Vikendra Dabash

Mob: +420-775087394

E.Mail: vikendradabash@rediffmail.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 4 ISSUE: 8

Page No: 903-911

Vikendra Dabash

Mob: +420-775087394

E.Mail: vikendradabash@rediffmail.com

Vikendra Dabasha, Iva Buresovaa, Uwe Grupab

aTomas Bata University in Zlín, Faculty of Technology, Department of Food Technology, nám. G. Masaryka 5555, 760 01 Zlín, Czech Republic

bFulda University of Applied Sciences, Department of Food Technology, Food processing Engineering, Leipziger Str. 123, D 36037 Fulda

Wanda Ziemkowska(ziemk@ch.pw.edu.pl)

Anamaria Irimia(anamaria.sdrobis@icmpp.ro)

Mohammad Ghorbanpour(Ghorbanpour@uma.ac.ir)

Rui M. S. Cruz(rcruz@ualg.pt)

Dabash V., Buresova I., Grupa U, Before and after microwave heating, physio-chemical properties evaluation of the different percentage of rice bran filled low density polyethylene films and sensory evaluation of packaged milk(2019)Journal of Food Science & Technology 4(8)

Biodegradable LDPE (Low-Density Poly Ethylene) film was industrialized with the mixture of control LDPE and rice bran. Three several mixtures 5% rice bran, 10% rice bran, and 15% rice bran was used for the preparation of biodegradable LDPE film. The films were analysed for the surface morphology and physico-mechanical analysis before microwave heating and after microwave heating. LDPE film equipped with 15% rice bran was created to beat method after microwave heating on the basis of tensile strength, percent elongation, bursting strength and water vapour transmission rate. The total migration of the test packaging materials was initiated within the agreeable limit and after microwave heating also it was within the permissible limit. The effect of rice bran on the morphology of LDPE mergers was observed using SEM. The analysed outcomes display that the total migrations of food package are reliant arranged microwaving period, package material categories and simulator kinds.

KEYWORDS: Barrier Properties of Food packaging, Biodegradable film, Films, Food Packaging, Pasteurization

Food packaging is similarly entwined with earlier civilization and its earliest beginnings are rooted in man’s advancements in the production and processing of foods. Packaging represents an interface between product and the environment (Kim, M and Pometto III. AF, 1994). The principle roles of food packaging are to protect food product from outside influences and damage, to contain food and to provide ingredient and nutritional information. The goal of food packaging is to contain food in a cost-effective convenient way that satisfies industry requirements and consumer desires, maintaining food safety and minimizing environmental impact (Motey R and Lele S, 2003). Thermoplastics are widely used in packaging and fabrication of bottles and films. The major type of thermoplastic material includes polyethylene, polypropylene, polyvinyl chloride, polystyrene and other resins (Anon, 1998). LDPE was studied to enhance its biodegradability by incorporating different additives like starch. The rice bran, the outer layer of rice is a low cost, (Arvanitoyannis I. et.al., 1998, Kim M. and Pometto, A.L. 1994) under-utilized coproduct of rice milling, containing 65 – 70% of saccharides along with other constituents like protein, fat. Generally, with decreasing density Clarity improves (Jenkins W.A. and Harrington J.P, 1991). The polyethylene type to be identified fairly easily by the relationship between physical properties and the density (Kumar R, et.al., 2006). The density of the resulting polymer is determined by the reaction temperature used; the lower the reaction temperature, the higher the density (Athalyle AS., 2001). LDPE is used in film applications because of their superior tensile strength, elongation to break characteristics, and puncture resistance (Juliano B.O., 1985).

The starch granules are often used as a filler in plastic (George J., et.al., 2006). The level of starch addition is generally limited to about 10%. Another process was developed to make extrusion blown films from mixtures of starch, ethylene-co-acrylic acid and low density polyethylene (Jagannath JH, et.al., 2006). For instance, an experiment was conducted by (Nadansabapathi S, et.al., 2002) to examine properties of starch blends containing 40% polyolefin and 60% plasticized starch or 50% polyolefin and 50% plasticized starch. These materials are not used for the packing of food being re-heated in the microwave oven.

