Samuel Ayobami Adeyemi

Email: adeyemisamuela@gmail.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 5 ISSUE: 1

Page No: 27-39

Samuel Ayobami Adeyemi

Email: adeyemisamuela@gmail.com

Samuel Ayobami Adeyemi1*, Surajudeen Olarewaju Obayopo1, and Felix Akharume2

1Thermofluid Research Laboratory, Department of Mechanical Engineering, Obafemi Awolowo University, Ile-Ife, Nigeria

2Department of Biosystems and Agricultural Engineering. University of Kentucky Lexington KY 40506

Samuel Ayobami Adeyemi et al. (2020), Evaluation of Intermittent Solar Drying with Seasonal Variation on the Quality of Dried Cocoa Beans Journal of Food Science & Technology 5(1) pp:27-39

Inconsistency in climatic condition and long drying time encountered during drying of cocoa beans may lead to a loss in the quality of the dried beans and consequently lead to a reduction in its market value. The effects of using a mixed-mode solar drying under varying climatic condition of the year on the quality of dried cocoa beans were investigated. Drying was carried out at different climatic conditions: wet-season and dry-season; and the quality characteristics of the dried cocoa beans such as pH, titratable acid content (TA), and free fatty acid (FFA) content were determined for both mixed-mode solar drying and traditional open-air sun drying. Results showed that all the cocoa beans dried under mixed-mode solar drying at a different season of the year reached a safe moisture content (7 to 8 % w.b.) within an average time of 61.5±1.5 hours of intermittent drying.

Additionally, cocoa beans dried during the dry season were more acidic (average TA of 3.3±0.1 meq KOH/g and FFA of 0.4±0.01 mg/g) than those for wet season (average TA of 3.6±0.1 meq KOH/g and FFA of 0.5±0.02 mg/g).

Keywords: Cocoa beans, Drying, Mixed-mode, Quality, Seasonal variation.

Highlights

Cocoa bean is a seed, Theobroma cacao, produced primarily in West Africa (Cote d’Ivoire, Cameroon, Ghana, Nigeria, and Sao Tome), Latin America (Belize, Mexico, Ecuador, Peru, Costa Rica and Brazil), and Indonesia (Sulawesi, Central Sumatra) (Franzen & Mulder, 2007) and used predominantly for the production of chocolate. Cocoa bean is a highly valued commercial export commodity of global interest with a significant economic impact in many of the tropical countries where it’s being produced (Afoakwa et al., 2013). World production of cocoa beans for the year 2017/2018 was estimated to be about 4.6 million tonnes with Africa holding about 73% of the production shares (International Cocoa Organization, 2019; World Cocoa Foundation, 2012). Most of the cocoa bean produced in Africa goes into the export market and as such cocoa beans meant for the export market are grade 1: free of contamination, mold infestation, insect damage, and pesticides residues. The quality of dried cocoa bean ready for export is influenced by prevailing climatic conditions during its post-harvest processing (Afoakwa et al., 2013; Manoj & Manivannan, 2013).

Cocoa beans are produced in humid tropics with annual mean temperature of over 24°C, high relative humidity levels and varied annual rainfall ranges between 1500 and 3000mm. In Africa, where most of the cocoa beans are processed for export, seasonal variations in weather conditions (i.e. unpredictable duration of dry and wet seasons in tropical region) may impact the quality of the dried and the overall production yield. For example, dry weather patterns experience across West Africa in the early part of year 2011/2012 led to a forecast of production shortfalls that year; although, increase in rainfall experienced later in the year and through March 2012, made up for the production deficit (World Cocoa Foundation, 2012). Most African countries experience climatic changes throughout the year, a dry season which last up to four months and a protracted wet season for the rest of the year (Lass, 1985). Other cocoa-producing regions of the world such as India, experience a more pronounced dry season while cocoa producing region in tropical South East Asia and Indonesia experience a more uniform warm and wet climate (Lass, 1985).

Fermentation and drying processing steps are very key to the overall quality of the final dried cocoa bean product (Zahouli et al., 2010). The fermentation process is necessary for improving the flavor and amino-acid profile of the cocoa beans and to break down the mucilaginous pulp surrounding the bean, thereby leading to reduced bitterness and astringency (Adeyeye et al., 2010; Afoakwa et al., 2008; Rodriguez-Campos et al., 2011; Thompson et al., 2013).

Natural drying (such as open-air sun drying and solar dryers) methods, when done properly, have been reported to produce better quality cocoa beans than artificial hot air-drying methods (Bonaparte et al., 1998). The natural drying methods allows slow removal of moisture, continuous fermentation and flavor development leading to a high-quality cocoa bean product; while artificial drying method causes rapid moisture removal, with high content of titratable acid, propionic acid, butyric acid, isobutyric, and isovaleric acids all of which are useful in making a low-quality chocolate (Dina et al., 2015). Jinap and co-authors reported that oven‐dried beans produced from their study contained a high concentration of volatile fatty acid and produced chocolates with a high intensity of off‐flavor (Jinap et al., 1994).

Hybrid solar dryers have been reported to be better than direct and indirect solar dryers in drying cocoa beans. The challenge with direct and indirect solar dryer is that at night time when the sun set, the ambient temperature decreases and the relative humidity increases; so that the cocoa bean in some cases may reabsorb moisture from the environment, leading to a longer drying time and low-quality product (Dina et al., 2015; Fagunwa et al., 2009). A hybrid (or mixed mode) solar dryer circumvents this challenge in that, it has the capacity to store energy during the active drying period and release it at night during resting period to support continuous drying, thereby providing a better quality of cocoa beans (Dina et al., 2015).

However, irrespective of the drying methods or equipment used to process the cocoa bean, the seasonal variation in the climatic conditions (i.e. changing temperature and relative humidity) has been identified as major factors that affect fermentation and drying process and consequently the overall quality of the dried cocoa bean (Afoakwa et al., 2013). High humidity with low drying air temperatures that lead to low drying rate and longer drying time are the conditions experienced by farmers during the protracted period of the wet season, especially in the tropics. As such these conditions affect cocoa production pattern, lead to mold growth, low quality of bean and overall economic loss (Fagunwa et al., 2009). Therefore, objective of this research is to evaluate the effects of seasonal variation in climatic conditions on the quality of dried cocoa beans produced during dry-season and wet-season of a year by adopting two different natural drying methods: mixedmode solar drying and open-air sun drying.

