Processing of solid wastes from mines, mineral processing and metallurgical plants-a conceptual case study of small size iron-steel industry, Ballari area , Karnataka, India

Corresponding Author

Email:ravibelavadi@gmail.com

Affiliation

B.P.Ravi, P.S.Kumar and C.Rudrappa

Mineral Processing Department,

VSKU PG Centre, Nandihalli, 583119

Article Reviewed By:

Kuixin Cui(kxcui2010@csu.edu.cn)

Sezen Coskun(sezencoskun@sdu.edu.tr)

Chengyan Wang(chywang@yeah.net)

Citation

B P Ravi, Processing of solid wastes from mines, mineral processing and metallurgical plants

Abstract

The case studies of processing of low grade iron ore fines from iron ore mines, processing of iron ore beneficiation plant tails have been discussed where in the pellet grade concentrate and cement grade iron concentrate were produced at 75 wt% of ROM and 50 wt% yield of plant tailings equivalent to 12.5 wt% yield of ROM . This indicated that the low grade mine dumps and plant tailing quantum can be reduced to 25 and 50% area respectively reducing waste management cost, besides generating value earning concentrates and hence is being industrially implemented. Proper characterization of wastes in secondary steel unit and processing has led to increasing the reuse by 50% from base level. Tunnel kiln brick making using clayey wastes from iron ore mines - silts from tank beds, reprocessed plant tails and solid wastes from DR plants has led to nil waste sustainable process where all the wastes from mine, mineral processing plant tails and solid wastes from DR Iron plants from Ballari area, Karnataka, India, are used.

Introduction

Global survey confirms that environmental concerns (40%) closely followed by social concerns (30%) continue to be the top sustainable development issues for the mining and metals industry agenda[1]. Karl Marx quoted “Human Projects that ignore the great laws of Nature brings only disaster”. The paradoxical balance between maximum profit oriented policy and pollution free society must be resolved by reprocessing waste and restoring such materials into harmless substances for reuse. The vexed problem associated with waste management from mineral based industries like mines, mineral processing and metallurgical plants are slightly different, as we have to deal with non- renewable, heterogeneous, site specific, long gestation period and low technology industries located in remote geographical areas with least infrastructure with unskilled manpower. The review of literature on concepts of processing of mining wastes, washing – mineral processing plant tails and wastes from iron and steel metallurgical process plants are vast and scattered as enumerated by previous works [4-7]. However, the literatures on adaptation of these concepts industrially are limited [2-4]. It is in this context an effort is made to report the concepts and industrial case studies of processing iron ore mine low grade dumps, iron ore beneficiation plant tails and ferrous metallurgical wastes yielding usable products for diverse industries thereby solving vexed problem of waste management and conservative step meeting the demand for supply of quality raw materials. Indian Iron ore occurs mostly as oxides in nature. The deposits are fairly well distributed in the states of Jharkhand, Chattisgarh, Orissa, Karnataka, Maharashtra, Goa and Andhra Pradesh[16&17]. The lack of consistency with respect to the ratio of Al2O3 to SiO2 make these ores unsuitable for direct use in the blast furnace [1-3] and needs beneficiation to industrial use. The iron ore minerals are liberated from gangue minerals by ball mill grinding, followed by hydrocycloning, gravity concentration of sand by spiral concentrators and WHIMS of spiral tails producing BF grade concentrates.

