Yunusa Bello M

Email: mybello@fuwukari.edu.ng.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 7 ISSUE: 1

Page No: 431-441

Yunusa Bello M

Email: mybello@fuwukari.edu.ng.com

Yunusa, B. M.1, a, Filli, K. B.2, b, Jiddum, F. A.3, c

1Department of Food Science and Technology, Federal University Wukari, PMB 1020 Wukari, Nigeria,

2,3Department of Food Science and Technology, Modibbo Adama University Yola, PMB 2076, Nigeria

(bkbfilli@yahoo.com, cjiddumfatima@gmail.com)

Yunusa Bello M, Kalep Bulus Filli, Fatima Abdullahi Jiddum, Application of RSM in modelling and Numerical optimisation of proximate composition of instant Extruded kunun-gyada(porridge) from the blend of sorghum-groundnut(2022)Journal of Food Science & Technology 7(1) :431-441

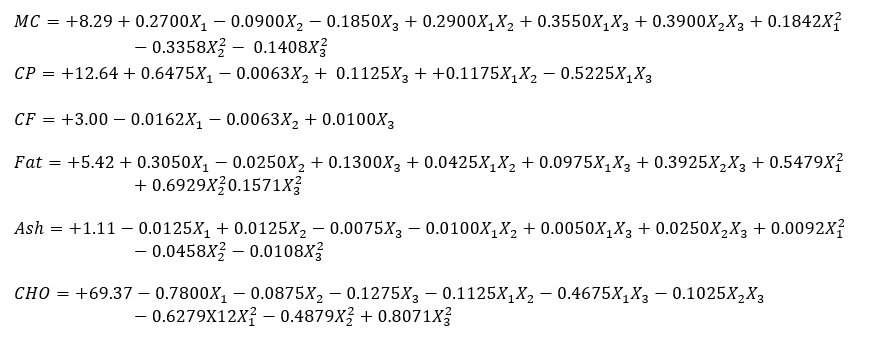

The effect of extrusion parameters on the proximate composition of Kunun-Gyada extrudates was investigated. Fifteen experimental runs were generated using Box-Behnken (RSM) designs and were processed in a single-screw extruder (WSSH-40, Runxiang). The results were subjected to statistical analyses to evaluate for significant (0.01 ≤ p ≤ 0.05) effects between the blends and the extrusion parameters. There was an increase in proximate mean composition of the extrudates, crude protein 11.60 to 13.70%, ash 1.00 to 1.13%, with decrease in both moisture content, crude fiber, crude fat and carbohydrates ranges from 8.60-7.31%, 3.03-2.96%, 6.99-5.40% and 72.32-75.57% respectively. The R2 of all the models were greater than 78% and all were having a non-significant lack-of-fit test. In view of the operability in actual production, the optimal conditions were adjusted as follows: 21.0% FC, 25.0% MC and 110oC BT. Under the adjusted conditions, the responses were 7.89% moisture content, 13.02% crude protein, 3.010% crude fibre, 5.802% fat, Ash 1.070% and 67.268% carbohydrate indicating that the model was adequate for the optimization process. The optimal result could produce kunun-gyada suitable for instant porridge which can potentially be use for industrial projection and sustainable food and nutritional security.

Keyword: Extrusion, optimization, kunun-gyada (porridge), RSM

Kunun-gyada is a porridge from cereals, such as pearl millet, sorghum and maize which is produced by blending it with groundnut milk (Halilu, 2019; Nkama 1995). Sorghum (Sorghum bicolour L.) is a major source of calories in the diets of large number of the most widespread cereals consumed by adults and infants in Sub-Saharan Africa (SSA) and the fifth most important cereal crop in the world, which is used to prepare various dishes including gruel, fermented and unfermented bread, steamed cooked products (dekkere), stiff porridge (tuwo), snack foods, boiled whole or pearled, alcoholic and non- alc1oholic beverages(Yusuf et al., 2017; Kumar et al., 2015). It is an inexpensive source of calories, and also rich in zinc and iron as the second to pearl millet among all cereals and pulses (Dayakar et al., 2018; Ayo and Okaka 1998). Sorghum porridge provides a substantial proportion of the protein and energy for many adults and infants in Nigeria. However, sorghum has a poor protein content and quality, low solubility, interactions with tannin and deficiencies in lysine and tryptophan(Kumar et al., 2015). The sorghum protein quality can be optimised by blending it with other protein-rich legumes particularly with respect to lysine. Groundnut (Arachis hypogeal L) is an important legume in Nigeria, rich in lysine (Halilu, 2019) and has potential to complement sorghum porridge. Kunun-gyada will be commercially valued, if its nutritional value will be improved and make it convenient to consumers as instant product (Halilu et al., 2020). With the advancement in technology for producing nutrient-dense foods, there is a growing need in the consumer industry for new goods that encourage the use of indigenous raw materials. Extrusion cooking is a process that mixes and conveyed a food material through an opening called die to give the desired attributes through increases in temperature, pressure, and shear forces (Filli et al., 2014; Gbenyi et al., 2016). Extrusion cooking is a high temperature short time (HTST) process technique that develops products such as puffed snack and breakfast cereals, has been reported to be the most effective method for enhancing protein and starch digestibility of foods (Filli et al., 2012). Furthermore, extrusion cooking has unique features to inactivate several anti-nutritional compounds that make nutrients unavailable, limiting the grain use as a staple food in the world (Kumar et al., 2015) when compared to other conventional heat processing methods that deteriorates the nutritional quality of food during processing. This study is aimed at the application of RSM to investigate the influence of feed composition, feed moisture and temperature on the proximate composition of the kunun-gyada extrudates.