2.1 Sample Preparation

Fresh cocoa pods were obtained from Obafemi Awolowo University Research Farm in Nigeria. The harvested cocoa pods were stored for seven days in a cool dry place at 25˚C average ambient temperature and 72% relative humidity to reduce the possibility of fungal contamination (Afoakwa et al., 2015). The cocoa pods were broken to collect the beans which were then fermented for five days using heap fermentation method (Afoakwa et al., 2015).

2.2 Drying Experiment

2.2.1 Solar dryers

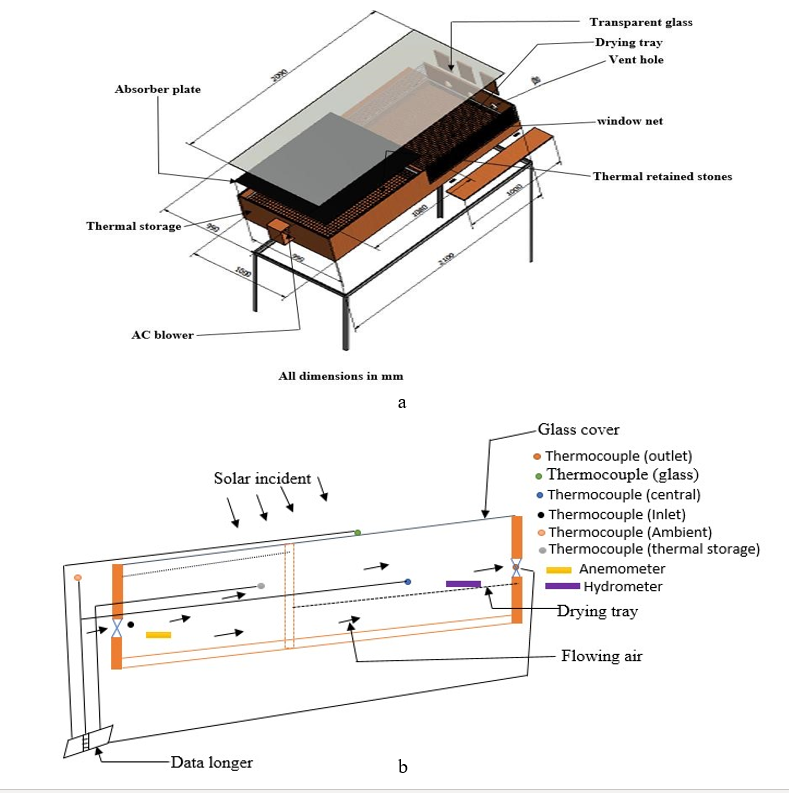

Two different drying systems (mixed-mode solar dryer and traditional open-air) were adopted to dry samples of the fermented cocoa bean during different seasons of the year via dry season and wet-season. The solar dryer used in this experiment was designed (Adeyemi et al., 2019) and simulated in our laboratory using ANSYS software version 14.5. The mixed-mode solar dryer is shown in figure 1a.

2.2.2 Drying period

Solar drying using the mixed-mode dryer and open-air sun-drying systems were carried out during the dry and wet seasons of the year for a total of four different times for each season. The dry season ran for four months, from mid-November to mid-March, so that drying was carried out in a 30-days interval (mid-December, mid-January, mid-February, and mid-March). The wet season ran for eight months, from mid-March to mid-November, so that drying was carried out in a 60-days interval (mid-May, mid-July, mid-September, and mid-November). Both drying methods were used simultaneously on the same day for the same drying conditions (relative humidity, temperature, and airflow). The ambient drying conditions were measured three times for each drying test period and the average reported, and seasonal drying rates of cocoa bean samples for both wet and dry seasons were obtained from the plot of dM/dt.

Figure 1. Experimental setup of the mixed-mode drying system, (a) schematic diagram of the dryer and (b) experimental set-up of the dryer.

2.2.3 Experimental set-up

A CFD designed and simulated mixed-mode solar dryer was used in drying cocoa bean samples as shown in figure 1a. 50 kg of wet-cocoa bean sample was spread in the dryer per each drying batch, and free convection was adopted according to (Fagunwa et al., 2009). For comparison, 50 kg wet-cocoa beans were spread out in a thin layer on a tarpaulin bags to simulate open sun drying method. The Mixed-mode and the open drying methods were simultaneously observed on each drying day for all the experimental runs. Samples were exposed to solar radiation for a period of 9 h (from 9.am to 6 pm) according to natural or sun drying standard exposure time, and the remaining periods of the day were observed as a rest period. (Guehi et al., 2010).

2.3 Drying Parameter Measurement

Drying parameters such as air temperature, relative humidity, and moisture content of the drying beans were measured for each experimental run as shown in figure 1b. Temperature reading obtained for each run was recorded using two types (1 and 5 mm diameter) of J-type thermocouple attached to an Intech Micro Scan 2100-16A data logger (Intech Instruments Ltd) using Microscan 2000 software version 4 connected to a personal computer. Due to longer wet-season (8 months in a year), experimental runs were observed at two months interval during wet-season and at a month interval during dry-season. All the readings were obtained at intervals of three hours during the active drying period in the day and the resting period in the night. The readings were recorded for all the experimental runs in triplicate.

2.4 Quality Assessment Procedures

Quality of the dried cocoa beans was evaluated based on the Free Fatty Acid (FFA) level, titratable acid, pH value, and a grade test. Dried cocoa samples were thoroughly pulverized and sieved through 0.21 mm diameter sieve. The grounded samples were separately placed in sealed polyethylene bags, and they were used for pH, FFA and titratable acid test to determine the effect of season period on quality of dried cocoa beans.

2.4.1 Free fatty acids content

FFA content of the cocoa butter extracted from the samples was determined according to (Afoakwa et al., 2015; Fagunwa et al., 2009; Lasisi, 2014) with modification. One gram of grounded cocoa bean was poured into a 250 ml conical flask. 50 ml of 0.5 M ethanoic potassium hydroxide was added to each of the samples. Heat was applied to dissolve the solution and allowed to cool. Two drops of phenolphthalein indicator were added, and the solution was titrated with 0.5 M HCl until a color change was observed. The percentage FFA was determined as the percentage molar equivalent of the KOH titer to the mass of cocoa beans sample.