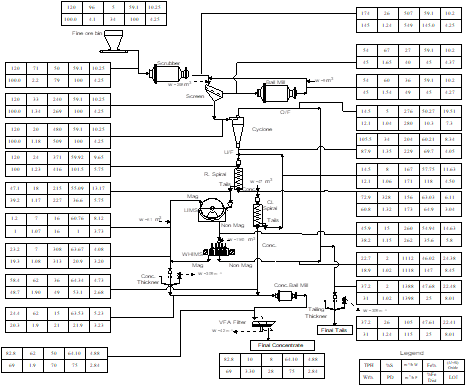

Bellary-Hospet-Sandur belt in Karnataka is one of the five prominent Precambrian Banded Iron formations wherefrom hematite type ore is mined for iron - steel making. In order to meet the projected demand of 200 million tons steel production and to maintain long term iron ore export contracts, about 600 million tons of iron ores and concentrates are required. The review of literature indicated that extensive work has been done by IBM, CSIR labs, NMDC, TATA etc for conservation of values.. A sub grade iron ore sample from SJH mine, Sandur, Karnataka state was collected for evolving a process producing pellet grade concentrate assaying Fe>63%, SiO2 + Al2O3 <6%for steel manufacture by DRI Technology. The industrial implementation of the beneficiation project data at BMM established the mid-sized secondary steel manufacturer established a concentrator and pelletization plant producing 1 MTPY BF grade pellets for export and for its sponge iron plant by utilizing sub-grade iron ore fine dumps from the region. The beneficiation process comprises of closed circuit screen - ball mill grinding of iron ore fines to – 0.5 mm, desliming by cycloning, spiraling of cyclone underflow , HGMS of spiral tails, open circuit grinding of concentrate (thick pulp) followed by pressure filtration yielding BF grade pellet concentrate. Fig 6 shows the process flow-sheet. . During the preparation of ore as a feed to blast furnace a significant amount of slimes (-0.050 mm ) and non magnetic tails are being generated [6]. The tails assaying 30-45 %Fe are deposited to tailing pond.. The iron ore beneficiation have resulted in production of millions of tons of slimy tails stacked tail pond necessitating a suitable beneficiation process for recovering the iron values from the perspective of mineral conservation, effective space utilization of the tailing ponds and to enhance the life of the existing operating mines. The improvement in the environmental regulations, fresh lease of land for tails impoundment is next to impossible and mitigation of vexed tailing pond management with little environmental problem of silting, dust and ground water contamination is getting complicated as the time passes on. Iron ore is also used in cement industry and accounts for 3% total consumption of iron ores. The specifications of iron ore for use in cement industry is Fe (T) 50% Min., SiO2 (T) 15% Max, SiO2 (Free) Max 10%, TiO2 Max 4%, S and P Max 0.1%. or it can be used as a blendable pellet grade Hence an attempt was made to study the amenability of iron ore beneficiation plant tails from Bellary, Hospet and Sandur region to produce cement grade iron ore concentrates or blendable pellet grade . The tails are produced after subjecting the sub grade iron ore mostly anhydrous type to scrubbing, classification, grinding to liberate the values, gravity concentration and wet high intensity magnetic concentration yielding pellet grade concentrates, while the WHIMS-spiral tails and untreated slimes constitute the final tails dumped in the tailing pond. The tails were collected from tailing ponds of the beneficiation plant to study the amenability of the sample to produce cement grade iron ore concentrates. The review of literature on processing of Indian iron slimes is enormous where in centrifugal concentration devices, selective dispersion – selective flocculation, inverse cationic column flotation, wet high intensity magnetic separation (WHIMS)/ High gradient magnetic separation (HGMS) have been used.[9-17] However the most of the work on industrial scale centers either on either inverse cationic column flotation[11] or HGMS[12]..

The 0.6 MTPA integrated steel plant and 130MW Captive power plant is being operated near Hospet. It is producing 0.63MTPA mild steel billets, 0.6MTPY pellets and generates 260 GWhPY. Currently the above plant consumes 1.8 MTPY low grade iron ore for beneficiation plant, 1.25 MTPY concentrate produced is pelletized by Grate-Kiln method. 0.6MTPY Pellets is sold to other nearby plants. The remaining 0.65MTPY pellets is reduced in DR kilns yielding 0.45 MTPY DRI which is mixed with 0.33MTPY Steel scrap producing 0.6MTPYliquid steel. The power plant generates 100 MW and 30MW is regenerated from waste heat boilers of DR plant and needs 0.72 MTPY coal and 0.75 MTPY Water

Materials & Methods

2.1 Material

About 1 ton of sub grade iron ore sample from SJH mine, Sandur, Karnataka state was received for evolving a process producing pellet grade concentrates for steel manufacture. The slime sample from tailing dams of iron ore beneficiation plant of BMM Ispat ltd, Hospet was collected and sub samples were drawn after homogenization followed by coning and quartering method. Dolochar and fly ash from DRI plant of BMM Ispat Ltd were collected.