Brans have been considered as a promising material in the field of certain thermoplastic applications involving food packaging, because of its low cost, availability, biodegradability, food grade and high purity (George J., et.al. 2006). The differences in density are basically due to differences in the degree of crystallinity, which also influences the plastics melting point ranges (Frones TD et al. 2001). Polyethylene plastics have the generally advantageous property of toughness, high tensile strength and good barrier properties to moisture (Risch, and Sara J. 2009). A particular property of polyethylene plastics, which is due to their relatively low melting point ranges, is the ease with which packaging can be heat-sealed. LDPE films tend to be soft and relatively clear, whereas films made from HDPE have a crisp fell and are more opaque (Kumar R, et.al., 2006). The growing uses of microwave at home and the industry have created an expending market for microwave oven able packaging materials for heating the foods (Jagannath JH., et.al., 2006). Product homogeneity is very important in microwave heating. Most of the conventional packaging materials are transparent to microwaves (Neilsen L.E. and Landel R.F., 1994). All types of plastic materials such as polyethylene, polyester, polystyrene are all microwave transparent materials.

APPRATUS AND STANDARD:

Dial test indicator- ASTM-D374- Thickness, Elmendorf tearing- ASTM-1922- Tearing strength, Bursting meter- ASTM-D774, Water vapour transmission rate- E96, Total migration IS:9845, 1986, Surface morphology- scanning electron microscope (SEM).

2.1. Materials

Low-density polyethylene was purchased from M/S IPCL, Baroda, India. Rice bran (Kalyani- II) was procured from local rice mills and pre-dried at 600 C for 24 h in a hot air drier before compounding. Fresh milk was purchased from the local super market from the milk vendor machine.

In this study, the test packaging materials were evaluated for their compatibility through the overall migration into food simulants such as distilled water (for aqueous food products), 3% acetic acid (for acidic products) 50% ethanol (for alcoholic beverages) and n-Heptane (for fatty foods) under-stimulating condition (Nadansabapathi S. and Bawa AS., 2003). Migration values for all the LDPE bran prepared film (Tab.1) revealed that there was non-significant increase in migration value for the films containing bran.

Table 1. Total migration variation before heating & after heating food stimulants(mg/L/m) 2

|

Samples |

Condition |

Distilled water |

3% Acetic acid |

50% Alcohol |

n-Heptane |

|

LDPE control |

Before microwave heating |

2.5±0.10 |

4.5±0.29 |

9.0±0.45 |

8.0±0.34 |

|

After microwave heating |

4.0±0.10 |

4.5±0.29 |

23.5±0.25 |

33.5±0.12 |

|

|

LDPE+5% RB |

Before microwave heating |

3.5±0.12 |

5.0±0.31 |

12.0±0.40 |

10.0±0.32 |

|

After microwave heating |

4.5±0.12 |

6.0±0.31 |

26.5±0.22 |

24.5±0.21 |

|

|

LDPE+10%RB |

Before microwave heating |

4.5±0.11 |

5.0±0.31 |

9.5±0.41 |

11.5±0.29 |

|

After microwave heating |

4.5±0.11 |

6.5±0.32 |

27.0±0.21 |

21.5±0.18 |

|

|

LDPE+15%RB |

Before microwave heating |

5.0±0.10 |

5.5±0.31 |

12.5±0.38 |

9.0±0.31 |

|

After microwave heating |

6.0±0.10 |

7.5±0.33 |

28.5±0.20 |

24.0±0.20 |

Legends- LDPE-Low Density Polyethylene, RB-Rice Bran

Mean ± S.E., n= 5

2.1.2. Preparation of LDPE with incorporated rice bran

The concentration of 5-15% of rice bran was incorporated into LDPE using a twine Dr. Collins screw extruder (Twin screw extruder by Dr. Collins GmbH) and blowing into films of uniform thickness using twin screw extruderttached with film blowing equipment. It was then physically blended with low density polyethylene at different concentrations 5-15% for a period of 20-22 min. The screw speed was adjusted to 38 rpm while the torque was maintained in the range of 5-11.6 N/m. The compounded polymer strands were cooled in a cool air stream and pelletized. The pallets were then blown into films with L/D ratio of 22:1 with the help of film blowing unit in the temperature range of 130 0C to 165 0C. The film blown ratio was fixed at 4:1 and the thickness was maintained uniformly at 70µ.

