Nain Caroline Waingeh

Email: nainkain@yahoo.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 4 ISSUE: 9

Page No: 946-955

Nain Caroline Waingeh

Email: nainkain@yahoo.com

Nain Caroline Waingeh1*, Njoya Moyouwou Amadou1, Mahbou Peter Yunenui1, Nde Sylvanus Nche1, Imele Helene1, Nambangia Justin Okolle 2, Lendzemo Wirnkar Venasius1, Tata Ngome Precillia2, Woin Noe2

1 Institute of Agricultural Research for Development (IRAD) Bambui Centre, P.O. Box 51 Bamenda, Cameroon

2 Institute of Agricultural Research for Development (IRAD) Nkolbisson, P.O. Box 2123 Yaoundé, Cameroon

Rosen Chochkov(rosen4o4kov@abv.bg)

Ioanna Kosma(ikosma@cc.uoi.gr)

Jie Ding(dingjiedream@163.com)

Maria Brigida Dos Santos Scholz(mbscholz@iapar.br)

Nain Caroline Waingeh, Njoya Moyouwou Amadou, Mahbou Peter Yunenui, Nde Sylvanus Nche, Imele Helene, Nambangia Justin Okolle, Lendzemo Wirnkar Venasius, Tata Ngome Precillia, Woin Noe, Assessing the processing attributes of some potato (Solanum tuberosum L) varieties grown in the North West Region of Cameroon(2019) Journal of Food Science & Technology 4(9)p:946-955

Seven potato (Solanum tuberosum L.) varieties: Cipira, Jacob 2005, Mumbi, Banso, Belo, Mondial and Dosa grown in the North West Region of Cameroon and harvested at full maturity in January 2018 were analysed for processing attributes. These attributes were; external parameters (tuber size, shape, eye-depth, number of eyes), internal parameters (Dry matter (total solids), Moisture content, soluble solids, pH, titratable acidity) and Sensory properties (colour, texture, flavour and overall acceptability) of boiled tubers as well as potato fries from these varieties. Apart from Cipira, Jacob 2005 and Mondial with shallow eyes, all the other varieties had deep eyes. Cipira, Mumbi, Banso and Belo varieties registered a high dry matter content (>20 %) with that of Cipira being the highest (26.45%). An appraisal of the technological quality indicated that Cipira, Mumbi, Banso and Belo varieties had best characteristics for frying, mashing and roasting, with Cipira and Mumbi ideal for fries with respect to size and Banso and Belo ideal for crisps. On the other hand, Dosa and Jacob were better suited for mashing and roasting while tubers of Mondial were shown to be suitable for boiling and more appropriate to be consumed in the form of salads. The best overall acceptability of potato fries and boiled potatoes was recorded for products made with Cipira, Banso and Mumbi varieties. Each of these varieties is therefore of importance as its cultivation can target a particular processing technique.

Keywords: External Parameters, Internal Parameters, Potato, Sensory Evaluation, Technological quality.

After wheat, rice and maize, potato is the most important food crop in the world [1]. It contributes to almost 50% of the total tuber and root crop production. Potato has a good food value as compared to other staple food crops as it is rich in carbohydrates and also contains proteins, minerals like calcium, potassium and vitamins like vitamin C. Compared to other roots and tubers and also many cereals, potato tubers have a high protein to carbohydrates ratio with a high nutritional value of the protein [2]. The growth in potato production area has rapidly overtaken all other food crops in developing countries and potato has become a fundamental element in the food security for millions of people across Africa [3].

Potato, though not a traditional staple food in Cameroon, is becoming an important agricultural commodity in the country. It is grown in the highland zones of six regions: North West, West, Adamawa, South West, Far North and Littoral with the Western Highlands (North West and West regions) accounting for 80% of the national production [4]. The crop has now assumed a cash-food crop status with an annual tonnage of over 250,000 tonnes, grown on over 70000 hectares in Cameroon [5] and is one of the main sources of revenue to farmers of these regions.

Potato, like other root and tuber crops is bulky and perishable [6]. With population doubling every 25 years and continuous yearly increase in urbanisation, feeding habits are changing in favour of easy-to-prepare foods [7]. Processing has potential for enabling potatoes achieve an industriallevel status similar to that of maize and wheat. This would contribute to increase its shelf life, improve nutrition, create more employment, and enhance the income for potato farmers. However, the aptness of potatoes for processing is dependent on the tuber quality which takes into consideration both internal and external parameters [8]. The external parameters include: the appearance (size, shape and eye-depth) and defects on the skin, which influence wastage during processing while internal parameters include: dry matter, reducing sugar content, and discoloration in cut tubers and processed tubers. These parameters will greatly influence the profitability and consumer appeal of processed products. Other factors that may interfere in a negative and/or indirect way on the technological quality of tubers are pulp pH, total acidity, and starch content. The pH index determines deterioration potential by fermentation and the activity of enzymes whereas the starch which constitutes the greater part of the dry matter has an influence on the texture of the processed product. Previous findings showed that technological parameters of potato are influenced by genotype or cultivar [9].