2.1. Materials

The raw materials used to produce kunun-gyada include: Sorghum, groundnut, tamarind, sugar. These materials were purchased at Jalingo market Taraba State.

Flour preparation was carried out according to the method describe by (Filli et al., 2011)

2.3. Paste Preparation

The groundnuts (Arachis Hypogeae) variety was prepared into paste according to the method describe by (Ularamu et al., 2017).

2.4. Experimental Design

For this analysis, Response Surface Methodology (RSM) with Box-benkhen Design (BBD) was used, which typically has three levels of variables (Danbaba et al., 2015). Feed composition (18-22%), feed moisture content (20-30%) and temperature (90-110oC) were used as extrusion variables, whereas all other parameters were held unchanged. BBD is suitable for sequential experimentation and provides a detailed information for testing lack-of-fit while not using large number of experimental runs. Experimental runs in BBD were estimated by:

Table 1. Experimental levels of the variables

|

Independent Variables |

Coded |

-1 |

0 |

+1 |

|

Feed Composition (%) |

X1 |

18 |

20 |

322 |

|

Moisture Content (%) |

X2 |

20 |

26 |

30 |

|

Temperature (oC) |

X3 |

90 |

100 |

110 |

X1-FC = feed composition (%), X2-MC= Feed Moisture Content (%), X3-BT = Barrel Temperature (oC)

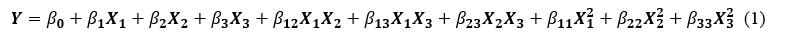

The (RSM) with Box-benkhen Design (BBD) used in this work was produced using Design Expert statistical software (v. 13.0.1.0., Stat-Ease Inc., Minneapolis, MN). The Box-Behnken becomes a full factorial with three extra samples taken at the Centre. Then the response expressed as second-order polynomial equation according to Eq 1.

where X1 = Feed Composition, X2 = Feed Moisture, X3 = Barrel Temperature βo, βv, βiv βij are intercepts, linear, quadratic and interaction regression coefficient terms, respectively.

Table 2. Experimental Design

|

Run |

|

Independent variables in coded form |

Independent variables in natural form |

||||

|

|

|

X1 |

X2 |

X3 |

FC |

MC |

BT |

|

E01 |

|

0 |

0 |

0 |

20 |

26 |

100 |

|

E02 |

|

0 |

0 |

0 |

20 |

26 |

100 |

|

E03 |

|

-1 |

0 |

1 |

18 |

26 |

110 |

|

E04 |

|

-1 |

0 |

-1 |

18 |

26 |

90 |

|

E05 |

|

-1 |

1 |

0 |

18 |

30 |

100 |

|

E06 |

|

1 |

1 |

0 |

22 |

30 |

100 |

|

E07 |

|

1 |

0 |

-1 |

22 |

26 |

90 |

|

E08 |

|

0 |

0 |

0 |

20 |

26 |

100 |

|

E09 |

|

1 |

0 |

1 |

22 |

26 |

110 |

|

E10 |

|

-1 |

-1 |

0 |

18 |

22 |

100 |

|

E11 |

|

0 |

-1 |

1 |

20 |

22 |

110 |

|

E12 |

|

0 |

1 |

-1 |

20 |

30 |

90 |

|

E13 |

|

0 |

-1 |

-1 |

20 |

22 |

90 |

|

E14 |

|

1 |

-1 |

0 |

22 |

22 |

100 |

|

E15 |

|

0 |

1 |

1 |

20 |

30 |

110 |

X1-FC = feed composition (%), X2-MC= Feed Moisture Content (%), X3-BT = Barrel Temperature (oC)

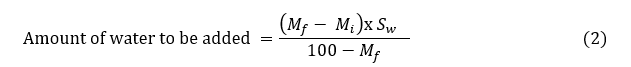

2.5 Blend Formulation and Moisture Adjustment

Fifteen (15) formulations were prepared to contain groundnut paste ranging between 18 - 22% based on the experimental layout in Table 2. Moisture adjustment was carried out according to the method describe by (Gbenyi et al., 2016).

Where Mf = Final moisture content, Mi = Initial moisture content and Sw = Sample weight (g)

2.6. Optimization of the extrusion parameters

The ranges of proximate composition obtained from this study were analysed using Design expert software version 13.0.1.0. (Stat-Ease Inc., Minneapolis) to predict the process conditions that gives the optimum proximate composition. The coefficients of polynomial models, coefficient of determination (R2), adjusted R2 and adequate precision values of the proximate composition of the blends were used to evaluate the model fitness as indicated in Table 2.