2.1.3. Microwave heating

Low density polyethylene (control) and rice bran incorporated LDPE films were subjected to microwave heating. For this purpose, a domestic microwave oven (M/S. LG, Czechia) having the frequency of 2,450 MHz was used. The experimental condition set was medium high for 5 minutes. The test materials were cut into prescribed sizes (2 × 10 cm) per the requirement of the test conditions and placed in a beaker and allowed to expose to microwave for 5 minute.

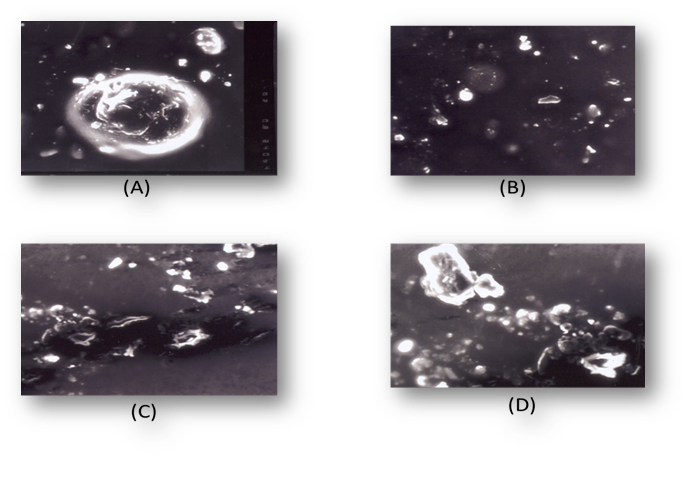

2.2. Surface morphology

The surface morphology was evaluated using a SEM (Model 100 CX , ASID 4D, JOEL operating at 20 kV. The SEM pictures revels better compatibility between rice brans and LDPE fractions at lower concentrations.

2.2.1. Milk packaging method

200 ml of fresh milk was packed 15 × 20 cm size pouches. One batch of the sample was pasteurized at 750 C in the steam kettle for 10 min. Another batch of the sample was pasteurized in the microwave oven by following the same condition applied on the packaging materials.

2.2.2. Sensory evaluation

Sensory evaluation of milk was carried out on 9-point hedonic scale with semi-trained 10 panellists. The scope pattern was 1 for Dislike extremely and 9 for Like extremely. The points of panellists were cumulated and over-all acceptability (OAA) was calculated shown in (Tab.3).

2.2.3. Statistical analysis

The results were statistically analyzed using analysis of variance (ANOVA). The differences were tested on α = 0.01 and α = 0.05 significance level using LSD test. Statistical analysis was performed using software 99. The results are expressed as mean values ± standard deviation.

3.1. Physio-mechanical properties of Control LDPE and all rice bran incorporate LDPE

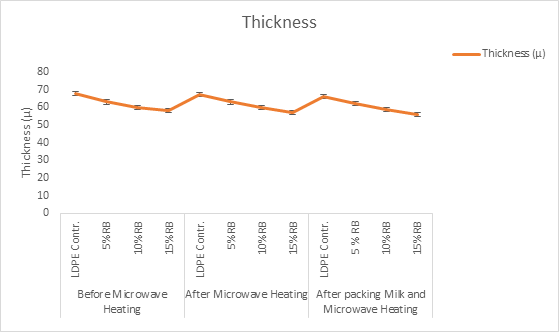

3.1.1. Thickness

The thickness of the food packaging materials is very critical as it ultimately determines the mechanical as well as permeability properties. The thickness of control LDPE (68 μm ±0.5) was decreased by incorporated rice brans to 58 ±0.2 – 63 ±0.3 μm as shown in (Fig 1). The rising amount of added brans decreased thickness of the material, however, the decrease was not significant. The thickness of the material was also decreased by the microwave heating, however, the impact of microwave heating was not significant.