The potato varieties in Cameroon can be classified into 3 main categories: the improved varieties, the imported (European) varieties and the local varieties [10]. The Institute of Agricultural Research for development (IRAD) in collaboration with the International Potato Centre (CIP) released several improved potato varieties, two of which (Cipira and Tubira) have been widely adopted by the Cameroonian public for their high yields and resistance to late blight [11, 12] adding to local varieties and imported varieties that are cultivated by farmers.

The objective of this study was therefore to evaluate the suitability of potato varieties grown in Cameroon to processing techniques, in order to identify their best forms of transformation, sales and consumption.

2.1. Study area and Sample collection

The Potato varieties used for this study were obtained from farmers of the Santa Municipality (05°51.382' N; 010°10.500' E) in Mezam Division, North West Region of Cameroon. The Santa locality has an average annual rainfall of 2135 mm and an average temperature of 18.8 °C with penevoluted ferralitic and Aliatic soils [13]. Agriculture is one of the important economic activities of this locality with potatoes, cabbage, carrot, green beans, tomatoes and green spices being common agricultural produce of the municipality.

The potato tubers harvested at full maturity in the month of January 2018 were bought from farmers after they were harvested and transported in bags to the Food Technology and Post-Harvest Laboratory, IRAD Bambui for quality evaluation. Based on the availability of varieties during the research period, a sample of each variety was obtained from two or more farmers. The varieties used for the study are shown in Table 1 below.

Table 1: varieties and number of samples collected

|

No |

Name of variety |

Class of variety |

|

1 |

Cipira |

IRAD Improved |

|

2 |

Jacob 2005 |

IRAD Improved |

|

3 |

Mumbi or Dschang |

Local |

|

4 |

Banso |

Local |

|

5 |

Belo |

Local |

|

6 |

Mondial |

Imported |

|

7 |

Dosa |

Imported |

2.2. Determining the technological quality of potato tubers

The technological quality of potato tubers refer to a number of features (external and internal) determining their suitability for processing [14]. The external parameters include the tuber size, shape, eye-depth and number of eyes while the internal parameters include the Dry matter (total solids), Moisture content, soluble solids, pH, titratable acidity, flesh colour and time taken for darkening of cut tuber (enzymatic browning).

2.3. External parameters: Tuber size, Shape and Presence of eyes

Twenty potato tubers per variety were randomly selected from the lot obtained from each farmer.

2.4. Internal parameters

The internal parameters of potato tubers take into consideration the chemical composition and features of the potato flesh. The following parameters were evaluated within this study.

2.5. Dry matter and moisture content

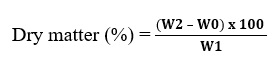

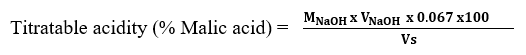

Dry matter and moisture content were evaluated according to the standard Association of Official Analytical Chemists methods [16]: 10 potato tubers per variety were randomly selected from the lot, washed with potable water, finely peeled and sliced into small pieces. The dry matter and moisture content were determined for each sample in duplicate as follows:

Moisture content (%) = 100 – Dry matter

2.6. Soluble solids (°Brix)

The juice extracted from the pulp of grated potato tubers was used for the determination of soluble solids. Two droplets of juice at 20 °C were placed on the prism of an Eclipse refractometer and the value read on the scale of the instrument and recorded. Two replicates per sample were performed.

2.7. Pulp pH and Titratable acidity

As described by Feltran et al. [9]: 50 g of potato flesh was ground with 100 mL of distilled water. The pH value was measured by using a digital pH-meter (HANNA pHep). Titratable acidity on the other hand was determined by titrating the filtrate obtained from the ground sample (50 g of potato flesh (Vs) in 100 mL distilled water), with a 0.1 M NaOH solution using phenolphthalein as end point indicator. The titration was done in duplicate and the average titre (VNaOH) used in the calculation of titratable acidity expressed as % malic acid.

2.8. Flesh colour and Rate of enzymatic browning

Ten tubers from each variety were cut into two halves each and observations were ensured by 5 researchers. The tuber flesh colour was recorded and the enzymatic browning rate was measured as the time taken by the sliced potato to have a prominent colour change.

2.9. Sensory evaluation of processed products

Peeling, frying and boiling are the basic steps of potato cookery in Cameroon and therefore any evaluation at this stages can give an excellent perception of what consumers’ preference would be of the final product. The sensory evaluation therefore focused on boiled potatoes and potato fries.

2.10. Preparation of products for sensory evaluation

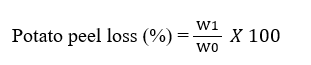

Each potato variety was washed several times with potable water then the quantity to be used weighed (W0). It was then finely peeled using a potato peeler or a sharp knife and the weight (W1) of the peels recorded in order to determine the losses incurred at this stage of processing.