2.2 Equipment

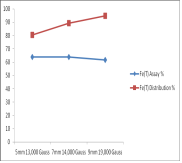

250 x150mm Roll crusher, Carpco riffler, Tyler sieve set, Denver 175 x 350 mm tumbling mill with 13.5 kg 25 mm steel balls/ 19 mm to37.5mm steel rods/25mm x 25mm cyl pebs, Denver Laboratory diagonal deck table, Mozley 50 mm cyclone test rig, Eriez 4x3 lab WHIMS, Larox lab filter, pan filter, drying oven and balances. Mozley hydro cyclone [10.25 and50 mm dia] test rig was used for desliming if needed. The particle size analysis was done by classical method. Lab model WHIMS was used for carrying out lab tests while Vertical pulsating wet high intensity magnetic separator [VPWHIMS] of LONGI make [LGS-EX 500] was used to confirm the findings. Initially tests were carried out varying the %Solids[10/25/40], desliming [ as it is and desliming 10 microns], intensity [10,700, 13,300 and 15,200 gauss], matrix rod size [ 1/1.5/2mm] pulsation frequency [75/150/225 cycles / minute and rpm [2/2.5/3] This was followed up with a cleaner and scavenger stage at 15 and 25% S and 10700 and 15200 gauss respectively for improving the grade and recovery.

2.3 Method

Standard feed preparation and sampling methods, laboratory testing methods , mineralogical and assay methods enumerated by hand books were followed. The experimental work has been categorised as characterisation, physical concentration, other auxiliary tests and final flow sheet results.

Results

The results are divided into three types viz process evolution for low grade ores, process auditing of industrial beneficiation plant, process evolution of beneficiation plant tails for producing cement grade or blendable pellet grade concetrates and processing of DR plant rejects and utilization.

3.1 Process evolution for low grade iron ores producing pellet grade concentrates

3.1.1 Characterisation of low grade ore: The as received sample was subjected to standard feed preparation, sampling, physical, chemical and mineralogical studies. The ROM consisted of mostly brown coloured fines with dark grey coloured hard – compact chips The sample analysed 52.65% Fe(T), 19.65% SiO2,2.57 %Al2O3 and 2.09% LOI. The sample contained mainly fine to medium grained hematite with subordinate amounts of quartz. Fine grained feldspar, gibbsite and very fine grained magnetite were found in minor to trace amounts. Hematite aggregates are liberated fairly at 50 mesh size. The mineralogical amenability test [sink and float test] on deslimed minus100 mesh sample yielded pellet grade concentrate indicating that the siliceous iron ore fines sample is amenable to beneficiation.

3.1.2 Amenability of low grade ore sample to size: Dry size analysis of ROM showed that the sample was fine in nature. Wet size analysis of as received fines yielded a marginally Fe enriched sand fraction. The wet sieve analysis of – 10 mesh fraction also yielded a coarse sand fraction[ + 100 mesh] with enhanced Fe values of + 60%.The above tests indicated that Fe values marginally taper at fine sizes, thus removal of clayey slimes improves the grade marginally. The sample is amenable to size refining as log washing and sizing / classification may yield sandy concentrates close to low grade sinter grade but failed to meet the stipulated 63% Fe.

3.1.3 Grindability tests: As the liberation data revealed that the fair degree of liberation of iron mineral aggregates are below 50 mesh and concentrates meeting high quality pellet grade has to be produced, the batches of 2 kgs of representative -10 mesh samples were ground in 175x350 mm tumbling mill with 13.5 charge at 67%S to different sizes either in stages to a stipulated mesh size, with rod/ l charge.

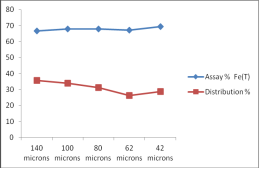

3.1.4 Tabling tests varying mesh of grind: Gravity concentration tests by tabling were conducted varying rod mill stage ground MOG [-50mesh d80 140 microns, -70mesh d80 100 microns, -100 mesh d80 80 microns, -150 mesh d80 62 microns and -200 mesh d80 42 microns]. The results are shown in Fig 1. Increase in fineness of stage ground MOG marginally increased the concentrate grade and significantly reduced the Fe recovery at sizes finer than -50 mesh. A concentrate assaying 66.56% Fe(T), 3.08% SiO2, 0.54% Al2O3, and 0.96% LOI with 35.6 % Fe recovery at wt% yield of 28 was obtained at optimum MOG of minus 50 mesh (d80 140 microns).

