Umar Hassan

Email: uhassan56@yahoo.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 2 ISSUE: 2

Page No: 118-123

Umar Hassan

Email: uhassan56@yahoo.com

Hassan, G.Y Pam, F.O Anafi and S. Umaru

Department of Mechanical Engineering, Ahmadu Bello University, Zaria – Nigeria

Umar Hassan, EXTRACTION AND OPTIMISATION OF OIL FROM BAOBAB (adansonia digitata) SEED KERNEL USING GREY RELATIONAL ANALYSIS(2021)Journal of Chemical Engineering & Bioanalytical Chemistry 2(2)

This study aimed at optimizing the soxhlet extraction process for baobab (adansonia digitata) oil extraction from its seeds kernel. Normal hexane, petroleum ether, and ethanol were considered as the extraction solvents at 60, 65, and 70 oC extraction temperature while retaining the experiment to 80, 100, and 120minutes. In each case, the effect of the three extraction parameters on the performance characteristics was established to achieve the maximum percentage oil yield and minimum percentage free fatty acid. The optimum extraction conditions were attained using grey relational analysis (GRA) of Taguchi’s method after 120 min with n-hexane at 70 oC. The optimized performance parameters are 25.34% oil yield and 2.086% free fatty acid. The study on the effect of each extraction parameters showed that the solvent type has the highest level of influence of 55% followed by extraction time 36% and the extraction temperature of 9%. The results also showed that the method could be used for mass extraction and onward biodiesel production.

Keywords: grey relational analysis, optimization, soxhlet extraction, and baobab

Oil extraction has been one of the major and most important steps for understanding the viability of any vegetable based feedstock for biofuels, foods, cosmetics, and medicinal purposes. This is because it determines the quality and quantity of the oil extracted (Divine and Anuanwen, 2020). There are several oil-bearing plants with thousands of sub-species that could be used to grow and obtain oil-bearing seeds (Salvi and Panwar, 2012). Although vegetable-based feedstock is of different categories in-terms of oil content, edibility, and sustainability, the oils from such sources are potentially inexhaustible and could serve as an alternative to liquid fuels (Hasan et al, 2013). To effectively sustain vegetable oil to replace liquid fuels despite the increasing demand for fuel on daily basis, a high-performance technique of separating the oil content from its kernel for optimum yield is essential. According to Saidat et.al, (2016), those techniques are categorized into mechanical extraction (mechanical press), supercritical fluid, and solvent extraction methods. The main emphasis of comparatively selecting any of those oil extraction methods is explicitly converged to either obtaining a feasible oil yield of sufficient quantity, clear and uncontaminated oil after extraction, and/or qualitative oil residue for higher economic value of the extraction process (Mälina et. al, 2014). Each of these methods suffers one or more drawbacks which may be a motive behind selecting one method over another.

Maria et al. (2008) reported that the mechanical extraction process is the most widely used method; however, the extracted oil contained a significant amount of water and metals. While using supercritical fluid, very high purity of the extracted oil is ascertained; but associated with higher operating and investment costs. They, therefore, suggested solvent extraction which gives higher yield and less turbid oil than mechanical extraction, and relatively low operating cost when compared with supercritical fluid extraction.

Reports revealed that solvent (Soxhlet extraction) has been the most commonly employed technique used to extract and recover oil from seeds, nuts, and any other natural products. In the method, non-polar solvents most especially hexane have been the most widely used as oil extraction solvent (Naimah et al., 2014). Researchers are still putting more emphasis on finding out more ways to improve those extraction processes for optimum yield, less operating cost, and quality of the extracted oil. This led to the identification of solvent type, extraction time, and extraction temperature as the factors that could be engaged for the determination of the quantity and quality of the extracted oil.