2.4.2 pH

The pH for each sample was determined using AOAC (1990) official method 970.21 for cocoa beans. 10g of ground cocoa beans sample was homogenized with 200 ml of hot distilled water. The mixture was filtered through Whatman filter paper No. 4. A 25 ml aliquot was pipetted into a beaker, and the pH of the solution was determined using a pH meter (model MP230 Mettler Toledo MP 230, Mettler Company Limited, Geneva, Switzerland).

2.4.3 Titratable acidity

Titratable acidity was determined according to the method reported in literatures (Guehi et al., 2010; Lasisi, 2014). Forty gram of grounded cocoa beans sample was mixed with de-ionized water in a conical flask. The mixture was distilled and allowed to cool. Phenolphthalein of two drops was used as an indicator. The solution was then titrated against 0.5 M potassium hydroxide (KOH) until the color changed. The titratable acid concentration in the solution was then determined as meq of sodium hydroxide per 1 g of dry nibs.

2.4.4 Grading test

Samples of the dried cocoa beans were taken to cocoa graders for grade test. Three hundred cocoa beans were randomly selected and cut with a knife. Fully fermented (FF) beans, total mold (TM), Slate, damp and other defects (OD) were separated (Malaysian Cocoa Board, 2017). International grading specification test for grading dried cocoa beans was used in grading the dried samples. The Association of Official Analytical Chemists recommends a specification for cocoa grading. For grade I: total mold should not be more than 1 to 12⁄3%, slate (s) 1 to 3%; other defects 1 to 3%. For grade II: total mold between 2 to 3 %, slate 33⁄4 to 4%; other defects 31⁄3 to 4%, while no grade falls below grade II in quality (Association of Official Analytical Chemists, 1990; Malaysian Cocoa Board, 2017). This was used in grading the dried samples.

2.5 Statistical Analysis

All the experimental data were observed in three replicates and average values were reported. One-way analysis of variance (ANOVA) was performed using SPSS software (version 16.0, SPSS Inc., Chicago, IL, USA), and F ratio was used to determine statistical significance at 95 % confidence level (p < 0.05).

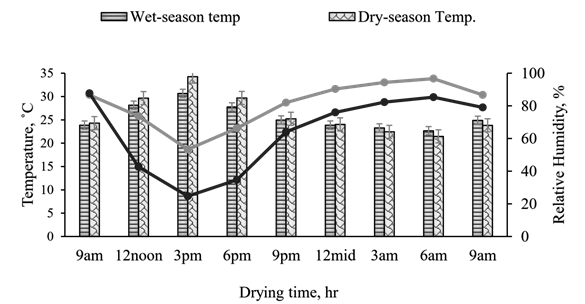

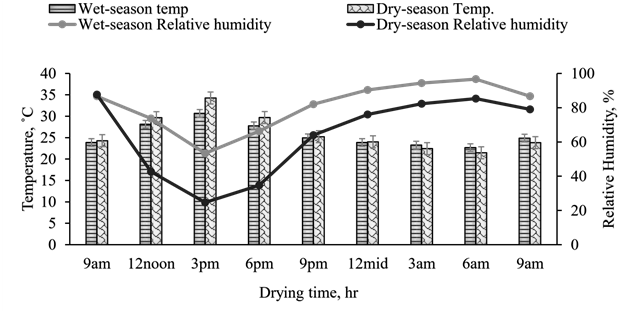

3.1 Effect of Seasonal Variation on Drying Air Quality

Temperature of the drying air was below 35˚C (Fig. 2 and 3) and the quality of drying air observed throughout the year varied from a low to high moist warm air. These were similar to the tropical climatic condition reported in literature (Kricher, 2011). Also, significant low temperature (ranges between 23 to 25 ˚C) was recorded during the night, similar to the reports of other authors (AusAID, 2010 and Fagunwa et al., 2009). Moist air with high relative humidity was observed during the wet season (Fig. 2 and 3). The relative humidity of drying-air during wet-season ranges between 60 to 96%, while relative humidity during dry-season ranges between 20 to 85% were observed.

Figure 2. Condition of the ambient air around the dryers for different seasons of the year. The prevailing ambient temperature and relative humidity of the drying air.

Figure 3. Variation in the conditions of the drying air in the mixed-mode dryer with seasons of the year; the drying air temperature and relative humidity inside the drying chamber.

Also, a lower drying rate and longer drying time were experienced during wet-season of the year (Fig 2 and 3). Similar observations were reported for other agricultural products dried in tropical regions of the world (Kumar et al., 2014).).The relative humidity of the ambient drying air was higher than relative humidity obtained inside dryer irrespective of drying season period (Fig. 2 and 3). While relative humidity of the ambient air near the dryer ranged between 53 to 97% and 24 to 88%, the relative humidity of the drying air inside the dryer ranged between 50 to 88% and 25 to 75% during the wet and dry season respectively (Fig. 2 and 3).