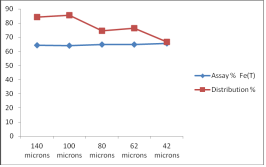

3.1.5 WHIMS tests: Wet high intensity tests were conducted [1] varying mesh of grind -50/-70/-100/-150/-200 mesh] keeping other factors like intensity/current, ball matrix etc constant [2] varying ball matrix size [6/9/12mm dia] keeping other factors like MOG and current etc constant [3] varying intensity by varying current [{1/2/3/ 4 Amps}/{7000/9000/13000/15000 Gauss}] keeping other factors constant. [4] Varying the %Solids[10/25/40%Solids][5] Tests under optimum conditions with a cleaner and scavenger step on un-deslimed and deslimed [25microns] pulp. The results are shown in Figures 3 to 5 respectively. The WHIMS test indicated that; 1) Increase in fineness of MOG significantly reduced %Fe recovery. 2) Increase in matrix ball diameter significantly reduced % Fe recovery. 3) Increase in current and field intensity from steadily increased %Fe recovery. WHIMS test on deslimed feed with cleaner yielded marginally higher grade concentrate as compared with un-deslimed feed, with a significant drop in % Fe recovery due to slime loss. WHIMS at -200 mesh grind could yield a pellet grade concentrate assaying 65.89%Fe with 63.8% Fe recovery at 51% yield.

3.1.6 Final test under optimum Tabling followed by WHIMS: Most of the recommended processes for iron ores indicated gravity concentration followed by WHIMS.. The results of conventional process under optimum conditions are given in Table1. The test was also repeated for aluminous iron ore to know the effect of ore variability which also produced a pellet grade concentrate assaying 63.57%Fe with 76.7 % Fe distribution at weight % yield of 70.0.. The metallurgical results for base line mixed ore, clayey iron ore and siliceous iron is given in Table 1. The results indicated that the processing of clayey iron ore in conventional circuit yielded tails with high % Fe as compared to processing of siliceous iron ore similar to that of previous works[14 & 15].

3.2 Industrial implementation of the project and auditing of beneficiation plant

The mid-sized secondary steel manufacturer established a concentrator and pelletization plant producing 1 MTPY BF grade pellets for export and for its sponge iron plant by utilizing sub-grade iron ore fine dumps from the region. The process comprises of closed circuit screen - ball mill grinding of iron ore fines to – 0.5 mm, desliming by cycloning, spiraling of cyclone underflow , HGMS of spiral tails, open circuit grinding of concentrate (thick pulp) followed by pressure filtration yielding BF grade pellet concentrate. Fig 6 shows the process flow-sheet. The historical ore variability data indicated that the goethite (3-35%), hematite (45-75%), aluminous gangue mineral (1-20%), slimes (6-26% minus 45 microns), and Bond’s work index (7-12Kwh/short ton) and Bond’s work index of concentrate was 20kwh/t . The metallurgical results for base line mixed ore, clayey iron ore and siliceous iron is given in Table 2. The results indicated that the processing of clayey iron ore in conventional circuit yielded tails with high tails value > TLV value of 45% Fe as compared to processing of siliceous iron ore. The findings are similar to that of previous works[14 & 15]. By process auditing the wt.% yield of concentrates was raised to a minimum of 75 wt.% yield and final tail value was limited to <45% Fe with pellet grade concentrates assaying >63% Fe even for the refractory clayey iron ore with high slimes content

3.3 Process evolution for processing of slimy tails from beneficiation plant tailing dam

The slimy plant tails were subjected to characterization studies and WHIMS Concentration followed by gravity concentration of slimy WHIMS magnetic concentrates.

3.3.1 Characterization studies;- The representative samples were subjected to chemical analysis by classical methods, the mineralogical studies , particle size analysis by classical fine sieve and sub sieve analysis methods. The sample assayed 44.12% Fe(T), 20.02% SiO2, 9.32% Al2O3 and 8.40% LOI. The sample was slimy in nature with D100 200 microns, D80 15 microns and 70% -10 microns. Empirical mineralogical studies indicated that the brownish yellow coloured powdery sample contained mainly goethite, subordinate amounts of hematite and ferruginous clay with minor amounts of quartz. The split process diagnostic test at 500 mesh size comprising of heavy liquid separation using TBE [SG 2.9] followed by DHIHG magnetic separation using Franz Iso dynamic separation of sinks yielded concentrates assaying 60% Fe indicating the sample is amenable to split WHIMS –WHGMS and centrifugal gravity separation similar previous characterization studies.[25]