Using the formula below, the Peel losses for each potato variety was evaluated:

W0: Weight of unpeeled potatoes W1: Weight of peels

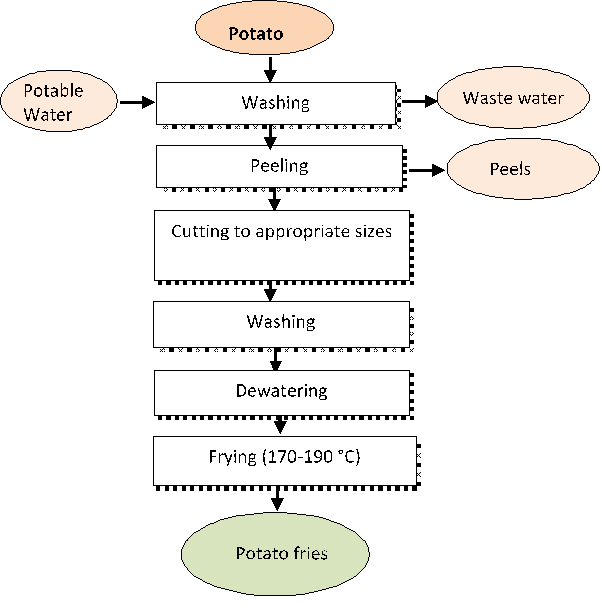

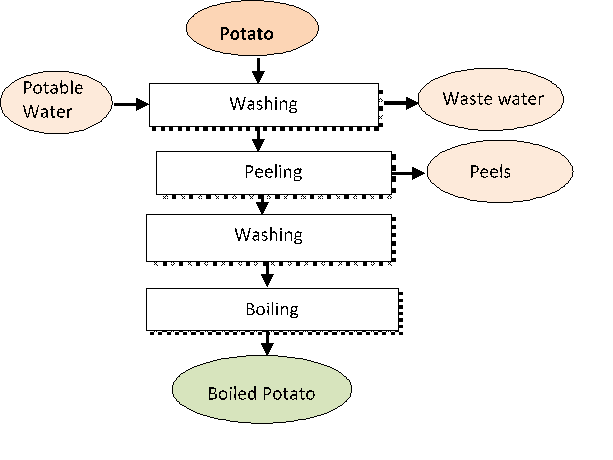

The products for evaluation were then processed following the process diagrams below.

2.11. Potato fries

After potatoes were peeled and washed, the potato tubers for each variety were sliced into long strips and fried without salting for 10-15 minutes at 170-190 °C using an electrical deep fryer.

Figure 1: Processing steps for potato fries preparation

2.12. Boiled potatoes

The peeled potatoes were placed in a stainless steel pot containing boiling unsalted tap water and cooked until ready (considered ready when fork could penetrate).

Figure 2: Processing steps for boiled potatoes

2.13. Sensory evaluation session

The sensory evaluation of fried potato and boiled potato samples were done using a 9-point hedonic scale with categories from like extremely (9) to dislike extremely (1) as shown below:

|

Acceptability |

Quality description |

score |

|

Unacceptable |

Extremely poor |

1 |

|

Very poor |

2 |

|

|

Barely acceptable |

poor |

3 |

|

Below fair/above poor |

4 |

|

|

Fair |

5 |

|

|

Acceptable |

Below good/above fair |

6 |

|

Good |

7 |

|

|

Very good |

8 |

|

|

Highly acceptable |

Extremely good |

9 |

The sensory attributes evaluated were colour, texture, flavour and overall acceptability. The evaluation was carried out by a panel of 15 persons made up of researchers and technicians of IRAD Bambui Centre who are regular potato consumers. The panellists aged between 20 and 60 years old, consisted of both male and female. Each sample was separately served to panellists with potable water for rinsing of mouth between samples.

2.14. Statistical analysis

The data obtained for tehnological quality of potato tubers were expressed as Mean ± SD and those from the sensory evaluation by panellists, were subjected to the Analysis of Variance (ANOVA) using the Statgraphics Plus, version 5.0 statistical package. The means obtained were separated using the Fischer Test (P≤0.05).

3.1. External parameters of potato varieties

The results obtained for external parameters are presented on Table 2.With regard to size, Mondial tubers (91.45 mm) were the longest while Jacob 2005 and Dosa which were similar in length (46.74 mm and 47.05 mm respectively), were the shortest. The tubers of Cipira, Mumbi and Dosa recorded the largest mean diameters (>55 mm). The desired tuber size depends on the product envisaged. For industries processing potatoes, tubers larger than 50 mm are ideal for French fries while tubers between 40 to 60 mm are ideal for crisps [8, 17]. Therefore, considering the size of tubers alone, Cipira, Mumbi and Dosa will be ideal for fries while all of the varieties will be good for crisps.