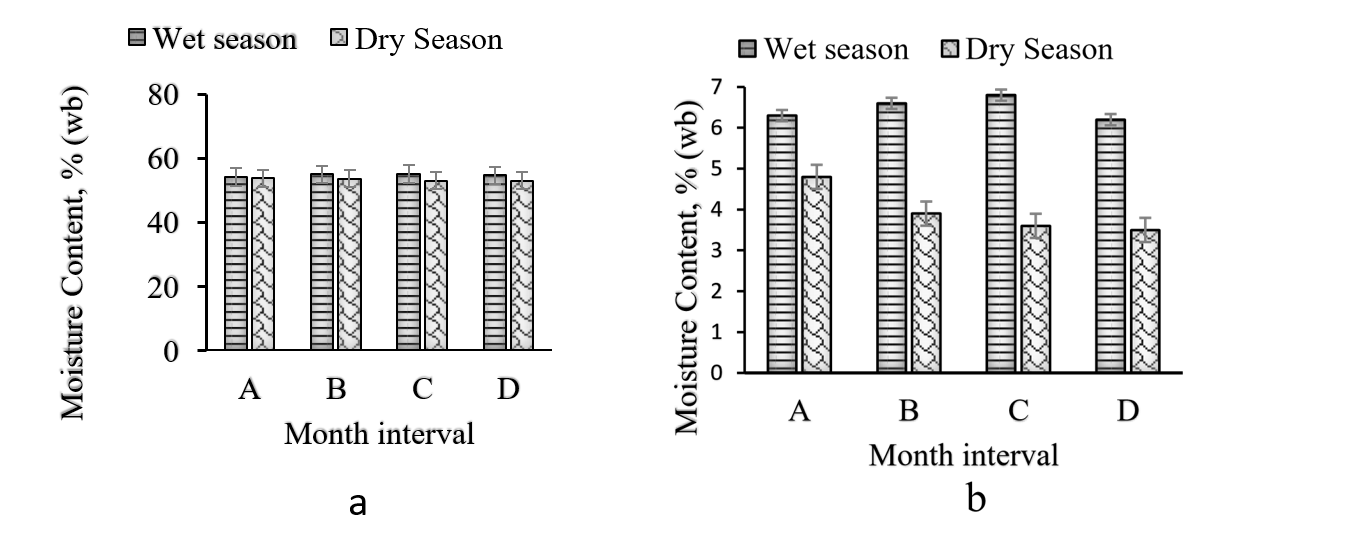

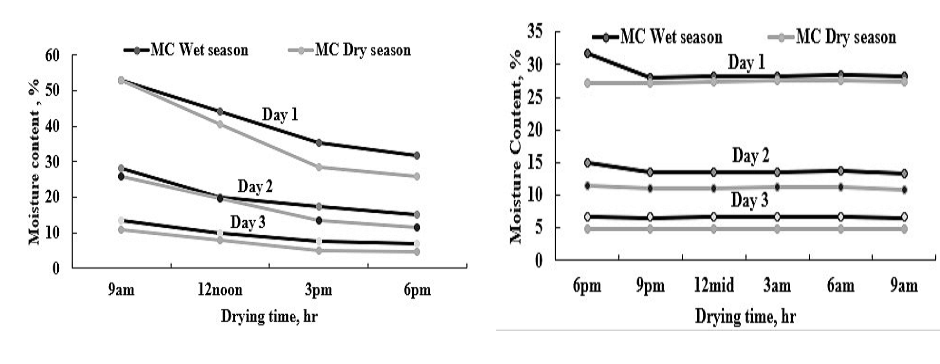

3.2 Seasonal Variation in Moisture Content

There was seasonal variation in moisture content of cocoa bean samples before and after drying (Fig. 4). The initial moisture content before drying was within 54.0 - 54.9% (w.b.) during the wet-season and 52.8 – 53.6 % (w.b.) during dry-season of the year, and equilibrium moisture content reached after drying fell between 3.5 – 4.8% (w.b) during the wet-season and 6.2 - 6.8% (w.b) during dry-season of the year. There was no significant difference between the initial and final moisture content of cocoa beans obtained during the wet and dry season at confidence level (p < 0.05) (Tab. 1).

3.3.1 Moisture desorption

There was variation in drying time require for cocoa beans to reach safe moisture content base on season difference. The moisture desorption kinetics of the drying samples lasted for two and a half days for both season periods: wet-season and dry-season (Fig. 5). It took 60 hours (12:00 noon, day 3) for the beans to reach a safe moisture content (7.9% w.b.) during the dry season and 63 hours (3.00 pm, day 3) to achieve a similar safe moisture content (7.5% w.b.) during wet season. Fagunwa et al., (2009) reported about 72 hours to dry fresh cocoa beans to safe moisture content, and safe moisture of a dried cocoa bean is within the range of 6 to 8 % w.b. (Lasisi, 2014).

Figure 4. Variation in the moisture content of the cocoa bean as affected by the drying season (a) initial moisture content (b) final (equilibrium) moisture content. A-1st drying process, B-2nd drying process, C-3rd drying process and D-4th drying process for both seasons.

There was no significant difference in drying time of cocoa beans due to seasonal difference at confidence level (p < 0.05) (Tab. 1). However, there was a significant difference between samples of cocoa beans dried simultaneously during wet-season using traditional sun drying method at confidence level (p < 0.05) (Tab. 3). Therefore, mixed-mode solar dryer is a promising tool for solving problem of long drying time farmer usually encountered during wet-season of the year. The hybrid solar dryer has been recommended for drying of cocoa beans and other agricultural products in heavy rainfall regions (AusAID, 2010; Fagunwa et al., 2009).

Figure 5. Drying curve showing variation in the instantaneous moisture content of cocoa beans samples as affected by drying seasons during (a) active drying period and (b) resting drying period.

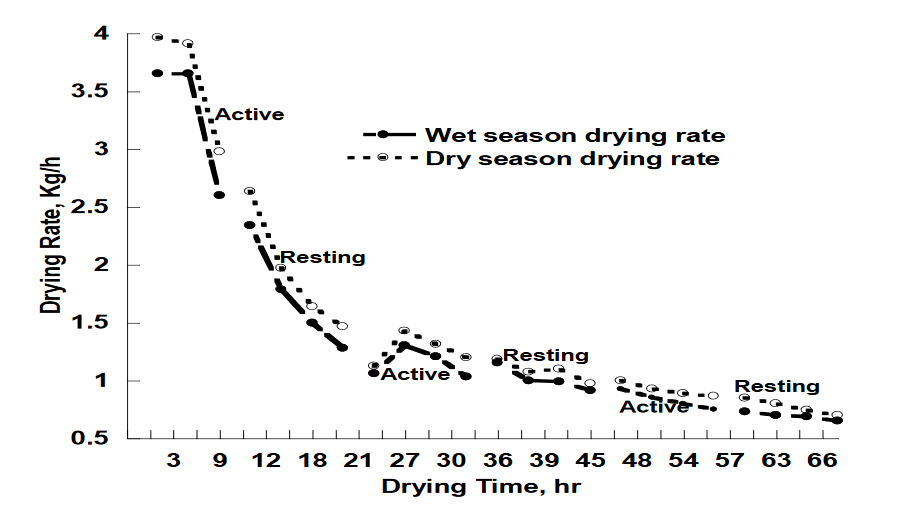

3.3.2 Effects of seasonal variation on drying rate

There was decrease in drying rate with an increase in drying time irrespective of the season of the year (Fig. 6). However, there was a higher drying rate of average difference of 0.03kg/h during the dry season than the wet season. Two distinct drying phases (constant rate phase and falling rate phase) were obtained during the cocoa drying (Fig. 6). Constant drying rate phase lasted for 9 hours during wet-season and 8 hours during dry-season.