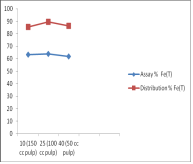

3.3.2 Magnetic separation and gravity separation studies; Desliming at 10 microns could yield a cyclone over flow assaying 46.21 % Fe at 90% Fe distribution with 86 wt.% yield and the deslimed sand assayed 31.50% Fe. Initially tests were carried out varying the %Solids[10/25/40], desliming [ as it is and desliming 10 microns], intensity [10,700, 13,300 and 15,200 gauss], matrix rod size [ 1/1.5/2mm] pulsation frequency [75/150/225 cycles / minute and rpm [2/2.5/3] This was followed up with a cleaner and scavenger stage at 15 and 25% S and 10700 and 15200 gauss respectively for improving the grade and recovery. The results indicated that

- An increase in intensity increases the wt% yield and % Fe distribution of concentrate, but decreases the grade of concentrate. The tails value decreases significantly with increase in intensity.

- An increase in frequency decreases the wt% yield, % Fe recovery and increases the grade of concentrate. But low frequency produces concentrates with low grade and recovery. Optimum values lie at medium levels and is dependent on granulometry of material.

- An increase in rpm insignificantly decreased the grade of concentrate and significantly increased the wt% yield and % Fe distribution of concentrate.

- Desliming and split concentration of slimes and sand separately yielded good results.

- The matrix size indicated that finer matrix size increased recovery of slimy values with a marginal drop in grade and depended on feed granulomentry

- The %S indicated that dilute pulps yielded better quality concentrate at the loss of values.

- Scavenging tests at very high intensity of 13000 gauss, 35%S,1-1.5mm rod matrix low rpm, low pulsation rate yielded high recoveries and low Fe values in non magnetic tails, though the grade of concentrate was close to cement grade [Fe~50%, Free silica <15%]

- Cleaner tests on rougher concentrates at moderate intensity of 6000 -8000 gauss,10-15% S, 2 mm dia rod matrix, high rpm, high pulsation rate yields high grade concentrates meeting pellet specifications[Fe >63%].

- Siliceous ore slimes responded well as compared with aluminous hydrated iron oxides and Low grade slimes with % -0.01mm >90, LOI>9 yielded cement grade concentrate only. VPHGMS performed better than conventional WHIMS yielding concentrates with higher yield,% Fe grade, Fe distribution% and with selectivity[12].

The final process flow sheet comprising of split concentration at 10 microns by cyclone and Rougher WHIMS at 10000 gauss, Scavenging WHIMS of R tails at 13000 gauss, Cleaner WHIMS of Rougher concentrate at 8000 gauss in counter circuit configuration with dewatering of recirculating loads [ Cl. tails and Scavenger concentrate with Cyclone over flow feed slimes] yielded a concentrate assaying 60.2% Fe, with 70 % Fe distribution at wt.% yield of 51.3. Efforts are on to reprocess the slimy magnetic concentrate in FM1 Spirals to recover metallurgical grade concentrates. The best result of trials [Table 4] yielded a [1] pellet grade concentrate assaying 63.54% Fe, 3.39% SiO2, 2.71% Al2O3 and 2.70% LOI with 7.2 % Fe distribution at wt% yield of 5 .[2] A cement grade concentrate assaying 59.80% Fe, 3.15 % SiO2, 5.35% Al2O3 and 5.80% LOI with 61% Fe distribution at wt.% yield of 45.[3] The tails comprising of non mag fraction from sand and slime circuit assayed 27.17% Fe may find application in brick manufacture.

3.4 Process evolution of wastes from secondary steel plant and subsequent utilization

The 0.6 MTPA integrated steel plant and 130MW Captive power plant is being operated near Hospet. It is producing 0.63MTPA mild steel billets, 0.6MTPY pellets and generates 260 GWhPY. Currently the above plant consumes 1.8 MTPY low grade iron ore for beneficiation plant, 1.25 MTPY concentrate produced is pelletized by Grate-Kiln method. 0.6MTPY Pellets is sold to other nearby plants. The remaining 0.65MTPY pellets is reduced in DR kilns yielding 0.45 MTPY DRI which is mixed with 0.33MTPY Steel scrap producing 0.6MTPYliquid steel. The power plant generates 100 MW and 30MW is regenerated from waste heat boilers of DR plant and needs 0.72 MTPY coal and 0.75 MTPY Water. The mass balance of inputs and products is given in table 5 below. The above data indicated that about 20% of solid waste generated fed back to the steel unit.