Table 2: Potato tuber size, shape and presence of eyes with respect to variety

|

Variety |

Tuber size |

Tuber shape |

Presence of eyes |

|||

|

Length (mm) |

Diameter (mm) |

Index value |

Shape |

Number of eyes |

Eye-depth |

|

|

Cipira |

62.86±4.43 |

58.65±4.16 |

107.18 |

Round |

9 |

Shallow |

|

Jacob 2005 |

46.74 |

45.95 |

101.72 |

Round |

8 |

Shallow |

|

Mumbi |

61.90±4,24 |

57.53±0.90 |

107.59 |

Round |

11 |

Deep |

|

Banso |

52.97±8.12 |

43.33±5.62 |

122.23 |

Short-Oval |

9 |

Deep |

|

Belo |

57.88±2,02 |

42.28±7.25 |

136.90 |

Oval |

10 |

Deep |

|

Mondial |

91.45 |

45.90 |

199.24 |

Long |

9 |

Shallow |

|

Dosa |

47.05 |

55.40 |

84.93 |

Round |

10 |

Deep |

The shapes of the tubers as per the index value were in line with the physical observations. Round or oval potato tubers are selected for crisps and dehydrated products while oblong or oval varieties will be suitable for fries [14]. Unlike potato tuber size that is influenced by cultural practices, shape and eye-depth are varietal characteristics. Varieties with shallow eyes are mostly preferred for processing as deep eyes result in higher peeling loses [8]. Apart from Cipira, Jacob 2005 and Mondial with shallow eyes, all the other varieties had deep eyes.

3.2. Internal parameters of potato varieties

As shown on Table 3, the varieties analysed showed dry matter values ranging from 15.43 (Mondial) to 26.45 % (Cipira) and percentage moisture ranging from 73.55 to 84.57%. The texture and oiliness of processed potato products is partly determined by dry matter content. A level of potato tuber dry matter content above 20% is best for fries and crisps because it results in higher product yield and profitability, improves crispness of the fried products and prevents excessive fat absorption during frying [8, 15]. The dry matter content of Mondial tubers (15.43) therefore indicates that this variety is not best for fries. Based on the classification [9], Cipira, Mumbi, Banso and Belo varieties with high drymatter (>20) are good for frying, mashing and roasting whereas Dosa and Jacob with intermediate dry matter content (between 18 and 19.9 %) will be preferred for mashing and roasting and Mondial which falls in the group with low dry matter content (<17.9 %) will be more appropriate for salads.

Table 3: Dry matter content, percentage moisture, soluble solids, pH and titratable acidity of potato varieties.

|

Variety |

Dry matter (%) |

Moisture (%) |

soluble solids (°Brix) |

Pulp pH |

Titratable acidity (% malic acid) |

|

|

|

|

|

|

|

|

Cipira |

26.45±1.00 |

73.55±1.00 |

5.25±0.5 |

6.24±0.22 |

0.23±0.07 |

|

Jacob 2005 |

18.86 |

81.14 |

4.50 |

6.24 |

0.25 |

|

Mumbi |

24.89±1.68 |

75.11±1.68 |

5.50±0.87 |

6.30±0.18 |

0.28±0.04 |

|

Banso |

25.27±1.32 |

74.73±1.32 |

5.25±0.25 |

6.45±0.13 |

0.29±0.04 |

|

Belo |

25.63±0.05 |

74.37±0.05 |

5.50±0.00 |

6.49±0.06 |

0.29±0.03 |

|

Mondial |

15.43 |

84.57 |

4.50 |

6.14 |

0.22 |

|

Dosa |

19.42 |

80.58 |

5.00 |

6.36 |

0.25 |

The soluble solids (sugar content) obtained for varieties studied ranged from 4.5 °Brix (Jacob 2005 and Mondial) to 5.5 °Brix (Mumbi and Belo). Mumbi and Belo with the highest values of soluble solutes indicates the presence of more sucrose. The soluble solids recorded for Mondial (4.5 °Brix) in this study, is the same as that from previous findings [18] and similar to 4.88°Brix obtained by other authors [9]. High sugar content increases tuber susceptibility to browning during processing and results in undesired sweet flavour of cooked potatoes [14].

The pulp pH obtained for the varieties ranged from 6.14 to 6.49 with the Belo variety recording the highest pH closely followed by Banso. The pH values recorded in this study were higher than 5.16 to 5.94 recorded from previous study [9]. This indicates that these tubers have a greater probability of undergoing a faster fermentation.

The values of titratable acidity obtained in this study (0.22 to 0.29 %) are higher than 0.15 to 0.19 % obtained by some authors [18] for Agata and Mondial varieties. These authors showed that, greater availability of phosphorus can reduce the amount of organic acids in the tubers. The high acidity recorded in this study could therefore be as a result of low phosphorus fertilisation.

3.3. Flesh colour

The tuber flesh colour and time for browning after exposure to air are presented in table 4.