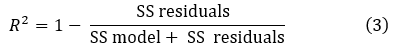

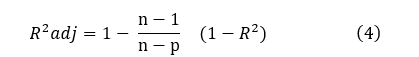

2.7. Validation of Fitted Models

To check if a predicted model can fit, it must provide an adequate approximation to the real system, it is often important to check model adequacy. Unless a model shows adequate fit, proceeding with optimization may lead to misleading results (Danbaba et el. 2016). In this study, numerical validations were conducted on the fitted models. Numerical methods involve the analysis of the coefficient of determination (R2) and adjusted coefficient of determination (R2adj) calculated as:

SS = sum of squares, while n is the number of experiments and p denotes the number of predictors. The fraction of variance in the response that the model fits satisfactorily is defined by an R2 value near to unity and an R2 adj close to R2. The p-value was used to determine the importance of each component. The values of each of the three response variables were recorded in triplicate, and a lack-of-fit test was used to determine the significance of replicate error in contrast to model dependent error. For the analysis, a non-significant lack-of-fit was deemed desirable.

RSM Box-Behnken Design (BBD) was used in this study to investigate the effects feed composition (X1), feed moisture content (X2) and barrel temperature (X3) on the proximate composition, composition of the extruded composite flour from the blends of sorghum-groundnut to optimize these variables for good product quality. Two steps were ensured for a successful application of the experimental design in product development as intended in this study: The first was to identify significant variables from the experimental runs outlined in the experimental design and secondly, optimization by finding the optimum condition settings of the factor variables to meet the design objectives. Tables 3 and 4 show the impacts of the extrusion processing factors studied in this study on the dependent variable’s moisture content, crude protein, crude fat, crude fiber, ash, and carbohydrate. Single-factor coefficients (X1X2, X1X3 and X2X3) reflect the linear influence of a variable, whereas double-factor coefficients (X1X2, X1X3, and X2X3) and coefficients with second-order components (X12, X22, and X32) represent factor interaction and quadratic effects, respectively (Danbaba et al., 2015). A synergetic relationship is shown by a positive regression term, whereas an antagonistic relationship is shown by a negative regression term (Anderson & Whitcomb, 2007).