3.4.1 Conventional waste utilization mode; Currently the possibility of reusing by reprocessing the wastes is limited to the dust in pelletization, char in power plant scale, coal gas in DR plant and waste scrap in steel melting accounting of 30% of solid waste reuse [0.72MTPY] [3 &4]. The dolochar was subjected to gravity and magnetic separation to concentrate coal light fraction, magnetic heavy iron phase fraction and non magnetic heavy dolomite fraction with size reduction to -0.5mm. The coal is reused for fuel and mineral matter like dolomite, silicate and iron phases may be used in cement industry, especially the latter. ].. It is being implemented at BMM Ispat Ltd., Danapur.

3.4.2 Evolution of nil waste process; Alternatively the final tail 0.45 MTPY, Fly ash 0.06 MTPY, 0.05 MTPY crushed dolchar, 0.1 MTPY char and/or 0.90 MTPY clayey inorganic silt obtained by desilting of tank beds/ iron ore mine clay dumps may be used for brick making by tunnel kiln method consisting of crushing to -0.3mm, mixing, vacuum extruding, auto brick cutting and loading trolleys, drying in tunnel, firing at9000C in tunnel kiln and cooling The specifications are Fe <21%,SiO2 >45%, Al2O3 > 15% CaO+MgO>5% and -3mm size. The above dried material is pulverized and mixed with 10-15% water. The wet mass is compressed and placed in cage to be cut by wires. The wet cut bricks in cage are lifted and transported into firing unit where it is dried at 1050 C and moved to firing chamber for firing at 6000C followed by cooling. The above process takes 2 days. But the latter project is seasonal and will not able to work during rainy season due lack of supply of clayey silt from tanks and has to depend on reprocessed tails. The process is a nil waste process, helps desilting of tank – reservoir beds and uses the all wastes obtained in desilted material - top clayey soil over burden dumps from mines, beneficiation plant tails and wastes from sponge iron making plants. Currently reprocessed final tails 0.1MTPY[ for producing 0.6MTPYpellet & 0.1MTPY Cement grade concentrates], Fly ash 0.04 MTPY, crushed processed dolochar 0.04MTPY and char 0.11MTPY produced 600tpd bricks of 200 x 100 x 75 mm each weighing 3 kg producing 2 lakh bricks per day. Thus the nil waste process utilizes 0.8 MTPY low grade ore from iron ore mines producing 0.63MTPY steel billets [from 0.6 MTPY pellets and0.31MTPY steel scrap], 0.2MTPY bricks, 0.1 MTPY cement grade Fe concentrate. M/s VSL[A] group has established a plant and reported to be producing 1 lakh bricks per day. The comparative material balance of conventional and non-conventional mode of waste processing, recycling and reusing on an integrated mode in case of low grade ores from iron ore mines, lron ore beneficiation plant tails and secondary steel manufacture wastes is given in Table 6.

Conclusion

Careful characterization followed by separate stacking of wastes either at mine sites, beneficiation plant tailing area and metallurgical industries waste area has helped the processing people to process and reuse them back in the industry. The non-conventional mode comprising of beneficiation of low grade ore wastes, reprocessing of beneficiation plant tails, processing of metallurgical plant wastes, and reprocess plant tails in brick manufacture, recycling metal and fuel value in metallurgical plant has reduced waste to nil. The integrated non-conventional plant comprising of beneficiation, pelletization, DRI production and SMS consumes 100 tph low grade ore, 100 tph coal, 50 tph scrap, 30 tph alkaline earth fluxes - SMS additives and generates 100MW/h surplus power, 90 tph steel and 25 tph bricks [2 lakh bricks / day]

Images and Tables

Conditions:

[1]. ROM ground to -50 mesh, d80 140 microns. [2]. Diester diagonal deck table. 10mm stroke, 200 rpm frequency, Full tilt [0.333],0.5lpm 25% solids pulp, Feed water3.5lpm Dressing wash water 6.5lpm [3]. Table rejects and slimes ground to -150 mesh after natural settling. Ground product subjected to WHIMS 3X4L Outokumpu Carpco model. 1LPM wash water, Ikg ball matrix,feed/wash cycle 1 min each –locked cycle test done as below [4]. I and II cleaner non mag tails and Scavenger mag recycled back [5]. Thickening - filtration of ground final concentrate and final tails.