Table 4: Tuber flesh colour and time taken for browning after exposure to air.

|

Variety |

Flesh colour |

Time of exposure before browning (Minutes) |

|

Cipira |

Cream |

30 - 60 |

|

Jacob 2005 |

Whitish |

< 30 |

|

Mumbi |

Cream |

30 - 60 |

|

Banso |

Cream |

30 - 60 |

|

Belo |

Cream |

> 90 |

|

Mondial |

Cream |

30 - 60 |

|

Dosa |

Cream |

> 90 |

Apart from Jacob 2005 with a white colour, all the other varieties were cream in colour. Upon exposure of cut tubers to air for a period of time, a discoloration of the tubers was observed with the colour turning to brown. This browning reaction is caused by the oxidation of phenolic compounds by the enzyme phenolase [8]. Cut tubers of Belo and Dosa varieties kept longer (> 90 minutes) without any noticeable change in colour whereas in < 30 minutes, Jacob 2005 became discoloured. It was also observed that for some tubers the browning did not occur on the whole surface of the slice but in a ring a few millimetres inside the skin of the potato. Discoloration reflects damage (knocks and bruises) from rough handling during and/or after harvest and this affects the quality of processed products as discolored parts show up as a dark area in the finished product [19].

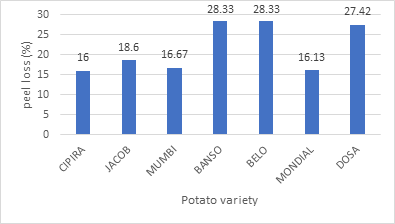

3.4. Potato peel loss

The potato varieties with highest peel losses (28.33%) were Banso and Belo Varieties closely followed by Dosa (27.42%) (Figure 3). These are all varieties with deep eyes, confirming the assertion that deep eyes result in higher peel losses [8]. However, Mumbi also having deep eyes registered a lower loss (16.67) and this could be due to the fact that this variety had a similar number of eyes like Banso, Belo and Dosa but on a larger surface area. The lowest peel loss (16%) was registered for Cipira tubers.

Figure 3: Percentage peel loss per potato Variety

3.5. Sensory properties of Potato fries

Table 5: Sensory scores of potato fries

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptability |

|

Cipira |

7.71±1.06a |

8.14±0.66a |

7.28±0.72a |

8.14±0.36a |

|

Jacob 2005 |

5.71±1.63c |

6.42±1.08b |

6.14±1.29b |

6.42±1.45bc |

|

Mumbi |

7.57±1.82ab |

7.85±0.86a |

7.71±0.46a |

8.28±0.91a |

|

Banso |

8.00±0.78a |

8.14±0.86a |

7.57±0.93a |

8.14±0.86a |

|

Belo |

6.85±0.86b |

6.57±0.93b |

6.42±1.08b |

6.71±0.91bc |

|

Mondial |

7.25±0.44ab |

5.87±1.31b |

5.87±1.50b |

6.12±1.31c |

|

Dosa |

6.87±0.80b |

6.12±0.80b |

6.50±1.03b |

7.00±0.73b |

(a,b, c):Values with the same superscript letter in the same column are not significant different (P>0.05).

Amongst all the potato varieties, the colour of fried potato was significantly (p≤0.05) less appreciated for Jacob 2005. Banso variety registered the best score for colour which was comparable (p>0.05) with scores for Cipira, Mumbi and Mondial.

The texture of fried potato samples were highly appreciated for Cipira, Banso, Mumbi with similar (p>0.05) scores which were significantly (P≤0.05) higher than those of Dosa, Mondial, Jacob 2005 and Belo which were less appreciated. A similar trend to texture appreciation was observed for the appreciation of flavour of potato fries.

Mumbi, Banso and Cipira presented the highest scores in terms of overall acceptability of fried potato samples. Those scores were similar (p>0.05) and significantly (p≤0.05) greater than those of other samples. When fried, Mondial showed the lowest overall acceptability score compared with the other varieties and not significantly (p>0.05) different with scores of Jacob 2005 and Belo.

3.6. Effect of age on the sensory evaluation of potato fries

From Table 6, it can be observed that the age of panellists did not affect (p>0.05) the appreciation of fried Dosa, Mondial, Jacob 2005 and Belo varieties. However, panel members of less than 30 years recorded significantly (p≤0.05) high appreciation for all attributes of Mumbi fries and for the colour of Banso and Cipira fries. The overall acceptability of potato fries was not significantly (p>0.05) affected by the age of the panellists except for Mondial and Mumbi varieties. However, potato fries made from the different varieties all registered acceptable scores by both age groups.