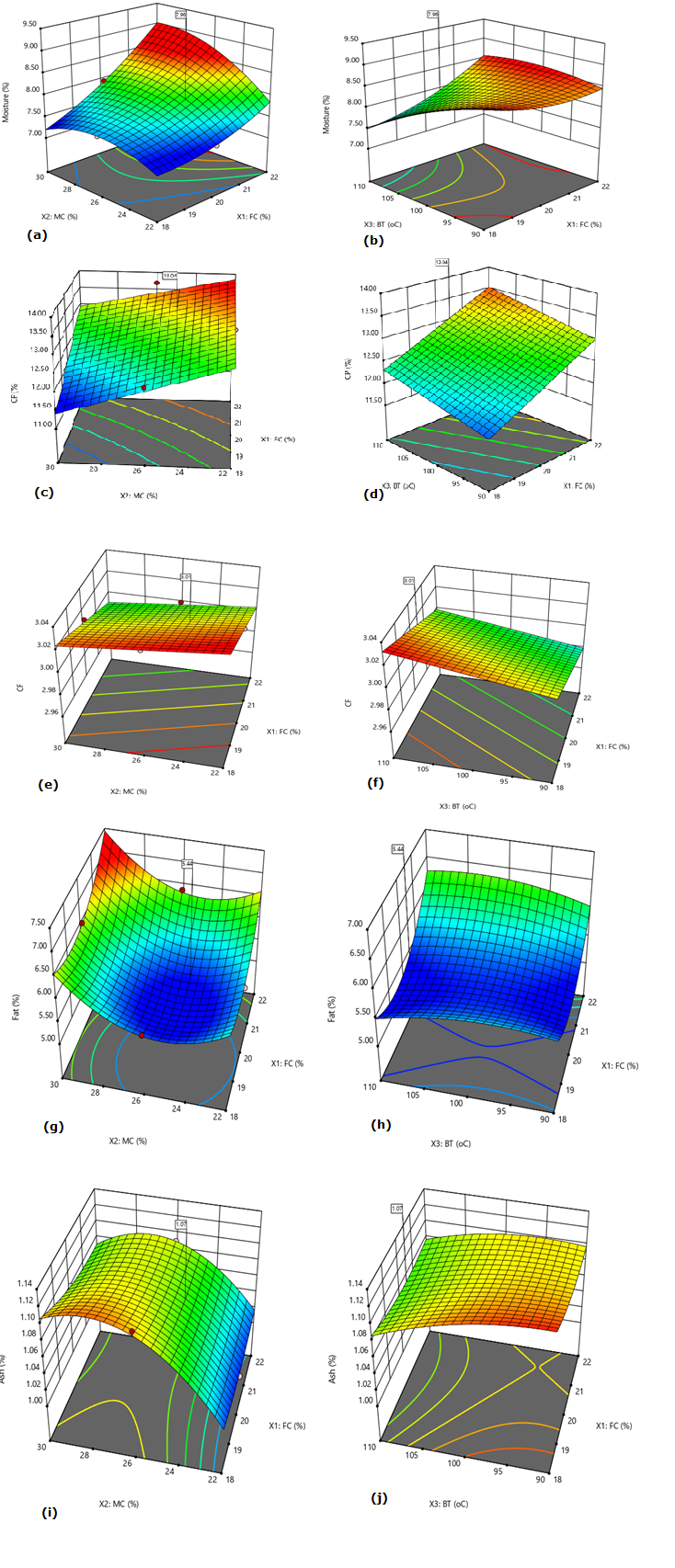

3.1. Moisture content of the extrudates

Sample E07 and E11 were ignored for this analysis to obtain a significant model with non-significant lack of fit. From the coefficient estimate table 4. all the factors’ variables were significant (p ≤ 0.01) influencing moisture content of the extrudates. The interaction between all the parameters and their quadratic effects were all significant (p ≤ 0.05), indicating that the extrusion process reduced the moisture contents of the extrudates. Proximate composition (Table 3) shows the moisture content ranging from 7.31 to 8.60%, the highest value was recorded in sample E04 (18% FC, 26% FMC and 90oC BT) and the least value in sample E11 extruded at 20% FC, 22 MC and 110oC BT. which is within the earlier report by Jiddere & Filli, 2016, that the moisture content of an extruded sorghum malt and bambara groundnut ranges between 3.85 to 8.66% were significantly different (p≥0.01); the findings further shows that the blends extruded at higher temperatures of 100oC above and higher feed moistures of 30% above tend to lose more moisture than the blends extruded at lower temperatures of 100oC below and lower feed moistures content of 20% below, this could be due to constant evaporation rate(Fellows, 2000). Navale et al., (2015) Snacks extruded at a moisture content above 8-12% range, require additional drying to impart desired texture and storage ability. This is in agreement with the finding of (Ularamu et al., 2017), suggesting that while there may be high temperature variations ranging up to 120oC, the moisture content of the extrudates significantly decreases, and remained fairly the same at a temperature below 100oC. Extrudates are discharged from a high pressure and temperature zone to a low pressure and temperature zone, producing expansion and easy evaporation of moisture in the end product (Byaruhanga et al., 2014). The moisture content of the extrudates was impacted negatively by barrel temperature and marginally by feed moisture content in this investigation (Gbenyi et al., 2016). High melt temperature and die pressure, as well as feed composition, have been linked to a reduction in extrudate moisture content. Moisture plays a key role in shelf life, packing, and general acceptance of extrudates, since high moisture products necessitate the use of expensive drying procedures to allow for simple handling and storage. Moisture has a great significance to shelf life, packaging and general acceptability of extrudates as high moisture products demand for the cost operations to dry to allow easy handling and storage. Except for the raw sorghum flour, which has 10.6% moisture level, all the extruded mixes in the above table have low moisture content, which indicates high storability. The findings of this investigation indicated that the goods have a low moisture content and hence have a long shelf life. The results of this study suggested that the products have low moisture content to have an extended shelf life. These has also been reported by Danbaba et al., (2016), that in dry food systems with moisture content between the range of 6-10%, there is a prolong shelf stability, and anything above this range, the stability of the system could be hampered by both microbiological and chemical agents.

3.2. Crude Protein of extrudates

The result as shown in Table 4 shows a significant increase in Crude protein from 11.60 to 13.70%, the highest value was recorded in sample 9 (22% FC, 26% FMC and 110oC BT) and the least value in sample E04 extruded at 18% FC, 26 MC and 90oC BT. It is also clear from these results that the increase in crude protein depend mainly on the feed compositions (p≤0.01), slight increase was also observed due to an interaction between barrel temperature and moisture content significant (p≤0.05) as shown on figure c & d, these could be due extrusion temperature inactivating anti-nutritional factors which are known to form reversible or irreversible complexes with proteins, leading to the reduction of amino acid availability, as well as affecting the protein digestibility(Soetan & Oyewole, 2009),

Table 3. Effects of feed composition, moisture content, and barrel temperature on proximate composition of the extrudates