Figure 6. Drying rate curve showing variation in drying rate of the cocoa bean as affected by the season of the year

Table 1. Statistical comparison of the drying kinetics for the drying process during the wet and dry season of the year

|

Group |

|

N |

Mean Std. Dev. |

Df |

|

|

Std Dev. Ratio |

F Statistic |

|||

|

Wet-Season Drying process

Dry-Season Drying process

|

Initial MC (wb) Final MC (wb) Drying time (h) Initial MC (wb) Final MC (wb) Drying time (h) |

12 12 12 12 12 12 |

11 11 11 11 11 11 |

|

|

2.16 0.93 1.00 |

|

|

2.82 2.82 2.82 |

||

|

61.50 3.21 6.73 1.71 54.92 1.71 56.25 2.18 4.35 1.77 53.08 1.71 |

|

||||||||||

*N (Sample number), *Df (degree of freedom), *Std. Dev (Standard deviation), *MC (moisture content). Since Std. Dev. Ratio > F statistic at significant level of 0.05, there was no significant difference between initial MC, final MC and drying time obtained during wet and dry season at confidence level 95%.

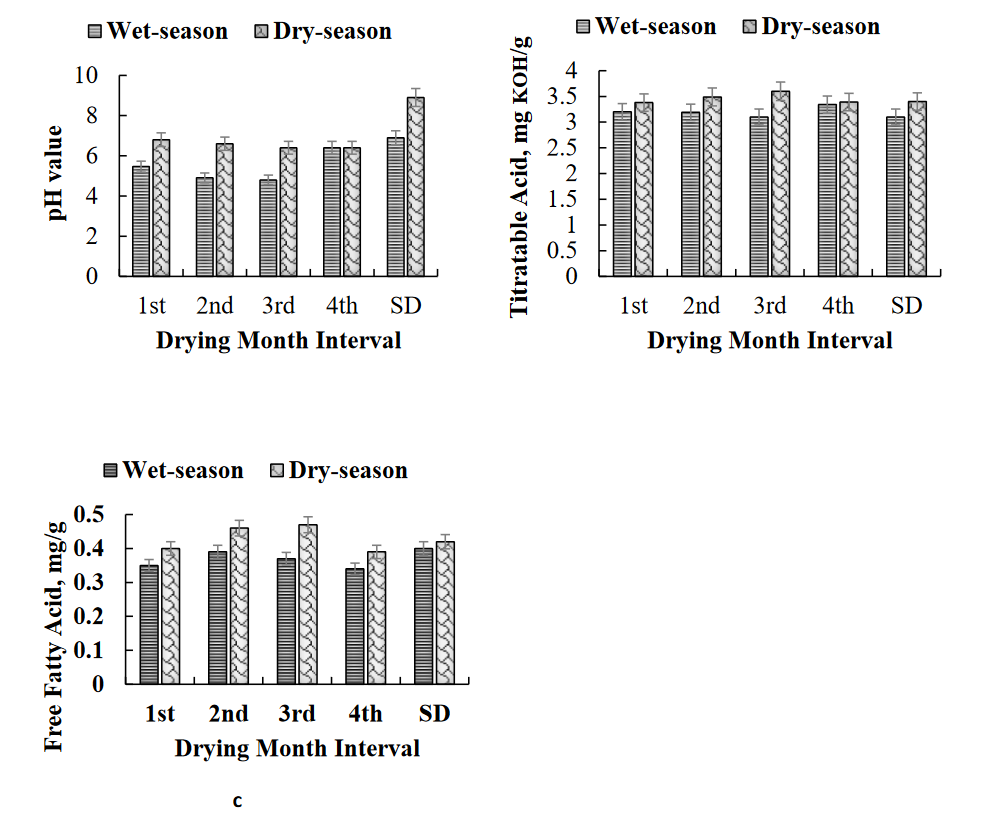

3.4 Comparison of Physio-chemical Properties of Dried Beans

3.4.1 Cocoa quality grading

All the dried beans dried under mixed-mode solar drying were grade 1 irrespective of the season of the year (Table 2). The sample dried under mixed-mode solar dryer had mildly bitter taste without off-flavor irrespective of seasons. The colors of the dried sample were dark reddish brown without infestation of mold, slate or other defects. However, cocoa samples dried using traditional sun-drying method showed significant defects during the wet season of the year.

Defects include infestation of mold, development of off-flavor in the dried beans and slate. These effects were pronounced during the heavy downpour months of June-July and July-August. Cocoa samples dried from March till September using traditional sun-drying method were grade 2 while dried cocoa sample dried during dry season period were grade 1 using same method (Tab. 2). The prevailing climatic conditions starting from June till August had a significant difference (p < 0.05) on the grade of the dried cocoa beans using the method (Table 3). Hence, the quality of dried cocoa obtained using traditional sun-drying method varied during the year.

3.4.2 pH and titratable acidity

There was increase in pH value of cocoa beans dried due to seasonal variation (Fig 7a). While pH-value for cocoa beans dried during wet-season ranges within 6.4 to 8.9, the pH-value for cocoa beans dried during the dry season ranges within 4.9 to 7.1. The increment in pH-value of dried cocoa beans has been reported by other studies. Hii et al., (2006) found that the pH value of dried cocoa beans increases from 4.91 to 5.39 for different increasing loading masses. Takrama and coauthors reported an increase in pH value of dried cocoa from 4.2 to 5.3 owing to different number of drying days (Takrama et al., 2006). Also, there was significant difference in pH value of cocoa samples dried during wet-season and dry-season at confidence level 95% (Tab 3). However, the difference in pH value showed no significant influence on the quality (defected cocoa beans) of dried cocoa beans.