Figure.1. Thickness variations of all materials in all stages

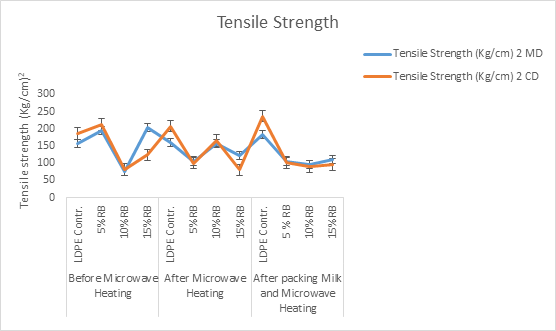

3.1.2 Tensile Strength

The tensile strength of the test materials before microwave heating was 195.43 ±1.4, 76.84 ±1.0 and 202.99 ±1.9 kg/cm2 for 5, 10 and 15% rice brans incorporated LDPE films respectively while comparing with control LDPE film of 156.97 ±1.4 kg/cm2 in the machine direction (MD). In cross direction (CD), the tensile strength of the test materials was 213.0 ±3.1, 81.44 ±1.1, 124.28 ±1.4 kg/cm2 for 5, 10 and 15% of rice bran incorporated LDPE films respectively while comparing with control LDPE film of 186.62 ±2.3 kg/cm2. The tensile strength of 5 and 15% of rice brans + LDPE films in the machine direction was found increased due to presence of rice brans when associate with control LDPE. However, in 10% of rice bran + LDPE film, the tensile strength was found decreased in the machine direction. After, microwave heating, the tensile strength of the test packaging materials in the machine direction was found decreased marginally as shown in (Fig 2). The tensile strength of 5 and 15% of rice bran + LDPE films in the cross direction was increased due to the presence of rice bran when compare with control LDPE. However, in 10% of rice bran + LDPE film, the tensile strength was found decreased in the cross direction as shown in (Fig 2). It is found that at lower concentration (5%) the dispersion and distribution of rice bran seems to be uniform but when it reaches to higher concentrations, the granules are grouped together leading to the formation of clumps, possibly due to the hygroscopic nature of rice bran. It is evident from the changes in the tensile strength of the test materials as the increased rice bran content decreases the homogeneity of the films, which in turn contributes to the decreased mechanical properties.

Figure.2. Tensile strength CD and MD in all stages of all materials

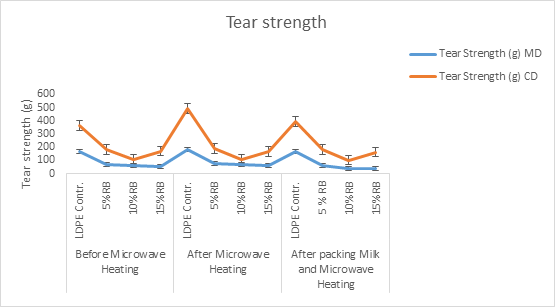

3.1.3 Tear strength

Tear strength of the test materials before microwave heating was decreasing for 5, 10 and 15% Rice bran incorporated LDPE films respectively while comparing with control LDPE film in the machine direction (MD). In cross direction (CD), tear strength of the test materials was 182.4 ±2.23, 104.0 ±1.51, 169.6 ±2.29 g for 5, 10 and 15% rice bran incorporated LDPE films respectively while comparing with control LDPE film of 363.2 ±3.78 g as shown in (Tab. 3 and Fig 4).

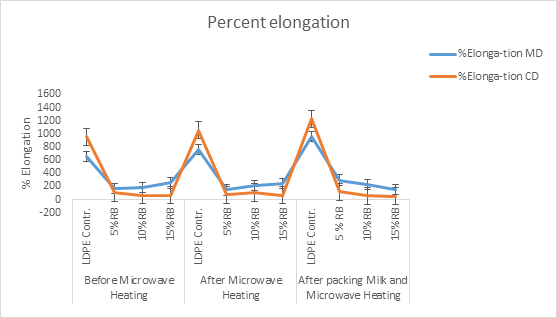

3.2.1. Percent Elongation

The percent elongation of the test packaging materials, tear strength in machine direction as well as cross directions were decreased by the incorporation of rice brans. The impact of added brans was, however, not significant as shown in (Fig 3). After, microwave heating, tear strength of the test packaging materials was decreased.