Fatima and Rahman (2020), Effects of a roasting temperature and duration on the quality of oil from walnut (plukenetia conophorum) using Random Surface Methodology, RSM. The obtained oil yields were between 30.67% and 33.87% at 87.57 oC, 25 min and 172.43 oC 25 min respectively. The optimum conditions were obtained at 160 oC and 40 mins with an oil yield of 33.50%. Abdulkareem et al., (2019) also analyzed the effectiveness of Box-Behn ken design of response surface methodology on the optimization of the mechanical oil extraction process from camellia oleifera seeds for its oil yield and energy consumption. From the experiments, it was revealed that oil yield and energy consumption from the mechanical extraction process are grossly affected by; moisture content, applied pressure, pressing temperature, and extraction time. The use of ANOVA revealed that the moisture content, applied pressure, and extraction time are significantly affecting total oil yield while applied pressure, pressing temperature, and extraction time have an obvious influence on energy consumption. Optimization is therefore concerned with the selection of the best method among the entire set via efficient quantitative methods

In this study, optimization of soxhlet oil extraction from baobab seeds is done using the grey relational analysis (GRA) as it is applicable in resolving the complicated inter-relationships between the multiple performance characteristics (Murugesan and Balamurugan, 2012). The Performance characteristics of the extracted oil such as the percentage oil yield (YLD) and the percentage free fatty acids (FFA) are chosen to evaluate the Soxhlet extraction process.

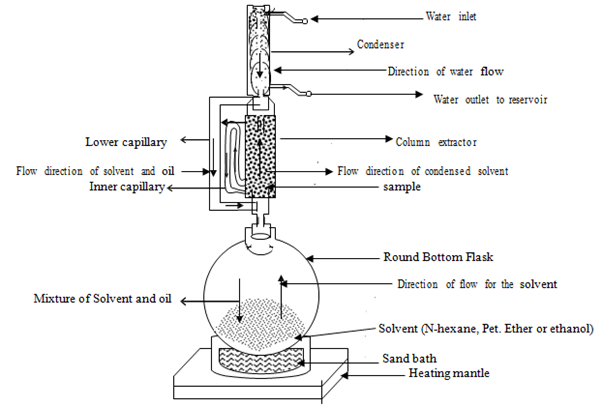

The seed of baobab was obtained from milk hawkers from Basawa, prepared, and milled to 1mm particle size. The extraction was done following the procedure reported by Buhari et al. (2014). The method involves the use of a Soxhlet extractor (mounted on a heating mantle) and the extraction solvents as arranged and shown in the schematic diagram in Figure (1). During the experiment, 50 g of n-hexane was measured and poured in a round bottom flask through a funnel, while 30 g of the powdered sample (baobab) in a filter paper was inserted in the center of the extractor column. The temperature of the heating mantle was set and maintained at 60 oC, while water at room temperature was allowed to flow through the attached condenser into the inlet of the attached pipe and leaves via the outlet end. When the solvent boiled, the vapor rose through the vertical tube into the condenser at the top where water was passing and condensing the rising vapor. The liquid condensate extracts the oil by dipping into the filter paper thimble at the centre which contained the powdered sample. The extract seeped through the pores of the thimble and filled the siphon tube, where it flowed back down into the round bottom flask. This was allowed to continue for a period of 80, 100, and 120 minutes respectively. A similar procedure was repeated while setting the heating mantle at 65 and 70oC respectively. This procedure was repeated using ethanol and petroleum ether as extraction solvents. A total of nine (9) experiments were conducted.

Figure 1: The schematic diagram for Oil extraction via Soxhlet extraction method (Source: adopted & modified from Asoiro and Akubuo, 2011)

The values obtained from the experiment were pre-processed since the range of the oil yield sequence differs from the free fatty acid sequence. Data pre-processing was used for altering the original sequence to a comparable sequence. Therefore, to pre-process the experimental results, the values were normalized between zero and one.

Percentage oil yield is the central response in the soxhlet extraction process which decides the suitability of any feedstock for sustainable biofuel production. A larger quantity of oil is required in this study hence, the "larger the better" performance characteristic became appropriate and the original sequence is normalized using the relationship in equation 1a (Shivapragash, et al., 2013; Pervez, et al., 2018 ; Pohit and Misra, 2013).

Where xi*(k) and xi(k) are the post-pre-processing and comparability sequence respectively, k=1 for YLD; i =1, 2, 3…,9 for experiment numbers 1 to 9.