|

Run |

Independent variables in coded form |

Independent variables in natural form |

Proximate composition (%) |

|||||||||

|

|

X1 |

X2 |

X3 |

FC |

FMC |

BT |

MC |

CP |

CF |

Fat |

Ash |

CHO |

|

E01 |

0 |

0 |

0 |

20 |

26 |

100 |

8.30 |

12.88 |

3.02 |

5.45 |

1.11 |

69.24 |

|

E02 |

0 |

0 |

0 |

20 |

26 |

100 |

8.31 |

12.85 |

3.01 |

5.40 |

1.11 |

69.38 |

|

E03 |

-1 |

0 |

1 |

18 |

26 |

110 |

7.52 |

12.21 |

3.03 |

5.56 |

1.11 |

70.57 |

|

E04 |

-1 |

0 |

-1 |

18 |

26 |

90 |

8.60 |

11.60 |

3.00 |

5.42 |

1.13 |

70.16 |

|

E05 |

-1 |

1 |

0 |

18 |

30 |

100 |

7.47 |

11.83 |

3.01 |

6.24 |

1.10 |

69.04 |

|

E06 |

1 |

1 |

0 |

22 |

30 |

100 |

8.59 |

13.16 |

2.96 |

6.91 |

1.06 |

67.32 |

|

E07 |

1 |

0 |

-1 |

22 |

26 |

90 |

7.50 |

13.10 |

2.98 |

5.86 |

1.09 |

69.47 |

|

E08 |

0 |

0 |

0 |

20 |

26 |

100 |

8.25 |

12.75 |

3.01 |

5.40 |

1.10 |

69.50 |

|

E09 |

1 |

0 |

1 |

22 |

26 |

110 |

7.81 |

13.70 |

3.00 |

6.39 |

1.09 |

68.01 |

|

E10 |

-1 |

-1 |

0 |

18 |

22 |

100 |

8.26 |

12.18 |

3.02 |

6.49 |

1.06 |

68.97 |

|

E11 |

0 |

-1 |

1 |

20 |

22 |

110 |

7.31 |

13.05 |

3.02 |

5.62 |

1.00 |

69.90 |

|

E12 |

0 |

1 |

-1 |

20 |

30 |

90 |

7.53 |

13.14 |

3.00 |

5.50 |

1.05 |

69.69 |

|

E13 |

0 |

-1 |

-1 |

20 |

22 |

90 |

8.46 |

12.16 |

3.00 |

6.22 |

1.07 |

69.68 |

|

E14 |

1 |

-1 |

0 |

22 |

22 |

100 |

8.22 |

13.04 |

2.99 |

6.99 |

1.06 |

67.70 |

|

E15 |

0 |

1 |

1 |

20 |

30 |

110 |

7.94 |

11.94 |

3.01 |

6.47 |

1.08 |

69.50 |

X1-FC = feed composition (%), X2-MC= Feed Moisture Content (%), X3-BT = Barrel Temperature (oC), MC=Moisture Content, Protein (%), CF = Crude Fibre (%), CHO = Carbohydrate, RG = raw groundnut, RS = raw sorghum.

since anti-nutritional factors are heat labile (Ajibola & Olapade, 2021), the positive effect of barrel temperature could be due to the inactivation of the anti-nutritional factors that leads to an increase in the crude protein percentage. This follows a similar phenomenon observed by Gbenyi et al., (2016) that the increased in Bambara groundnut during extrusion leads to an increase in the crude protein of the final product. A similar study was also carried out by Filli et al., (2011) that protein for the ‘fura’ extrudates increases from 11.23 to 16.76% from blends of pearl millet with cowpea flour after extrusion; hence concluded that, the crude protein content was not affected by extrusion temperature and moisture content. A systematic review by Grasso, (2020) examined a number of studies exploring the that an increase in a defatted groundnut during extrusion, increases the crude protein content of the product.

3.3. Crude Fibre of extrudates

The crude fibre content of the sorghum-groundnut extrudates ranged from 2.96 – 3.03%, with sample 3 having the lowest under higher feed composition of 22%, higher feed moisture content of 30% and moderate barrel temperature of 100oC. The crude fibre result of 2.13% of the raw groundnut used in this study was found to be within the ranged reported by Pardeshi, (2019) who investigated the proximate composition of different groundnut seed varieties and finds that their crude fibres ranges from 1.69 to 2.32%. From table 4. two extrusion parameters were significant (p≤0.05), indicating that an increase in extrusion temperature with a decrease in feed composition favour fibre recovery.

Table 4. coefficient estimate for proximate composition of the extrudates

|

Source |

MC |

CP |

CF |

FAT |

ASH |

CHO |

|

coefficient estimate |

coefficient estimate |

coefficient estimate |

coefficient estimate |

coefficient estimate |

coefficient estimate |

|

|

Model |

** |

** |

** |

** |

** |

** |

|

Intercept |

8.29 |

12.64 |

3.004 |

5.42 |

1.11 |

69.37 |

|

linear |

|

|

|

|

|

|

|

X1-FC |

0.27** |

0.6475** |

-0.01623** |

0.305** |

-0.0125** |

-0.78** |

|

X2-MC |

-0.09** |

-0.045 |

-0.00625 |

-0.025 |

0.0125 |

-0.0875 |

|

X3-BT |

-0.185** |

0.1125 |

0.01* |

0.13** |

-0.0075* |

-0.1275 |

|

Interaction |

|

|

|

|

|

|

|

X1X2 |

0.29** |

0.1175 |

|

0.0425 |

-0.01* |

-0.1125 |

|

X1X3 |

0.355** |

-0.0025 |

|

0.0975 |

0.005 |

-0.4675** |

|

X2X3 |

0.39** |

-0.5225** |

|

0.3925** |

0.025* |

-0.1025 |

|

Quadratic |

|

|

|

|

|

|

|

X1² |

0.1842** |

|

|

0.5479** |

0.0092* |

-0.6279** |

|

X2² |

-0.3358** |

|

|

0.6929** |

0.0458** |

-0.4879** |

|

X3² |

-0.1408** |

|

|

-0.1571* |

-0.01083* |

0.8071** |

|

LOF |

NS |

NS |

NS |

NS |

NS |

NS |

|

R² |

0.9984 |

0.8965 |

0.7397 |

0.9910 |

0.9853 |

0.9833 |

|

Adj R² |

0.9937 |

0.8188 |

0.6687 |

0.9747 |

0.9589 |

0.9533 |

|

Adeq P |

40.6513 |

8.8870 |

10.0086 |

21.4022 |

23.2565 |

21.3912 |

X1-FC = feed composition (%), X2-MC= Feed Moisture Content (%), X3-BT = Barrel Temperature (oC), MC=Moisture Content, Protein (%), CF = Crude Fibre (%), CHO = Carbohydrate, *8 = significant (p ≤ 0.01), * = significant (p ≤ 0.05).