Figure. 3. Percent elongation MD and CD in all stages of all materials

Figure .4. Tear strength MD and CD in all stages of all materials

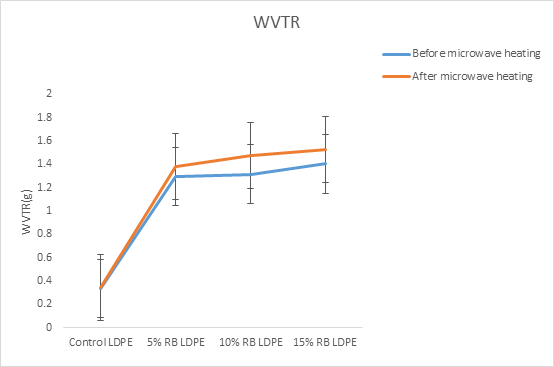

3.2.2. Water Vapor Transmission rate

Water vapor transmission rate of the test packaging materials was significantly increased by the presence of rice brans, however, the differences between samples with incorporated rice brans were not significant as shown in (Fig 5). After, microwave heating, water vapor transmission rate of the test packaging materials was found decreased due to the onset of molecular reorganization.

Figure 5. WVTR in all stages

3.2.3. Total migration

The total migration of the test packaging materials was found with in the acceptable limit and after microwave heating also it was within the permissible limit as shown in (Tab 1). (B), (C) and (D) depict the images of 5%, 10% and 15% rice bran domains dispread in LDPE matrix. At lower concentration (5%) the dispersion and distribution of rice bran seems to be uniform but when it reaches to higher concentrations, the granules are grouped together leading to the formation of clumps, possibly due to hygroscopic nature of rice bran. Deterioration in the sensory attributes, nutritional content and safety of food is caused principally by physical and chemical changes in the food during storage and by microbial spoilage (T. wang. and J.liu. 2000). Biodegradable packaging materials, like conventional packaging, should minimize these deteriorative changes in food products (Osman A., et.al. 2003). The product was well accepted on a 9-point hedonic scale as shown in (Tab 3). The test packaging materials may be used for microwave heating of liquid foods such as milk for a short duration of 5-10 minutes at 2450MHz.

3.3. AFTER MICROVAVE HEATING EVALUATION

3.3.1 Tensile Strength

After microwave heating, the tensile strength of the test materials was decreased for 5, 10 and 15% rice bran incorporated LDPE films respectively while comparing with control LDPE film in the machine direction (MD). In cross direction (CD), the tensile strength of the test materials was decreased also while comparing with control LDPE film. The changes in the tensile strength of the test materials due to microwave heating are found statistically significant and the same as shown in (Fig 3). During microwave heating, the homogeneity of the films further reduced and thus the tensile strength of the test materials decreased significantly.

3.3.2. Percentage elongation

Percentage of elongation of the test materials before microwave heating was decreased while comparing with control LDPE film in the machine direction (MD). In cross direction (CD), the percentage of elongation of the test materials was decreased also while comparing with control LDPE film. After microwave heating, the percentage of elongation of the test materials was decreased respectively while comparing with control LDPE film in the machine direction (MD). In cross direction (CD), the percentage of elongation of the test materials was 73.45 ±1.2, 109.76 ±1.9 and 65.16 ±1.3 % for 5, 10 and 15g/100g Rice bran combined LDPE films respectively while comparing with control LDPE film of 1056.45 ±8.8 %. The variations in the percentage of elongation of the test materials due to microwave heating are found statistically significant and the same as shown in (Fig 3).

3.3.3. Tear strength

After microwave heating, the tear strength of the test materials was also decreasing for 5, 10 and 15% Rice bran incorporated LDPE films respectively while comparing with control LDPE film in the machine direction (MD). In cross direction (CD), tear strength of the test materials was decreased also Rice bran incorporated LDPE films respectively while comparing with control LDPE film. The changes in the tear strength of the test materials due to microwave heating are found statistically significant as shown in (Fig 4).

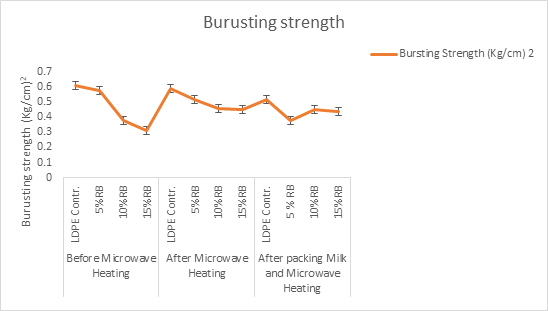

3.3.4. Bursting strength

The bursting strength of the test materials before microwave heating was found decreased Rice bran incorporated LDPE films respectively while comparing with control LDPE film of bursting strength. After microwave heating, the bursting strength was found to be decreased for 5, to 15% Rice bran combined LDPE films respectively while comparing with control LDPE film of bursting strength of 0.59 ± 0.04 Kg/Cm2. The changes in the bursting strength of the test materials due to microwave heating are found statistically non-significant and the same is shown in (Fig 6)