Conversely, the smaller % free fatty acid is recommended for efficient biodiesel production via the trans-esterification method. Therefore, the smaller the better quality characteristic is used for minimizing the %FFA. Hence, the original data sequence was then normalized using equation 1b (Shivapragash, et al., 2013; Pervez, et al., 2018 ; Pohit and Misra, 2013).

Determination of the Grey Relational Grade (GRG)

Determination of the grey relational grade, a tool called Grey relational coefficient was used to express the relationship between the ideal and actual normalized experimental values. Equation 2 and 3 were used to determine the grey relational coefficient and the grey relational grades respectively (Shivapragash, et al., 2013; Pervez, et al., 2018 ; Pohit and Misra, 2013).

Where ∆oi(k) is the deviations of the reference sequence xo*(k) while, ∆min and ∆max are the minima and maximum deviations in the sequences and is the characteristic coefficient which is usually taken as 0.5 (Pervez, et al., 2018). The GRC (ξi) and GRG (γi) are computed and presented in Table 1. In the Table, the experimental runs were ranked based on the average values of the computed grade relational grade, while the effect of each extraction parameters on the total performance characteristics of the process was computed and tabulated in Table 2.

The experimental results obtained from the nine trials showed that the identification of the best extraction procedure would be confusing. This led to the use of an orthogonal array of Taguchi's method for the determination of the optimum process. Table 1 shows the computed normalized values, grey relational grades, and the ranks for the sample’s performance characteristics.

Table 1: Table of the performance characteristics and their grey relational grades

|

Trial |

Extraction results |

Normalized responses |

Responses Deviation( ) |

Grey Relational Coefficient ( ) |

Grey Relational Grade ) |

Rank |

||||

|

Yield (%) |

FFA (%) |

Yield |

FFA |

Yield |

FFA |

Oil Yield |

FFA |

|||

|

1 |

25.785 |

3.086 |

0.9381 |

0.2248 |

0.0619 |

0.7752 |

0.8899 |

0.3921 |

0.6409 |

3 |

|

2 |

26.825 |

2.805 |

1 |

0.4426 |

0 |

0.5573 |

1 |

0.4728 |

0.7364 |

2 |

|

3 |

25.340 |

2.086 |

0.9115 |

1 |

0.0884 |

0 |

0.8497 |

1 |

0.9248 |

1 |

|

4 |

21.641 |

2.525 |

0.6913 |

0.6596 |

0.3087 |

0.3403 |

0.6182 |

0.5950 |

0.6067 |

5 |

|

5 |

21.776 |

2.525 |

0.6993 |

0.6596 |

0.3006 |

0.3403 |

0.6245 |

0.5950 |

0.6097 |

4 |

|

6 |

16.781 |

2.525 |

0.4019 |

0.6596 |

0.5981 |

0.3403 |

0.4553 |

0.5950 |

0.5251 |

6 |

|

7 |

14.000 |

3.376 |

0.2363 |

0 |

0.7637 |

1 |

0.3957 |

0.3333 |

0.3645 |

8 |

|

8 |

14.081 |

3.366 |

0.2411 |

0.0077 |

0.7588 |

0.9922 |

0.3971 |

0.3350 |

0.3661 |

7 |

|

9 |

10.031 |

3.086 |

0 |

0.2248 |

1 |

0.7752 |

0.3333 |

0.3920 |

0.3627 |

9 |

From the table, it shows that experiment two has the highest oil yield; however, ranked second. Conversely, experiment three ranked first with the oil yield of 25.34% and the percentage free fatty acid 2.086%, while experiment nine ranked last. The optimum process was obtained using N-hexane at 70 oC and 120 minutes. The result was in agreement with that obtained by Wilson, et al., (2015) who used similar procedure for Baobab oil extraction and obtained a yield of 26.47% with n-hexane at 60 oC while, Ihab and Abubakar, (2015) obtained the optimum extraction temperature for desert-date sample using N-Hexane as solvent between 65-70 oC.