3.4.3 Titratable acid

There was less titratable acid obtained during wet-season, and higher titratable acid was found in cocoa bean samples dried during the middle of dry season (Jan. and Feb.) (Fig. 7b). The level of titratable acid obtained in the dried samples during wet-season falls within the range of 3.19 to 3.38 mg KOH/g, and the level of titratable acid obtained in the corresponding samples dried during dry-season ranges between 3.47 to 3.70 mg KOH/g. There was significant difference in the level of titratable acid found in samples of cocoa beans due to seasonal difference at confidence level 95% (Table 3). However, the variation in titratable acid in the dried beans showed no significant influence on the quality (defected cocoa beans) of the dried beans after grading test.

Table 2. Quality assessment of the dried cocoa beans produced using mixed-mode solar dryer and open-air sun-drying during the dry and wet season

|

Quality |

Dry season monthly experimental runs |

|

Wet season monthly experimental runs |

|||||||

|

parameters |

Dec. |

Jan. |

Feb. |

Mar. |

Sun- drying |

May |

July |

Sept. |

Nov. |

Sun drying |

|

pH |

6.29 ±0.72 |

5.56 ±0.61 |

5.40 ±0.25 |

5.50 ±0.48 |

6.40 ±0.74 |

6.80 ±0.35 |

6.60 ±0.72 |

6.40 ±0.63 |

6.5 ±0.61 |

6.90 ±0.78 |

|

Titratable acid (meq KOH/g) |

3.38 ±0.23 |

3.23 ±0.29 |

3.19 ±0.34 |

3.30 ±0.54 |

3.30 ±0.41 |

3.65 ±0.72 |

3.53 ±0.61 |

3.47 ±0.16 |

3.67 ±0.81 |

3.70 ±0.9 |

|

FFA (mg/g) |

0.40 ±0.02 |

0.42 ±0.03 |

0.43 ±0.01 |

0.41 ±0.03 |

0.39 ±0.04 |

0.42 ±0.10 |

0.46 ±0.04 |

0.47 ±0.08 |

0.49 ±0.01 |

0.40 ±0.05 |

|

Color |

DRB |

DRB |

DRB |

DRB |

DRB |

DRB |

DRB |

DRB |

DRB |

DRB |

|

Taste |

MB |

MB |

MB |

MB |

MB |

MB |

MB |

MB |

MB |

MB |

|

Mold |

None |

None |

None |

None |

1% |

None |

None |

None |

None |

13% |

|

Slate |

None |

None |

None |

None |

1.5% |

None |

None |

None |

None |

16% |

|

Other defects None None None None 0.65% None None None None 6% |

||||||||||

All values are given as mean ± standard deviation *DRB (Dark Reddish Brown), *MB (Mildly Bitter)

Table 3. Statistical comparison of the physiochemical properties of the dried beans dried during dry-season and wet-season.

|

Group |

|

N |

Mean Std. Dev. |

Df |

|

|

Std Dev. Ratio |

F Statistic |

|||||

|

Wet-Season Drying Samples

Dry-Season Drying Samples

|

pH Titratable acid FFA Defected beans pH Titratable acid FFA Defected beans |

12 12 12 12 12 12 12 12 |

11 11 11 11 11 11 11 11 |

|

|

5.5922 |

|

2.82 2.82 2.82 2.82 |

|||||

|

5.69 3.28 0.42 0.33 6.58 3.60 0.42 0.65 |

0.41 0.10 0.05 0.65 0.17 0.05 0.03 0.79 |

|

|||||||||||

|

4.12 3.0 0.67 |

|

||||||||||||

*N (Sample number), *Df (degree of freedom), *Std. Dev (Standard deviation), *Defected beans (dried cocoa samples with quality defects such as mold infestation, slate development, off flavor, foul taste etc.). Since Std. Dev. Ratio < F-Statistic at significant level of 0.05, the samples of cocoa beans dried during wet-season are less acidic than cocoa beans samples dried during dry season of the year.

Table 4. Cut -test details of cocoa sample dried using Traditional sun-drying method.

|

Drying month |

Nos of cocoa beans |

Slate |

Mold infested bean |

Other defects |

|

December |

300 |

3 |

6 |

2 |

|

January |

300 |

4 |

0 |

0 |

|

February |

300 |

8 |

2 |

1 |

|

March |

300 |

3 |

3 |

4 |

|

May |

300 |

73 |

61 |

11 |

|

July |

300 |

98 |

66 |

25 |

|

September |

300 |

19 |

27 |

28 |

|

November |

300 |

12 |

9 |

7 |

*Other defect includes partially fermented, damp, color, taste, odor, etc.

Figure 7. Variation in quality of dried bean sample as affected by the drying seasons. a) pH value, b) titratable acid level, c) free fatty acids content (*SD-Sun drying).

3.4.4 Free fatty acids contents (FFA)

There was variation in FFA level of the dried cocoa beans due to seasonal variation (Fig. 7c). The FFA levels in cocoa beans dried during wet-season varied between 0.35 to 0.4 mg/g, and the FFA levels in cocoa beans dried during dry season ranged between 0.39 to 0.47 mg/g. Cocoa beans dried during wet-season possessed lower FFA content. There was significant difference in

FFA level in dried cocoa bean samples due to seasonal difference at confidence level 95% (Table 3). However, the variation in FFA level had no significant influence on the quality (defected cocoa beans) of the dried beans after grading test.

The drying air condition varies during the year (Fig 2 and 3). The drying air temperature falls below 60˚C, and typically, food materials dried under warm air temperature below 60˚C maintains nutritional value retention (Torres-Moreno et al., 2015). It is known that relative humidity affects moisture removal from drying agricultural products and consequently the drying rate and time (Akharume, 2017; Catalano et al., 2008; Nagaya et al., 2006). During the drying, relative humidity of the ambient air was significantly higher than the dryingair condition inside of the dryer irrespective of the season of the year. The reduction in relative humidity inside dryer is attributed to limitation of mass exchange between dryer and its immediate surrounding due to boundary restriction material of the dryer. Limitation in mass exchange prevents moisture reabsorption and encourages development of chocolate flavor in drying beans especially during the heavy moist laden period of the night (Fagunwa et al., 2009). Low relative humidity inside dryer favors drying rate and reduces drying time. Therefore, a faster drying rate is obtainable within drying system with considerable provision for moisture removal during active drying period, and a tightly closed drying system that sustains heat build-up during resting period.