Table 6: Sensory evaluation scores of fried potato with respect to age group (years)

|

|

Sensory attributes |

|||||||

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptabily |

||||

|

≤ 30 |

> 30 |

≤ 30 |

> 30 |

≤ 30 |

> 30 |

≤ 30 |

> 30 |

|

|

Dosa |

6.8±1.0 |

7.0±0.0 |

6.2±0.8 |

6.0±0.9 |

6.2±1.0 |

7.0±0.9 |

7.2±0.8 |

6.66±0.5 |

|

Mondial |

7.4±0.5 |

7.0±0.0 |

5.4±1.4 |

6.66±0.5 |

5.4±1.1 |

6.66±1.9 |

5.6±1.3 |

7.0±0.9* |

|

Mumbi |

8.75±0.5* |

6.0±1.8 |

8.25±0.5* |

7.33±1.0 |

8.0±0.0* |

7.33±0.5 |

9.0±0.0* |

7.33±0.5 |

|

Jacob 2005 |

5.75±1.4 |

5.66±2.1 |

6.75±1.2 |

6.0±0.9 |

5.75±1.6 |

6.66±0.5 |

6.5±1.6 |

6.33±1.4 |

|

Banso |

8.5±0.534* |

7.33±0.5 |

8.25±0.9 |

8.0±0.9 |

7.5±0.9 |

7.66±1.0 |

8.25±0.9 |

8.0±0.9 |

|

Cipira |

8.25±0.9* |

7.0±0.9 |

8.25±0.5 |

8.0±0.9 |

7.25±0.5 |

7.33±1.0 |

8.25±0.5 |

8.0±0.0 |

|

Belo |

7.0±1.1 |

6.66±0.5 |

6.75±0.5 |

6.33±1.4 |

5.75±0.9 |

7.33±0.5 |

6.5±0.9 |

7.0±0.9 |

(*): the value with this symbol the same sensory attribute and for each potato variety is significantly higher (p≤0.05)

3.7. Effect of gender on sensory evaluation of potato fries

The results obtained for potato fries indicated that the male had a significantly low (p≤0.05) appreciation for all sensory attributes of fries from Mumbi variety (Table 7). Appreciation of other fried potato varieties were not much affected by the gender except for the colour of potato fries from Banso variety and the texture of potato fries from Belo variety which were significantly (p≤0.05) highly appreciated by female.

Table 7: Sensory evaluation scores of fried potato with respect to gender

|

|

Sensory attributes |

|||||||

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptabily |

||||

|

Male |

Female |

Male |

Female |

Male |

Female |

Male |

Female |

|

|

Dosa |

7.0±0.00 |

6.8±1.03 |

6.0±0.89 |

6.2±0.78 |

7.0±0.89 |

6.2±1.03 |

6.66±0.51 |

7.2±0.78 |

|

Mondial |

7.0±0.00 |

7.4±0.51 |

6.0±1.54 |

5.8±1.22 |

6.0±2.36 |

5.8±0.78 |

6.0±1.78 |

6.2±1.03 |

|

Mumbi |

5.0±1.15 |

8.6±0.51* |

7.0±1.15 |

8.2±0.42* |

7.0±0.00 |

8.0±0.00* |

7.0±0.00 |

8.8±0.42* |

|

Jacob 2005 |

5.0±2.30 |

6.0±1.33 |

6.6±1.15 |

6.6±1.07 |

7.0±0.00 |

5.8±1.39 |

6.5±1.73 |

6.4±1.42 |

|

Banso |

7.5±0.57 |

8.2±0.78* |

8.5±0.57 |

8.0±0.94 |

8.0±1.15 |

7.4±0.84 |

8.5±0.57 |

8.0±0.94 |

|

Cipira |

6.5±0.57 |

8.2±0.78 |

8.0±1.15 |

8.2±0.42 |

7.0±1.15 |

7.4±0.51 |

8.0±0.00 |

8.2±0.42 |

|

Belo |

6.5±0.57 |

7.0±0.94 |

5.5±0.57 |

7.0±0.66* |

7.0±0.00 |

6.2±1.22 |

7.0±1.15 |

6.6±0.84 |

(*): For the same sensory attribute and for each potato variety, the value with this symbol is significantly higher (p≤0.05).

3.8. Sensory properties of Boiled potatoes

Table 8: Sensory scores of boiled potato

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptability |

|

Cipira |

7.50±0.73a |

6.87±1.31ab |

7.37±1.25a |

7.62±0.88a |

|

Jacob 2005 |

4.50±1.54d |

6.12±1.74b |

5.62±1.36c |

5.87±1.89c |

|

Mumbi |

7.37±1.02ab |

7.00±1.03ab |

6.37±1.25bc |

7.00±1.26ab |

|

Banso |

6.50±1.36bc |

7.00±1.03ab |

6.62±1.25ab |

7.12±1.31ab |

|

Belo |

6.12±1.58c |

7.25±0.44a |

6.50±1.54abc |

7.00±1.26ab |

|

Mondial |

7.00±1.71abc |

6.12±2.15b |

5.62±1.92c |

6.25±1.84bc |

|

Dosa |

6.62±1.45abc |

6.62±0.88ab |

6.62±0.88ab |

6.62±0.88bc |

(a,b,c): Values with the same superscript letter in the same column are not significant different (P>0.05)

From Table 8 , the boiled Cipira variety indicated the highest score with regards to colour and this value was significantly (p≤0.05) different from those of Jacob 2005, Belo and Banso. On the other hand, the boiled tuber colour of Jacob 2005 was less appreciated (p≤0.05) by panellists followed by Belo Variety.