|

Stage |

Dia mm |

Amps |

Volts |

KW |

Gauss |

%Solids |

Feed lpm |

|

Rougher |

9 |

3 |

200 |

0.75 |

17000 |

40 |

0.1 |

|

Scavenger |

9 |

4 |

300 |

1.00 |

19000 |

30 |

0.15 |

|

ICleaner |

7 |

3 |

200 |

0.75 |

12000 |

10 |

0.2 |

|

II Cleaner |

5 |

2 |

150 |

0.50 |

10000 |

10 |

0.2 |

Results

|

Products |

Present Siliceous Fe ore |

Clayey iron ore |

||||

|

Wt. % |

%Fe assay |

%Fe dist. |

Wt. % |

%Fe assay |

%Fe dist. |

|

|

-50mesh Table concentrate |

45.8 |

66.56 |

58.2 |

50.0 |

65.00 |

56.7 |

|

-150 mesh II cleaner WHIMS concentrate |

28.0 |

59.47 |

31.8 |

20.0 |

60.00 |

20.7 |

|

Non mag tails |

26.2 |

19.98 |

10.0 |

30.0 |

45.00 |

23.3 |

|

Head [Cal] |

100.0 |

52.36 |

100.0 |

100.0 |

58.00 |

100.0 |

|

Composite concentrate |

73.8 |

63.82 |

90.0 |

70.0 |

63.57 |

76.7 |

|

Products |

Design mixed typical ore |

Clayey iron ore |

Siliceous iron ore |

||||||

|

Wt.% |

Assay % |

% Dist. |

Wt.% |

Assay % |

% Dist. |

Wt.% |

Assay % |

% Dist. |

|

|

Cyclone O/F |

9.4 |

55.00 |

8.8 |

12.1 |

50.27 |

10.3 |

11.2 |

45.70 |

8.8 |

|

I Cl. Sp. Conc. |

48.9 |

66.60 |

55.2 |

48.7 |

64.34 |

53.1 |

56.5 |

64.21 |

62.6 |

|

Mag.Conc. |

19.0 |

61.17 |

19.7 |

20.3 |

63.53 |

21.9 |

18.0 |

62.67 |

19.5 |

|

Non-Mag tails |

22.7 |

42.36 |

16.3 |

18.9 |

46.02 |

14.7 |

14.3 |

36.64 |

9.1 |

|

Head(Calc.) |

100.0 |

59.00 |

100.0 |

100.0 |

59.01 |

100.0 |

100.0 |

57.92 |

100.0 |

|

Final Tails |

32.1 |

46.20 |

25.1 |

31.0 |

47.68 |

25.0 |

25.5 |

40.62 |

17.9 |

|

Final Conc. |

67.9 |

65.08 |

74.9 |

69.0 |

64.10 |

75.0 |

74.5 |

63.84 |

82.1 |

|

Product |

OA Wt.% yield ROM |

Wt.% yield |

% Fe Assay |

% Fe Distn. |

|

FM 1 Spiral concentrate of CyOFCl Mag -Pellet grade |

1.25 |

5.0 |

63.54 |

7.2 |

|

FM 1 Spiral tails of CyOFCl Mag -Cement grade |

11.25 |

45.0 |

59.80 |

61.0 |

|

Cy OF Sc Non mag – slimy tails |

9.00 |

36.0 |

27.82 |

22.7 |

|

Cy UF – sandy tails Cl Mag |

0.325 |

1.3 |

61.09 |

1.8 |

|

CyUF- sandy tails Sc Non mag |

3.175 |

12.7 |

25.36 |

7.3 |

|

Head Cal Tails |

25.0 |

100.0 |

44.12 |

100.0 |

|

Cl Mag Conc |

12.825 |

51.3 |

60.20 |

70.0 |

|

Final tails |

12.175 |

48.7 |

27.17 |

30.0 |

|

Main plant concentrate |

75.000 |

|

63.50 |

- |

|

Final composite concentrate |

87.825 |

- |

63.02 |

- |

|

Feed ROM |

100.000 |

- |

58.65 |

- |

|

Inputs in MTPY |

Out puts in MTPY |

||

|

Low grade iron ore 54-58% Fe, SiO2 <13%, Al2O3<9, LOI< 6% |

1.80 |

Steel billets |

0.63 |

|

Pellets |

0.60 |

||

|

Limestone CaO >50%, SiO2<6% LOI <1% |

0.11 |

Coal gas |

0.04 |

|

Tar from coal gasification plant |

0.01 |

||

|

Dolomite MgO>15%,CaO>30%,LOI >40% SiO2+Al2O3<2.5% |

0.05 |

Fly ash [Fe<10%, CaO>15%, MgO <5%, Silica >50% , reactive silica>20% and alumina >20%] |