It has also been observed from the results that, a slight increase in the extraction temperature leads to the increase in the oil yield. This is attributed to the fact that, a rise in extraction temperature increases the diffusion rate of the solvent, which in turn enhances the oil’s solubility in the solvent, thus improve the extraction rate. However, increasing the temperature beyond the boiling point of a solvent may not have a significant effect on the extraction rate rather reduce the oil viscosity. This correlates with the findings of Khalid, et al., (2015) who revealed that the best extraction temperature using N-Hexane would be its boiling point to ensure maximum recovery. Similarly, according to Efthymiopoulos et.al., (2018), when high extraction temperatures are applied on the extraction solvents with high boiling point, it would result to thermal degradation of the extracted oils leading to the formation of free fatty acids. It is therefore recommended that, for efficient oil extraction through soxhlet extraction method, it is important to understand the synergy between the polarity of a solvent and its boiling point.

Effect of the Oil Extraction Parameters on the process Performance Characteristics

From Table 2, the results described the effect of extraction parameters on the baobab oil extraction process. The mean grey relational grade was found to be 0.5708 with ranges 0.402974, 0.066877, and 0.268099; for the type of solvent, extraction temperature, and extraction time respectively. The combination for the optimum process considered was A1B3C3 where A stands for solvent type, B for extraction temperature, and C for extraction time.

The main effect of each of the extraction parameters were presented in terms of ranking. It is obtained by determining the range from each row where the greater number ranked first. This shows that, among the three factors affecting the performance characteristics in the soxhlet oil extraction process, the selection of solvent is the most important step for higher oil yield and lower free fatty acid. The computed values for the influence of the extraction parameters showed that, type of solvent lead with 55% followed by extraction time, 36% and lastly the extraction temperature, 9%.

Table 2: Effect of extraction parameters on the soxhlet oil extraction process

|

Symbol |

parameters |

levels |

Main effect (max-min) |

Rank |

||

|

1 |

2 |

3 |

||||

|

A |

Solvent |

0.767423* |

0.580531 |

0.364449 |

0.402974 |

1 |

|

B |

Rxn Tempt. |

0.537376 |

0.570774 |

0.604253* |

0.066877 |

3 |

|

C |

Rxn. Time |

0.364449 |

0.604253 |

0.632548* |

0.268099 |

2 |

Oil extraction using soxhlet method has been one of the most commonly employed techniques; however, the cost of solvent has since become one of its drawbacks in its usage for commercial purposes. In an attempt to provide solutions to the challenges associated with the method, optimization of the extraction process was carried out following Taguchi's orthogonal array using the grey relational analysis to test some of the parameters affecting the performance characteristics while determining the level of influence by each factor. Those factors are; solvent type, extraction temperature, and extraction time.

The results from the optimization process revealed that the third trial was found to be the best among the total of nine trials with 25.34% oil yield and 2.086% free fatty acid. This showed that the best combination with optimum values is A1B3C3(N-hexane, 70 oC and 120 minutes). In addition to that, the grey relational analysis was also used in determining the level of influence by each factor. The solvent type has the greatest level of contribution in the extraction process with 55% followed by the extraction time of 36% and lastly the extraction temperature of 9%.

Abdulkareem A.S., Uthman H., Afolabi A.S., and Awenebe O.L. (2019): Extraction and Optimization of Oil from Moringa Oleifera Seed as an Alternative Feedstock for the Production of Biodiesel

Asoiro, F.U., and Akubuo, C.O. (2011). "Effect of Temperature on Oil Extraction of Jatropha curcas L. Kernel". Pacific Journal of Science and Technology. 12(2):456-463

Buhari, M., Danbature, W. L., Muzakir, M. M. and Abubakar, B. A. (2014): Production of Biodiesel from Baobab Seed Oil, Greener Journal of Agricultural Sciences 4(2):22-26, ISSN: 2276-7770.