This is due to the low percentage level of crude fibre in the raw groundnut (2.13%) and a higher crude fibre content of the raw sorghum. Danbaba et al., (2016) also reported that fibre contents of extruded instant porridge from broken rice fractions blended with cowpea varied between 1.62 to 2.88. During extrusion cooking process, positive effects of the extrusion parameters on the total and soluble fibre has been observed while insoluble dietary fibre decreased as the process parameters changes (Rashid, et al., 2015, Danbaba et al.,2016). These changes may probably be due to disruptions of covalent and non-covalent bonds in the carbohydrate and protein molecules leading to smaller and more soluble molecular fragments (Danbaba et al., 2016). Crude fibre certainly increases the nutritional and functional value of food, but usually alters the rheological properties of the product and hence the quality and sensory properties of the end product; however, functional foods development has a unique opportunity to improve food quality, consumer health and well-being (Gupta & Premavalli, 2012).This is in agreement with this study that an increase in feed composition (groundnut) leads to a slight decrease in crude fibre which is likely to improve the expected rheology of the final product (Kunun-gyada).

3.4. Crude Lipids of extrudates

Table 4 shows that all parameters and were significant (p≤0.05), excluding moisture content and its interaction with feed composition which were not significant (p≤0.05). Crude lipid content ranges from 5.39 to 6.99% (table 3). higher increase in feed composition (groundnut), which could be because groundnut is an oil seed crop, though the value is not as high as 29.38% that was discovered in the raw groundnut on table 3. The interaction effects between moisture content with barrel temperature was significant (p≤0.05) (table 4). Crude oil from the groundnut cell membranes is release and reabsorbed by the sorghum flour which was blended with groundnut to form starch-lipid complex during extrusion cooking in the presence of high temperature and high moisture content(Taraj et al., 2019). This could be the result of the Maillard reaction and the formation lipid-starch complexes during extrusion. This hypothesis was supported by De Pilli et al. (2012) who found that starch-lipid complexes occurred under various extrusion conditions, and the formation of the complex was significantly influenced by barrel temperature and moisture content, this is also in line with Moreira et al., (1997) who noted that as initial moisture content increases, the final oil content decreases under high temperature in peanut. Similar hypothesis was reported by Tran et al., (2008) that under specific extrusion conditions of high-moisture and high-temperature which increases potential interactions with the side chains, lipid–starch could be formed; free fatty acids and polar lipids are especially reactive in these situations with a large extent of amylose–lipid complexes formation.

3.5. Ash content of the extrudates

All the parameters, their interaction, and their increase (quadratic) were significant (p≤0.05), except for the interaction between feed composition with barrel temperature. Ash content occurred through the many chemicals and structural transformations such as starch gelatinization complex formation between amylose and lipids during the extrusion process. Table 3 shows the Ash content ranges from 1.00 to 1.13%, which is within the same range with the findings of Filli et al., (2011) that the ash content for the ‘fura’ extrudates from the blends of pearl millet with cowpea flour after extrusion showed that it remained within a narrow range of 1.67 to 1.98%. Similar finding supporting these results observed low ash contents were reported by (Abioye et al., 2011; Adunni & Olaposi, 2010; Shogren et al., 2006; Obatolu 2002). This could be explained probably because the ash content groundnut paste (4.30%) reported on table 3, has more amount of ash content when compared with sorghum flour (1.27%) but groundnut paste is having an extremely low 18-22% in the formulation blends of 100%. At a lower feed composition and a mid-feed moisture content, a higher Ash content value was obtained. The highest value was recorded in sample E05 (18% FC, 30% MC and 100oC BT) and the least value in sample E11 extruded at 20% FC, 22 MC and 110oC BT). Barrel temperature (Tadesse et al., 2019)and other extrusion parameters did not substantially affect the ash content (Wang, 2018).

3.6. Carbohydrate content of the extrudates

The highest and least values of carbohydrate were recorded in samples E03 and E09 representing extrusion conditions 110oC barrel temperature, 26% feed moisture; and 18% feed composition and 110oC barrel temperature, and 26% feed moisture and 22% feed composition. The result as shown in Table 3. shows a slight increase in Carbohydrate from 67.32 to 70.57%, a similar findings was reported by Filli et al., (2011) that the values for the carbohydrates remained relatively within a narrow range of 74.12 to 77.34%, however, the carbohydrate level relatively remained higher than the findings of this study, as expected cowpea is equally high in carbohydrates. Table 4 shows that feed composition is significant (p≤0.05), It is also clear from these results that the increase in crude carbohydrate depends on the decrease in feed compositions with moderate amount of moisture content and temperature (quadratic effects). Similar finding supporting these results were reported (Tadesse et al., 2019; Abioye et al., 2011; Adunni & Olaposi, 2010; Shogren et al., 2006) that sorghum contains high composition of carbohydrates ranging from 65-75% and during extrusion at high temperature, starch undergo both structural and chemical transformations and complex formation with other components resulting in decreased level in the final product. During extrusion, water is absorbed and bound to the starch molecule with a resulting change in the starch granule structure. A study (Ding et al., 2005) reported that the degree of gelatinization decreases with increasing feed moisture, similar to the results found in this study as shown, but under minimal moisture level and high temperature in extrusion cooking, non-enzymatic browning reaction between molecules of protein and reducing sugar from starch gelatinization resulting in decreased Carbohydrate (Danbaba et al., 2018). Gelatinization is the conversion of raw starch to a cooked starch under the effect of water and heat, is one of the important effects that extrusion has on the starch component of foods. Extrusion cooking causes swelling and rupture of the granules, modification of the crystalline spectra, increase in cold water solubility, reduction in viscosity of the starch and (partial to complete) release of amylose and amylopectin; when extruded at low moisture content, starch granules are partially transformed through the application of heat (loss of crystalline structure) and shear (granularfragmentation), leading to formation of a homogeneous phase called a starch melt or ‘gelatinization(Tran et al., 2008).