0.06 |

|

Scale, Muck and waste scrap |

0.03 |

||

|

Non coking coal Ash<17% CF>6KCal |

0.72 |

Dolochar Fe<10%, CaO+MgO <10%, Silica and alumina >50% FC> 20% |

0.05 |

|

Steel scrap |

0.31 |

Dust |

0.03 |

|

Bentonite - Na swelling type |

0.01 |

Char |

0.10 |

|

Additives to SMS |

0.03 |

BP tailings |

0.45 |

|

Water |

0.75 |

Losses |

1.78 |

|

Total |

3.78 |

Total |

3.78 |

References

C.Kumar, S.K Singh. and Annaya Roy, (2013), , Proc. MPT 2013 MPT 2013, IMMT Bhubaneshwar, Vol 3, PP958-67.

R.Singh, S.C. Maulik, S.Rafiuddin, R.K. Kunwar, B.Banerjee and S.K.Sil, (1996),? Recovery of values from mining and industrial wastes?, Proceedings: NS-EWM 1996 ? NML Jamshedpur. pp.75-S5

S. K. Gupta, J. K. Tandon, D. N. Ghorai, P. K. Pal and P. K. Sarkar,(2004), ?Transforming Steel Domain Green Through Innovative Waste Management - A findal Approach?, Proc. Environmental & Wrste Management, pp153-164.

V.I.Lakshmanan, R.Roy and V.Ramachandran,(2016), ? Innovative Process Development in Metallurgical Industry -Concept to Commission?, ISBN 978-3-319-21599-0 (eBook), Springer International Publishing Switzerland

B.P.Ravi, M.P.Patil, P.S.Kumar and P.C.Naganoor,(2015),? Evolution of nil waste process for utilization of some mine wastes?, Procedia, Earth and Planetary Science, 11, pp 277-285.

Pradip, (2006), ?Processing of Alumina rich Indian iron ore slimes, Intl. J.of Min. Met. and Mate. Engg. 59(5), pp. 551 ? 568

S Roy and A Das,(2008), ?Characterization and Processing of low grade iron ore slimes from the Jiling area of India. Min.Processing and Ex. Meta. Rev., 29,(5), pp. 213 ? 231

G.E.Sridhar, P.C.Naganoor, S.J.Gopalkrishna and M.V.Rudramuniyappa, (2009), ?Beneficiation of iron ore slimes from Sandur mining area, Bellary District, Karnataka? Ind. Min. , 42,(2),pp 161-165.

S.J.G. Krishna, M.R. Patil, C. Rudrappa, B. P..Ravi, P.S. Kumar, M. V.Rudramuniyappa and S. Umesh, (2013), ? Fine particle processing of iron ore slimes from washplant ?, IJERT, 2, (8), pp 207-217

T.V.Vijayakumar, N.Vasumati, S.Subba Rao , S.Prabhakar and G Bhaskar Raju, (2013 ),? Recovery of values from ponds of iron ore washing plants? Ind. Min.,47,(1and2),pp83-92

G.E.Sridhar and P.C.Naganoor, ?Process development for beneficiation of iron ore slimes from Donimalai area?,IJESRT.2015, 4(8),pp796-800.

Y.Tong., J.Zhang and J.Wernham,? The research on application of new technologies in HGMS with horizontal magnetic line?, Proc. XXV IMPC 2010, Brisbane, Australia, pp 1283-1286

M.R.Patil, S.J.G.Krishna, G.E.Sridhar, P.C.Naganoor and B.P.Ravi, (2016), ?Slime processing of an Iron ore wash plant tails- A case study?, IJIR,2(9),pp1717-1720.

B.P.Ravi, G.S.Kumar, B.D.Ananth, M.I.Hussain and MG.Kristappa, (2013), ?Process charcterization of some iron ores from India and Indonesia?, Ind. Min.,47,(1and2),pp 125-134.

Indian Bureau of Mines ??Vision iron and steel?- 2011

Indian Bureau of Mines ?? Monograph of iron ore? 1997