis showed that the product dried by the fluidized bed dryer subjected to different pretreatments had the highest overall acceptability scores after the month of storage. This could be because the fluidized bed dried samples had the most preferred colour, which was usually one of the first attributes of any food product encountered and has an influence on consumer perception of food by evoking an initial response from the consumer. From data obtained on the sensory evaluation of samples using the hedonic scale used, slices made from mangoes would be accepted when introduced into the market. However, a decrease was observed in sensory attributes of mango slices with the increase in days of storage. This might be due to microbial action on the slices components during storage.

Table 10. The sensory acceptability of dried mango as affected by the interactions of pretreatments and drying methods after a third month

|

Code |

Colour |

Flavour |

Taste |

Texture |

Overall acceptability |

|

SL |

4.40±0.86ef |

4.53±0.57e |

4.40±0.62ef |

4.60±0.62d |

5.27±0.58cd |

|

SB |

4.67±0.55cde |

4.63±0.49de |

4.57±0.50def |

4.70±0.47d |

5.23±0.50cd |

|

SS |

4.50±0.68def |

4.87±0.35d |

4.73±0.52cd |

4.60±0.72d |

5.27±0.58cd |

|

SC |

4.37±0.81ef |

4.67±0.48de |

4.50±0.63def |

4.70±0.53d |

4.93±0.58e |

|

TL |

4.20±0.85fg |

4.67±0.48de |

4.70±0.47cde |

4.53±0.73de |

4.80±0.55ef |

|

TB |

3.87±1.14g |

4.67±0.48de |

4.47±0.68def |

4.47±0.57de |

4.90±0.76ef |

|

TS |

3.83±1.18g |

4.73±0.45de |

4.33±0.66f |

4.67±0.48d |

4.63±0.93f |

|

TC |

3.37±1.10h |

4.70±0.47de |

3.97±1.10g |

4.30±0.53de |

3.90±0.80g |

|

FL |

4.57±0.68def |

5.17±0.65c |

5.00±0.64bc |

5.03±0.56c |

5.03±0.32de |

|

FB |

4.83±0.53bcd |

5.27±0.58bc |

5.33±0.48a |

5.13±0.43bc |

5.30±0.47cd |

|

FS |

5.20±0.55ab |

5.27±0.58bc |

5.40±0.56a |

5.03±0.61c |

5.30±0.47cd |

|

FC |

5.10±0.48ab |

5.33±0.66abc |

5.30±0.53ab |

5.10±0.48bc |

4.77±0.50ef |

|

FBL |

5.27±0.52a |

5.57±0.63a |

5.53±0.51a |

5.33±0.55ab |

5.63±0.56ab |

|

FBB |

5.33±0.61a |

5.57±0.63a |

5.57±0.50a |

5.37±0.49ab |

5.77±0.43a |

|

FBS |

5.17±0.59ab |

5.57±0.57a |

5.53±0.51a |

5.47±0.51a |

5.87±0.35a |

|

FBC |

4.97±0.41abc |

5.47±0.51ab |

5.37±0.56a |

5.50±0.51a |

5.47±0.57bc |

|

LSD |

0.38 |

0.27 |

0.31 |

0.28 |

0.29 |

|

CV |

16.47 |

10.75 |

12.41 |

11.33 |

11.32 |

Values are means ± SD and values in the same column with different superscript letters were significantly different from each other (P<0.05). Note: SL, SB, SS, SC = Solar drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. TL, TB, TS, TC = Tray drying with juice, hot water blanching, salt solution dip and control sample, respectively. FL, FB, FS, FC = Freeze-drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively. FBL, FBB, FBS, FBC = Fluidized bed drying with lemon juice, hot water blanching, salt solution dip and control sample, respectively.

The components of dried food product quality include safety, flavour, texture, colour, healthfulness, and shelf life (Perera, 2014). Statistical analysis of the effect of pretreatments and drying methods on the sensory quality of the dried mango slices showed pretreatments and drying methods, and their interaction had significant effects on sensory quality.

The results of the study showed that dried mango slices had high rehydration performance and low microbial loads with well-liked sensory acceptability. The present study shows that freeze and fluidized bed drying methods produced better-dried mango slices with high quality parameters. It can further be concluded that the pretreatments and drying methods had the potential to extend the shelf life of dried mango slices up to three months. This data was therefore anticipated to effectively cover the existing information gap about drying technologies and could serve as a guide to the participation of additional individuals within the sub-sector if well-used. In conclusion, the right selection of pretreatment during mango slices drying can be used as one of the techniques to control undesirable quality changes.

Firstly, the authors are thankful to Ministry of Education and the Department Food process Engineering and Biology of Wolkite University. The authors also thank Addis Ababa Science and Technology University