The texture of boiled Belo tubers were significantly more appreciated (p≤0.05) by the panel members compared to the boiled tubers of Jacob 2005 and Mondial varieties. However, apart from the Belo Variety, all other boiled varieties had similar appraisal (p>0.05) in terms of texture.

Mondial and Jacob 2005 obtained the lowest score for flavour of boiled potato which was comparable (p>0.05) to those of Belo and Mumbi. The flavour of Cipira was highly appreciated but at the same level (p>0.05) with that of Dosa, Banso and Belo.

Looking at the overall acceptability of boiled tubers, Cipira registered the highest score which was not significantly (p>0.05) different from those of Banso, Belo and Mumbi. The lowest acceptability was recorded for Jacob 2005 which showed no significant difference (p>0.05) with Mondial and Dosa.

3.9. Effect of age on sensory evaluation of boiled potato

Apart from the flavour of boiled Cipira variety that was more appreciated by panellist above 30 years, age had no effect (p>0.05) on the sensory attributes of all the other boiled potato samples and they also had no effect on the acceptability (Table 9).

Table 9: Sensory evaluation scores of boiled potato with respect to age group

|

|

Sensory attributes |

|||||||

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptabily |

||||

|

≤ 30 |

> 30 |

≤ 30 |

> 30 |

≤ 30 |

> 30 |

≤ 30 |

> 30 |

|

|

Dosa |

7.0±2.0 |

6.25±0.5 |

7.0±0.8 |

6.25±0.9 |

7.0±0.8 |

6.25±0.9 |

7.0±0.8 |

6.25±0.9 |

|

Mondial |

7.0±1.9 |

7.0±1.7 |

6.0±2.5 |

6.25±1.9 |

5.5±2.4 |

5.75±1.4 |

6.25±2.1 |

6.25±1.8 |

|

Mumbi |

7.25±1.2 |

7.5±0.9 |

7.0±0.8 |

7.0±1.3 |

6.5±0.9 |

6.25±1.6 |

7.5±1.2 |

6.5±1.2 |

|

Jacob 2005 |

4.0±1.7 |

5.0±1.3 |

6.25±1.6 |

6.0±2.0 |

5.5±1.2 |

5.75±1.6 |

5.75±1.9 |

6.0±2.0 |

|

Banso |

6.5±1.2 |

6.5±1.6 |

7.0±1.3 |

7.0±0.8 |

7.0±1.3 |

6.25±0.8 |

7.25±0.9 |

7.0±1.7 |

|

Cipira |

7.75±0.5 |

7.25±0.9 |

6.25±1.6 |

7.5±0.5 |

6.75±1.6 |

8.0±0.0* |

7.25±0.9 |

8.0±0.8 |

|

Belo |

6.25±1.4 |

6.0±1.8 |

7.25±0.5 |

7.25±0.5 |

6.5±0.53 |

6.5±2.2 |

7.25±0.5 |

6.75±1.8 |

(*): the value with this symbol for the same sensory attribute and for each potato variety, is significantly higher (p≤0.05)

3.10. Effect of gender on sensory evaluation of boiled potato

The sensory scores for boiled potatoes showed no significant difference in the overall acceptability with respect to gender except for Dosa that registered a better acceptability score by the female. The female also better appreciated the flavour of the boiled Dosa variety and the colour of the boiled Cipira; apart from these, the sensory attributes were not affected by the gender for the other varieties.

Table 10: Sensory evaluation scores of boiled potato with respect to gender

|

|

Sensory attributes |

|||||||

|

Potato variety |

Colour |

Texture |

Flavour |

Overall acceptability |

||||

|

Male |

Female |

Male |

Female |

Male |

Female |

Male |

Female |

|

|

Dosa |

6.0±0.0 |

7.0±1.8 |

6.33±1.0 |

6.8±0.8 |

6.0±0.9 |

7.0±0.7* |

6.0±0.9 |

7.0±0.6* |

|

Mondial |

7.33±1.9 |

6.8±1.7 |

6.33±2.3 |

6.0±2.2 |

6.0±1.5 |

5.4±2.2 |

6.33±2.1 |

6.2±1.8 |

|

Mumbi |

7.33±1.0 |

7.4±1.1 |

7.0±1.5 |

7.0±0.7 |

6.0±1.8 |

6.6±0.8 |

6.33±1.4 |

7.4±1.1 |

|

Jacob 2005 |

4.66±1.4 |

4.4±1.7 |

6.33±2.2 |

6.0±1.5 |

6.0±1.8 |

5.4±1.1 |

6.33±2.3 |

5.6±1.7 |

|

Banso |

6.66±1.9 |

6.4±1.1 |

7.33±0.5 |

6.8±1.2 |

6.33±1.4 |

6.8±1.2 |

7.33±1.9 |

7.0±0.9 |

|

Cipira |

7.0±0.9 |

7.8±0.4* |

7.33±0.5 |

6.6±1.6 |

8.0±0.0 |

7.0±1.5 |

8.0±0.9 |

7.4±0.8 |

|

Belo |

5.66±2.1 |

6.4±1.3 |

7.33±0.5 |

7.2±0.4 |

6.33±2.6 |

6.6±0.5 |

6.66±2.1 |

7.2±0.4 |

(*): For the same sensory attribute and for each potato variety, the value with this symbol is significantly higher (p≤0.05)