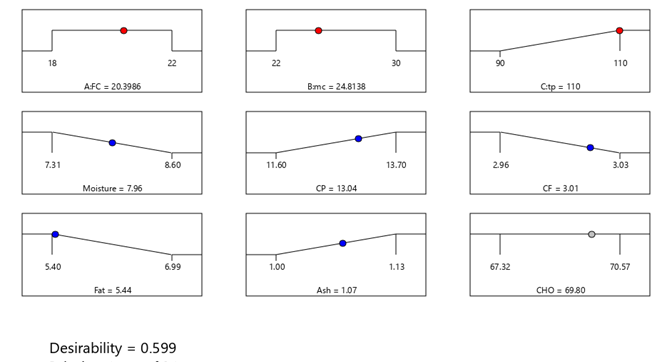

3.6. Numerical Optimization

To obtain optimal numerical values of the response, the desired targets were specified for all parameters. The optimum conditions for factor variables and the predicted values of the responses were also presented as follows: FC was set at an intermediate value of 20.40%, MC value of 24.81% and high BT of 110oC. The predicted response was given by Design expert software version 11.1.2 (Stat-Ease Inc., Minneapolis) under the above conditions was chosen with respect to the lower value of moisture content (7.96%), higher value of crude protein (13.042), higher crude fibre (3.013%), low fat (5.441%), Ash (1.073%) and carbohydrate (69.80%) at an overall desirability of 0.599(approx. 60%). In view of the operability in actual production, the optimal conditions can be adjusted as follows: was set at an intermediate value of 21.0% FC, 25.0% MC and 110oC BT.

Response Surface Methodology was successfully applied to optimize extruded instant kunun-gyada from the blend of sorghum and groundnut, using a single extruder. It was demonstrated that, blends of sorghum and groundnut can be used to produce instant kunun-gyada through suitable selection of processing conditions and higher composition of the ingredient blend by having RSM as a tool. The feed composition and moisture content are the most significant factors that influences the proximate composition of the final product. Modelling of experimental data in this study allowed for the generation of useful equations for general use, to predict different factor combination which was used to produce a good quality porridge. Adopting Extrusion technology to produce instant Kunun-gyada is a welcome idea in meeting up with the SDG’s goal 1.2 which could be considered as a sustainable alternative with acceptable nutritional profile that could be used to mitigate protein energy malnutrition (PEM).

Figure 2. Effect of (a) feed composition(X1) and moisture content (X2), (b) feed composition(X1) and barrel temperature(X3) on Moisture Content, (c) feed composition(X1) and moisture content (X2), (d) feed composition(X1) and barrel temperature(X3) on Crude protein, (e) feed composition(X1) and moisture content (X2), (f) feed composition(X1) and barrel temperature(X3) on Crude fibre, (g) feed composition(X1) and moisture content (X2), (h) feed composition(X1) and barrel temperature(X3) on Fat, (i) feed composition(X1) and moisture content (X2), (j) feed composition(X1) and barrel temperature(X3) on Ash and (k) feed composition(X1) and moisture content (X2), (j) feed composition(X1) and barrel temperature(X3) on Carbohydrates

Ayo, J.A., Okaka, J.C. 1998. "Interaction Effect of Candaba Farinose Extract and pH Levels on some Physiological Properties of Kunun-Zaki", Proceedings of the 22nd annual Conference of the Nigerian Institute of Food Science and Technology

Ajibola, G. O., & Olapade, A. A. (2021). Chemical Composition , Anti-Nutritional Factors and Pasting Properties of Cassava-African Yam Bean Flour Blends for Noodle Preparation. International Journal of Food Studies, 10(February), 1-13.

View ArticleByaruhanga, Y. B., Kassozi, V., Wafoyo, R., Mugoya, C., & Masiga, C. (2014). Properties of Extrudates From Sorghum Varieties. African Crop Science Journal, 22(4), 829-836.

Danbaba, N., Nkama, I., & Badau, M. H. (2016). Application of Response Surface Methodology (RSM) for the Production and Optimization of Extruded Instant Porridge from Broken Rice Fractions Blended with Cowpea. International Journal of Nutrition and Food Sciences, 5(2), 105.

View ArticleDanbaba, N., Nkama, I., Badau, M., & Idakwo, P. Y. (2018). Influence Of Extrusion Conditions On Nutritional Composition Of Rice-Bambara Groundnut Complimentary Foods. Arid Zone Journal of Engineering, Technology and Environment, 14(4), 559-582.