The discrepancies in the initial moisture content of the cocoa bean samples could be attributed to variation in soil moisture content at different points in a field, and a higher level of initial moisture content during wet season of the year could be attributed to the increase in the field water table during the wet-season of the year (Franzen & Mulder, 2007; Isaac et al., 2007; Mohanty et al., 2000). The final moisture content at which drying terminate is the equilibrium moisture content attained by the drying bean during drying, and the equilibrium moisture content is determined by the point at which there is no longer a significant weight loss in the dried beans.

Intermittent drying curve (Fig. 5) obtained from drying of cocoa bean in the mixed-mode solar dryer followed the typical drying characteristics of other agricultural materials: constant drying rate and falling drying rate (Akharume et al., 2019; Akharume et al., 2016; Hii et al., 2009). However, to evaluate moisture loss kinetics for an intermittent drying of cocoa beans, the drying period was divided into two: active drying period (day) and resting period (night). Moisture loss was rapid during the first 6 hours of the first drying day and continues at a lower rate for the next six hours extending to the resting period while the loss of moistures plateaus for the most part of the resting period. The rapid moisture loss during the first few hours of the first day could be attributed to the presence of free moisture at the surface of fermented beans and ease of interstitial moisture migration at this period of drying (Fagunwa et al., 2009; Hii et al., 2009). This cycle continues for the second and third day of drying until drying reaches equilibrium moisture content.

This intermittent drying process has been reported to influence the development of chocolate flavor (Hii et al., 2009). Under mixed-mode solar drying, longer rapid moisture reduction period observed during the wet season of the year favors the development of chocolate flavor in the dried cocoa beans.

Different drying activities observed during constant drying rate phase and falling drying rate phase. During the constant rate drying phase, free moisture exists at the surface of the drying beans, and the quality of drying air has significant influence on the drying rate. More so, the average drying rate during dry season of the year is higher at this phase with average difference of 0.05 ± 0.01 kg/h (Fig. 6). Fagunwa et al., (2009) attribute the variation in drying rate at this phase to quality of drying air. It was also observed that the period of constant drying rate phase reduces as average quality of drying air improved during the dry season (Fig. 6). The falling rate period is divided into rapid falling drying rate and slower falling drying rate: these two classes reveal difficulties of interstitial moisture migration from the inner interstices of the drying beans to the outer surface of the beans (Fagunwa et al., 2009; Musa, 2012). Hence, drying rate reduces during the falling rate period and the effect of seasonal variation with quality of drying air is limited at this phase owing to the limitation of moisture migration.

Effects of seasonal variations via prevailing climatic drying condition during the dry season and wet-season of a year on the quality of dried cocoa were investigated. Both the Mixedmode solar dryer and open-air sun drying method were used simultaneously during each experimental run. Cocoa bean samples were dried during dry-season and wet-season at month interval, and the results obtained were compared. Cocoa dried during both seasons reached a safe moisture content at an average duration of 61½ hours using mixed-mode solar drying while it took about 2 ½ days to reach equilibrium moisture content using the same drying method. Two drying rate periods were observed for drying of cocoa beans: constant drying rate and falling drying rate period. The quality of cocoa beans dried during both seasons is all grade 1 using mixed-mode solar dryer. However, cocoa beans dried during wet-season are less acidic, and prevailing climatic condition during wet-season of the year hamper quality of cocoa beans dried using traditional sun drying method. A mixed-mode solar dryer is a promising tool for solving problem of inconsistency in weather conditions that usually affect the quality of cocoa beans farmers supply to market in a year.

This work was supported by the Africa Centre of Excellence in ICT-Driven Knowledge Park (OAK-PARK), a World Bank initiative.

Adeyemi, S. A., Obayopo, S. O., & Akharume, F. (2019). Numerical simulation and experimental validation study of a mixed-mode solar dryer for cocoa beans. Journal of Postharvest Technology, 7(3).

Adeyeye, E., Akinyeye, R., Ogunlade, I., Olaofe, O., & Boluwade, J. (2010). Effect of farm and industrial processing on the amino acid profile of cocoa beans. Food Chemistry, 118(2), 357-363.

View ArticleAfoakwa, E. O., Kongor, J., Budu, A., Mensah-Brown, H., & Takrama, J. (2015). Changes in some biochemical qualities during drying of pulp pre-conditioned and fermented cocoa (theobroma cacao) beans. African Journal of Food, Agriculture, Nutrition and Development, 15(1), 9651-9670.

Afoakwa, E. O., Paterson, A., Fowler, M., & Ryan, A. (2008). Flavor formation and character in cocoa and chocolate: A critical review. Critical Reviews in Food Science and Nutrition, 48(9), 840-857. PMid:18788009

View Article PubMed/NCBIAfoakwa, E. O., Quao, J., Takrama, J., Budu, A. S., & Saalia, F. K. (2013). Chemical composition and physical quality characteristics of ghanaian cocoa beans as affected by pulp preconditioning and fermentation. Journal of Food Science and Technology, 50(6), 10971105. PMid:24426021 PMCid:PMC3791243

View Article PubMed/NCBIAkharume, F., Singh, K., & Sivanandan, L. (2019). Effects of liquid smoke infusion on osmotic dehydration kinetics and microstructural characteristics of apple cubes. Journal of Food Engineering, 246, 51-57.

View ArticleAkharume, F. U. (2017). Improving osmo-convective dehydration as a processing technique to food preservation, quality enhancement, and new product development. West Virginia University.

Akharume, F. U., Singh, K., & Sivanandan, L. (2016). Characteristics of apple juice and sugar infused fresh and frozen blueberries. LWT-Food Science and Technology, 73, 448-457.

View ArticleAssociation of Official Analytical Chemists. (1990). Methods of analysis, aoac (Vol. II): The Association.

AusAID. (2010). Cocoa processing methods for the production of high quality cocoa in vietnam.