The tuber quality parameters for processing, represented by the external aspects (tuber size, shape and eye-depth) and the internal aspects (Dry matter, Moisture content, soluble solids, pH, titratable acidity, flesh colour and browning) are influenced by tuber variety. The tubers of Cipira, Mumbi, Banso and Belo varieties are suitable for frying, mashing and roasting. Considering frying, Cipira and Mumbi with respect to size are ideal for fries while Banso and Belo are ideal for crisps. On the other hand, Dosa and Jacob are better suited for mashing and roasting while tubers of Mondial are suitable for boiling and more appropriate to be consumed in the form of salads. The overall acceptability of potato fries and boiled potatoes by a constituted panel indicated that Cipira, Banso and Mumbi varieties were most appreciated for both products. Each of these varieties is therefore of importance as its cultivation can target a particular processing technique.

We are grateful to FARA/PARI project for providing the finances for the execution of this study. We are also particularly grateful to the panel members that participated in the sensory analysis as well as to Dr Ir Augustin Kouevi and Dr. Oluwole Fatunbi both of FARA for the guidance and counselling throughout the research process.

FAO. The potato - International year of the potato 2008.

View ArticleHussain T. Potatoes: ensuring food for the future. Adv Plants Agric Res. 2016; 3(6):178-182. DOI: 10.15406/apar.2016.03.00117

View ArticleCIP (Centre International de la Pomme de Terre). Program report: 1993-1994. Lima, Peru. 1999.

Fontem DA, Demo P and Njualem DK. "Status of potato production, marketing and utilisation in Cameroon," In Proceedings 9th ISTRC-AB Symposium. Mombasa, Kenya.1-5, November 2004; 18-25.

FAOSTA. Food and Agriculture Organization of the United Nations, 2014.

Scott GJ, Rosegrant MW and Ringler C. Roots and Tubers for the 21st Century Trends, Projections, and Policy Options. Food, Agriculture, and the Environment Discussion, Paper 31, 2000.

Abass, AB, Asenge ES, Uzaribara E, Nduruguru GT, Mulwa RM and Apolot S. Quality Assurance for Potato Crisps Processing: A Training Manual, ASARECA, 2014.

Kabira JN and Lemaga B. Potato processing: Quality evaluation procedures for research and food industry applications in East and Central Africa, ASARECA/USAID, 2003.

Feltran JC, Lemos LB. and Vieites RL. Technological quality and utilization of potato tubers. Sci. Agric. (Piracicaba, Braz.), 2004; 61(6):598-603.

View ArticleCIP. World Potato Atlas - Cameroon. Kelly Theisen, principal contributor to the revised (2006) Cameroon potato chapter, 2009.

Deffo V and Demo P. Adoption of two new potato varieties in Cameroon: Progress and constraints. American Journal of Potato Research, 2003; 80(4):263-269.

View ArticleNjualem Dk, Mendoza HA, Koi J, Demo P, Deffo V and Nana SF. Evaluation of Twelve Potato Varieties in the Northwest Highlands of Cameroon. Proceedings of the seventh Triennial Symposium of the International Society for Tropical Root Crops-Africa Branch, Cotonou, Benin; October 11-17, 1998.

Fogwe ZN. Montane resources exploitation and the emergence of gender issues in Santa economy of the Western Bamboutos Highlands, Cameroon. International Journal of Geography and Régional Planning Research, European Centre for Research Training and Development UK (www.eajournals.org) Vol.1, 2014

Lisinska G, Peksa A, Kita A, Rytel A and Tajner-Czopek A. The quality of potato for processing and consumption. Food 3 (special issue 2), Global Science Books, 2009; 99-104.

Ekin Z. Some analytical quality characteristics for evaluating the utilization and consumption of potato (Solanum tuberosum L.) tubers. African Journal of Biotechnology, 2011; 10(32):6001-6010.

AOAC. Official methods of analysis. 15th ed Washington DC. Edr. Washington DC; 1990.

Haase T, Schüler C and Heb J. The effect of different N and K sources on tuber nutrient uptake, total and graded yield of potatoes (Solanum tuberosum L.) for processing. Eur. J. Agron., 2007; 26:187-197.

View ArticleFerandes AM, Soratto RP, Moreno LA. and Evangelista RM. Effect of phosphorus nutrition on quality of fresh tuber of potato cultivars. Bragantia, Campinas, 2015; 74(1):102-109.

View ArticleDepartment of Agriculture, Forestry and Fisheries. Potatoes: Production Guideline. Pretoria, South Africa, 2013.