View ArticleDivine B.N and Anuanwen C.F (2020): Optimization methods for the extraction of vegetable oils: a review, journal of processes 8(209): 2-21

View ArticleEfthymiopoulos, I. Hellier, P. Ladonmatos, N. Russo-Profili, A. Eveleigh, A. Aliev, A. Kay, A. and Mills-Lamptey, B (2018): Influence of solvent selection and extraction temperature on the yield and composition of lipids extracted from spent coffee grounds, Journal of crops and products, 119:49-56, hosted by Elsevier,

View ArticleFatima A., R., & Rahman, A. (2020): Effect of Roasting Temperature and Duration on the Quality of Oil from Walnut (Plukenetia conophorum) using response surface methodology, Asian Food Science Journal, 13(4):1-12

View ArticleHasan A. M., Mohammad M., Rowsonozzaman R. M. and Rakibul Hossain A. (2013): Biodiesel from Neem oil as an alternative fuel for Diesel engine. Proceeding Engineering, 5th BSME International Conference on Thermal Engineering Bangladesh, 56:625 - 630, ISSN: 1684-5315

View ArticleIhab S. and Abubakar E. (2015): Parameters Optimization, Modelling, and Kinetics of Balanites Aegyptiaca Kernel oil extraction, International Journal of Chemical Engineering and Applied Sciences, 5(1): 1-4

Khalid M. A, Badoor M. K, and Basma A. A (2015): Extraction and Modelling of Oil from Eucalyptus camadulensis by Organic Solvent, Journal of Materials Science and Chemical Engineering, scientific research publishing

Mălina, A., Anicuţa S., Tănase, D. and Marta, S (2014): Extraction Of Vegetable Oils From Ground Seeds By Percolation Techniques, U.P.B. Sci. Bull., Series B, 76(2):13-22, ISSN 1454 - 2331

Maria Y L., Natan, F. A., Widiyanti, P., Ikasari, D., Indraswati N. and Soetaredjo, F. E. (2008): Extraction of Neem Oil (Azadirachta Indica A. Juss) Using N-Hexane and Ethanol: Studies of Oil Quality, Kinetic and Thermodynamic, ARPN Journal of Engineering and Applied Sciences, 3(3):49-54

Murugesan, S and Balamurugan, K (2012): optimization by grey relational analysis of EDM parameters in machining Al-15%SiC mmc using multihole electrode, Journal of applied sciences, 12:963-970. Doi:10.3923/jas.2012.963.970

View ArticleNaimah Sahad, Ayub Md. Som and Alawi Sulaiman (2014): Review of Green solvents for oil extraction from Natural products using different extraction methods, Journal of applied mechanics and materials, Trans Tech Publications, Switzerland, 661: 58-62.

View ArticlePervez, M. N., Shafiq, F., Sarwar, Z., Jilani, M.M and Cai J (2018): Multi-Response Optimization of Resin Finishing by Using a Taguchi-Based Grey Relational Analysis, Journal of Materials, 11 :426 (1-19) doi:10.3390/ma11030426 PMid:29543724

View Article PubMed/NCBIPohit, G and Misra, D (2013): Optimization of performance and emission characteristics of diesel engine with biodiesel using grey- Taguchi Method, Journal of Engineering, 2013:6-12 Hindawi Publishing Corporation

View ArticleSaidat Olanipekun Giwa, Seer MercyAkaagerger, Maryam Ibrahim and Abdulwahab Giwa (2016): Production of Biodiesel from Desert Date Seed Oil. International Journal of ChemTech Research, 9(6):453-463,.

Salvi, B.L. and Panwar N.L. (2012): Biodiesel resources and production technologies - A review, Renewable and Sustainable Energy Reviews, Elsevier, 16:3680-3689

View ArticleShivapragash, B. Chandrasekaran, K. Parthasarathy, C and Samuel, M (2013): Multiple Response Optimizations in Drilling Using Taguchi and Grey Relational Analysis, International Journal of Modern Engineering Research (IJMER), 3(2):765-768, ISSN: 2249-6645

Wilson L. D., Fai F. Y., Buhari M. and Yoro M (2015): Effect of Seed Strorage on the Physico - Chemical Properties of its Oil (Adansonia Digitata), International Interdisciplinary Journal of Scientific Research, 2(1): 1-7, ISSN: 2200-9833