Figure 6. Brusting strength of all material in all stages

3.3.5. water vapour transmission rate

Intermittent weighing determines the rate of the water vapor movement through the specimen into the desiccant. In this study, the systems have been found to equilibrate after 20 days of exposure to the test conditions. Water vapor transmission rate (WVTR) of the Rice bran incorporated LDPE films has been given. It may be experimental after that WVTR values enlarged with the incorporation of bran, which may be attributed to the fading of intermolecular forces in the polymer chain (Lee KM. and Han CD., 2003). Further, due to microwave heating, the values of WVTR are found to increase, which is statistically significant as shown in (Fig 5).

3.3.6. Estimation of packaging materials

The SEM pictures expose better compatibility between rice bran and LDPE segments at lower concentrations. It is clear from the images that the bran stage in these mixtures is in rough shape. The image analysis of these films clearly shows the average particle size of bran in LDPE matrix. It is evident from the micrographs that the increased rice bran content decreases the homogeneity of the films, which in turn contributes to the decreased mechanical properties (Frones TD, et.al. 2001) For 5 and 10 %, rice bran filled LDPE films, mean diameter of rice bran particles was increased while the average area of these particles is decreased respectively) as shown in (Fig 7).

Figure. 7. SEM micrographs of LDPE with incorporated rice bran: (A) Rice bran; X800 (B) 5% rice bran incorporated LDPE; X500 (C) 10% rice bran incorporated LDPE films; X500 (D) 15% rice bran incorporated LDPE Films.

During food package interaction, polymer-packaging materials tend to leach unprocessed monomers, processing aids and other undesirable substances present in the surface of the film. Due to leaching process, the quality attributes of the food products may undergo changes, which cause the product unacceptable (T. wang, and J.liu 2003). Therefore, it is necessary to evaluate the quantity of the migrating substances into the food. As the food is a heterogeneous complex system, it is cumbersome to isolate and quantify the substances. Therefore, regulatory bodies like FDA and BIS (IS: 9845, 1986) have recommended food simulants of distilled water, 3% acetic acid, 15% ethanol and n-Heptane as the representatives of the food systems (Athalyle AS., 2001). Migration values for all the LDPE starch blend film revealed that there was a non-significant increase in migration value for the films containing starch.

The transfer values of bran filled LDPE films were within the permissible limit and these films may be suitable food contact applications (Kim TH et al, 2003). Further, after exposure to microwave heating, the migration values were found to remain within the permissible limit and thus these films may be suitable for microwave heating of foods.

Table-2. Changes in physico-mechanical properties of test packaging materials packed with milk and compared with packaging materials as such