Bonaparte, A., Alikhani, Z., Madramootoo, C. A., & Raghavan, V. (1998). Some quality characteristics of solar-dried cocoa beans in st lucia. Journal of the Science of Food and Agriculture, 76(4), 553-558. doi:10.1002/(sici)1097 0010(199804)76:4<553::aidjsfa986>3.0.co;2-v 1097-0010(199804)76:4<553::AID-JSFA986>3.0.CO;2-V

View ArticleCatalano, P., Fucci, F., Giametta, F., & La Fianza, G. (2008). A system for food drying using humidity control and low temperature. Agricultural Engineering International: CIGR Journal.

Dand, R. (1997). The international cocoa trade (Vol. 1): John Wiley & Sons.

View ArticleDina, S. F., Ambarita, H., Napitupulu, F. H., & Kawai, H. (2015). Study on effectiveness of continuous solar dryer integrated with desiccant thermal storage for drying cocoa beans. Case Studies in Thermal Engineering, 5, 32-40.

View ArticleEEC. (1973). Directive 73/241/eec by european parliament and the european council relating to cocoa and chocolate products intended for human consumption. Official Journal of the European Communities L 228 of 16/08/1973, 228, 0023-0035.

Fagunwa, A. O., Koya, O. A., & Faborode, M. O. (2009). Development of an intermittent solar dryer for cocoa beans. Agricultural Engineering International: CIGR Journal.

Franzen, M., & Borgerhoff Mulder, M. (2007). Ecological, economic and social perspectives on cocoa production worldwide. Biodiversity and Conservation, 16(13), 3835-3849. doi:10.1007/s10531-007-9183-5

View ArticleGarcía-Alamilla, P., Salgado-Cervantes, M., Barel, M., Berthomieu, G., Rodríguez-Jímenes, G., & García-Alvarado, M. (2007). Moisture, acidity and temperature evolution during cacao drying. Journal of Food Engineering, 79(4), 1159-1165.

View ArticleGuehi, T. S., Zahouli, I. B., Ban‐Koffi, L., Fae, M. A., & Nemlin, J. G. (2010). Performance of different drying methods and their effects on the chemical quality attributes of raw cocoa material. International Journal of Food Science & Technology, 45(8), 1564-1571.

View ArticleHashim, P., Selamat, J., Muhammad, K., & Ali, A. (1999). Effect of drying time, bean depth and temperature on free amino acid, peptide‐n, sugar and pyrazine concentrations of malaysian cocoa beans. Journal of the Science of Food and Agriculture, 79(7), 987-994. 1097-0010(19990515)79:7<987::AID-JSFA314>3.0.CO;2-H

View ArticleHii, C. L., Law, C. L., Cloke, M., & Suzannah, S. (2009). Thin layer drying kinetics of cocoa and dried product quality. Biosystems Engineering, 102(2), 153-161.

View ArticleInternational Cocoa Organization. (2019, March 4, 2019). Quarterly bulletin of cocoa statistic. Retrieved from

View ArticleIsaac, M. E., Timmer, V. R., & Quashie-Sam, S. (2007). Shade tree effects in an 8-year-old cocoa agroforestry system: Biomass and nutrient diagnosis of theobroma cacao by vector analysis. Nutrient cycling in agroecosystems, 78(2), 155-165.

View ArticleJinap, S., Thien, J., & Yap, T. N. (1994). Effect of drying on acidity and volatile fatty acids content of cocoa beans. Journal of the Science of Food and Agriculture, 65(1), 67-75.

View ArticleKricher, J. (2011). Tropical ecology: Princeton University Press.

Kumar, C., Karim, M., & Joardder, M. U. (2014). Intermittent drying of food products: A critical review. Journal of Food Engineering, 121, 48-57.

View ArticleLasisi, D. (2014). A comparative study of effects of drying methods on quality of cocoa beans. IJERT, International Journal of Engineering Research and Technology, 3(1), 991-996.

Lass, R. (1985). Cocoa: Wiley-Blackwell.

Malaysian Cocoa Board. (2017). Specification for grading malaysian cocoa beans. Retrieved from

View ArticleManoj, M., & Manivannan, A. (2013). Simulation of solar dryer utilizing greenhouse effect for cocoa bean drying. International Journal of Advanced Engineering Technology, 4(2), 24.

Mohanty, B., Skaggs, T., & Famiglietti, J. (2000). Analysis and mapping of field‐scale soil moisture variability using high‐resolution, ground‐based data during the southern great plains 1997 (sgp97) hydrology experiment. Water Resources Research, 36(4), 1023-1031.

View ArticleMusa, N. A. (2012). Drying characteristics of cocoa beans using an artificial dryer. Journal of engineering and applied sciences, 7(2), 194-197.

View ArticleNagaya, K., Li, Y., Jin, Z., Fukumuro, M., Ando, Y., & Akaishi, A. (2006). Low-temperature desiccant-based food drying system with airflow and temperature control. Journal of Food Engineering, 75(1), 71-77.

View ArticleRodriguez-Campos, J., Escalona-Buendía, H., Orozco-Avila, I., Lugo-Cervantes, E., & JaramilloFlores, M. E. (2011). Dynamics of volatile and non-volatile compounds in cocoa (theobroma cacao l.) during fermentation and drying processes using principal components analysis. Food Research International, 44(1), 250-258.

View ArticleTakrama, J., Aculey, P., & Aneani, F. (2006). Fermentation of cocoa with placenta: A scientific study. Paper presented at the Proceedings of 15th International Cocoa Research Conference, Costa Rica. vol. II. Proceedings of 15th International Cocoa Research Conference, Costa Rica.

Thompson, S. S., Miller, K. B., Lopez, A. S., & Camu, N. (2013). Cocoa and coffee Food microbiology (pp. 881-899): American Society of Microbiology.

View ArticleTorres-Moreno, M., Torrescasana, E., Salas-Salvadó, J., & Blanch, C. (2015). Nutritional composition and fatty acids profile in cocoa beans and chocolates with different geographical origin and processing conditions. Food Chemistry, 166, 125-132. PMid:25053037

View Article PubMed/NCBIWorld Cocoa Foundation. (2012).

Zahouli, G. I., Guehi, S. T., Fae, A. M., Ban-Koffi, L., & Nemlin, J. G. (2010). Effect of drying methods on the chemical quality traits of cocoa raw material. Advance journal of food science and technology, 2(4), 184-190.