Dayakar, R. B., Suneetha, A., Srenuja, D., & Kiranmai, E. (2018). Standardization of sorghum based extruded snacks by using hot extrusion technology. Journal of Pharmacognosy and Phytochemistry, 7(4), 1356-1361.

Fellows, P. (2000). FOOD PROCESSING.

Filli, K. B., Nkama, I., Jideani, V. A., & Abubakar, U. M. (2011). Application of response surface methodology for the study of composition of extruded millet-cowpea mixtures for the manufacture of fura : A Nigerian food. African Journal of Food Science, 5(17), 884-896.

View ArticleFilli, K. B., Nkama, I., Jideani, V. A., & Ibok, I. U. (2012). System Parameters and Product Properties Responses During Extrusion of Fura from Millet-Soybean Mixtures. Nigerian Food Journal, 30(1), 82-100. 30017-5

View ArticleFilli, K. bulus, Jideani, afam i. o., & Jideani, victoria a. (2014). Extrusion Bolsters Food Security in Africa.

G. Jiddere, A., & Filli, K. B. (2016). Physicochemical properties of Sorghum malt and Bambara Groundnut Based extrudates. J. Food Sci. Techol. Nepal, 9, 55-65.

View ArticleGbenyi, D. I., Nkama, I., & Badau, M. (2016). Modeling Mineral Profile of Extruded Sorghum Bambara Groundnut Breakfast Modeling Mineral Profile of Extruded Sorghum Bambara Groundnut Breakfast Cereals. British Journal of Applied Science & Technology, 17(4), 1-14.

View ArticleGbenyi, D. I., Nkama, I., & Badau, M. H. (2016). Modeling Mineral Profile of Extruded Sorghum Bambara Groundnut Breakfast Cereals. British Journal of Applied Science & Technology, 17(4), 1-14.

View ArticleGrasso, S. (2020). Trends in Food Science & Technology Extruded snacks from industrial by-products : A review. Trends in Food Science & Technology, 99(November 2019), 284-294.

View ArticleGupta, P., & Premavalli, K. S. (2012). Development of radish fibre based snack by response surface methodology (RSM. Journal of Food Science and Technology, 49(1), 58-65. PMid:23572826

View Article PubMed/NCBIHalilu, M. (2019). Production Of A Nutritionally-Improved And Shelf-Stable Ready-To-Consume Kunun Gyada Powder Made From Blends of Rice, Groundnut, Sesame Seed And Germinated Soybean.

Halilu, M., Ghazali, H. M., & Yunusa, M. B. (2020). Effect of germination time on proximate composition , amino butyric acid accumulation and trypsin inhibitor activity of soybean (Glycine max L . Merr .). Journal of the Saudi Society for Food and Nutrition (JSSFN) Effect, 13(1), 86-95.

Kumar, T. V. A., Samuel, D. V. K., Jha, S. K., & Sinha, J. P. (2015). Twin Screw Extrusion of Sorghum and Soya Blends : A Response Surface Analysis. Journal of Agric Science Technology, 17, 649-662.

Moreira, R. G., Sun, X., & Chen, Y. (1997). Factors affecting oil uptake in tortilla chips in deep-fat frying. Journal of Food Engineering, 31(4), 485-498. 00088-X

View ArticlePardeshi, S. (2019). Assessment of Proximate Composition of Groundnut Seeds and Characterisation of their Extracted Oils from different Varieties Grown in India. International Research Journal of Engineering and Technology, 6(8), 854-862.

Tadesse, S. A., Beri, G. B., & Abera, S. (2019). Cogent Food & Agriculture Chemical and sensory quality of sorghum-based extruded product supplemented with defatted soy meal flour Chemical and sensory quality of sorghum-based extruded product supplemented with defatted soy meal flour. Cogent Food & Agriculture, 5(1).

View ArticleTaraj, K., Malollari, I., Ciko, L., Llupa, J., Ylli, A., Ylli, F., & Andoni, A. (2019). Water Distillation Extraction of Essential Oil from Sideritis Raeseri Herb. Environmental Processes, 6(4), 1051-1058.

View ArticleTran, Q. D., Hendriks, W. H., & Poel, A. F. B. Van Der. (2008). Effects of extrusion processing on nutrients in dry pet food. Journal of the Science of Food and Agriculture, 88(March), 1487-1493.

View ArticleUlaramu, J. J., Maina, J. F., Ta'awu, K.G., A., & Nwankwo, R. N. (2017). Production and Nutritional Evaluation of Instantized Kunun Gyada , a Traditional Nigerian Beverage from Malted Sorghum ( Sorghum bicolor ) and Roasted Groundnut ( Arachis hypogeae ) Paste by Extrusion Cooking . Journal of Environmental Science, Toxicology and Food Technology, 11(4), 32-37.

View ArticleWang, S. (2018). Effect of Extrusion Temperature And Moisture On Physical, Functional And Nutritional Properties of Kabuli Chickpea, Sorghum, Maize and their Blends.

Yusuf, M., Halilu, M., Umar, I., & Filli, K. B. (2017). Effect of Barrel temperature Feed composition and Feed moisture content on some Functional Properties of Dakuwa extrudates from Blends of Sorghum (( Sorghum bicolour L ) Groundnut ( Arachis hypogeal L ) and Tiger nut ( Cyperus esculentus ). African Journal of Food Science and Technology, 8(9), 150-161.

View Article