|

Mechanical Properties |

Before Microwave Heating |

After Microwave Heating |

After packing Milk and Microwave Heating |

||||||||||

|

LDPE Contr. |

5%RB |

10% RB |

15% RB |

LDPE Contr. |

5% RB |

10%RB |

15%RB |

LDPE Contr. |

5 % RB |

10% RB |

15 % RB |

||

|

Thickness (µ) |

68± 0.5 |

63± 0.4 |

60± 0.3 |

58± 0.2 |

67± 0.4 |

63± 0.3 |

60± 0.3 |

57± 0.2 |

66± 0.4 |

62± 0.3 |

59± 0.3 |

56± 0.3 |

|

|

Tensile Strength (Kg/cm) 2 |

MD |

156.97±1.4 |

195.43±1.8 |

76.84± 1.0 |

202.99± 1.9

|

160.47± 1.4 |

106.06± 1.2 |

157.89± 1.6 |

123.40± 1.2 |

183.59± 1.9 |

106.11± 1.2 |

96.37± 1.1 |

111.69± 1.2 |

|

CD |

186.62±2.3 |

213.0±3.1 |

81.44± 1.1 |

124.28± 1.4 |

208.05± 1.8 |

100.37± 1.2 |

166.18± 1.6 |

80.48±1.1 |

236.88±2.1 |

101.01± 1.2 |

91.07± 1.1 |

96.26±1.1 |

|

|

%Elonga-tion |

MD |

655.31±13.2 |

165.80±9.3 |

186.57±10.8 |

254.51±12.3 |

758.34±16.7 |

146.92±10.5 |

212.44±12.2 |

240.55±12.7 |

955.90±17.3 |

295.05±12.9 |

231.06±11.2 |

152.67±9.3 |

|

CD |

957.12±17.4 |

107.44±9.8 |

66.83±6.2 |

68.54±6.3 |

1056.45±17.8 |

73.45±7.4 |

109.76±8.2 |

65.16±6.2 |

1230.70±18.3 |

116.07±7.5 |

56.49±5.2 |

53.32±5.1 |

|

|

Tear Strength (g) |

MD |

168.02±12.2 |

65.6± 7.34 |

64.0±6.9 |

51.2±5.1 |

179.2±8.61 |

73.6±6.3 |

64.8±5.2 |

57.2±5.1 |

169.6±9.8 |

64.0±5.1 |

38.4±4.1 |

38.4±4.1 |

|

CD |

363.2±15.5 |

182.4±12.7 |

104.0±9.5 |

169.6± 10.2 |

492.8±15.8 |

192.0±9.8 |

108.8±6.8 |

164.8±9.5 |

395.2±16.2 |

180.8±9.7 |

102.4±8.7 |

162.6±9.7 |

|

|

Bursting Strength (Kg/cm) 2 |

0.61±0.04 |

0.58±0.04 |

0.38±0.03 |

0.31±0.02 |

0.59±0.04 |

0.52±0.04 |

0.46±0.03 |

0.45±0.03 |

0.52±0.04 |

0.38±0.03 |

0.45±0.03 |

0.44±0.03 |

|

Legends- LDPE-Low Density Polyethylene, RB-Rice Bran, MD- Machine Direction, CD- Cross Direction, Contr- control

Mean ± S.E., n= 5

Table 3. Sensory Analysis and over-all acceptability (OAA) score of pasteurized and microwave heated milk

|

S. No. |

Sample |

OAA |

Observation |

|

1 |

Control Milk |

7.83±0.12 |

Like very much |

|

2 |

Pasteurized milk in control LDPE |

7.13±015 |

Like moderately |

|

3 |

Pasteurized milk in 5%RB LDPE |

7.07±0.10 |

Like moderately |

|

4 |

Pasteurized milk in 10%RB LDPE |

6.95±0.11 |

Like slightly |

|

5 |

Pasteurized milk in 15%RB LDPE |

6.88±0.13 |

Like slightly |

|

6 |

Microwave heated milk in control LDPE |

6.60±0.11 |

Like slightly |

|

7 |

Microwave heated milk in 5% RB LDPE |

3.55±0.13 |

Dislike moderately |

|

8 |

Microwave heated milk in 10% RB LDPE |

3.25±0.16 |

Dislike moderately |

|

9 |

Microwave heated milk in 15% RB LDPE |

5.75±0.14 |

Neither like nor dislike |

RB- Rice bran, OOA- Over-all acceptability, LDPE- Low density polyethylene

Sensory score range- 1: dislike extremely, 9: like very much

Mean ± S.E., n= 5

The use of rice brans also facilitated in the integration of more fillers in LDPE. Most of the work has been attentive on the expansion of stiff inoculation molded items having a higher concentration of bran., Which can decrease the ecological effect of non-biodegradable syn-thetic plastic. Bran has been mixed together with non-biodegradable plastic so that the sub-sequent film has improved biodegradation assets. Bran on blending enhances the biodegra-dability of artificial polymers mostly because of the increase in polymer surface area creat-ed after bran feasting by microorganisms and even leading to obliteration. 5% incorporated rice bran filled LDPE is more suitable for milk microwave heating, in comparison of 10, 15% in combined rice bran incorporated LDPE. As well as the rice bran incorporated amount increases in LDPE the biodegradable increase but microwave heating quality for milk decreases as shown in (Tab 3). The variations in physio-mechanical properties of the film with the Milk on compression with packaging materials are decreased as shown in (Tab 2). Total migration in rice bran incorporated LDPE increased respectively as shown in (Tab 1). Due to total migration the milk quality decreased. However, the biodegradability in-crease for the rice bran filled LDPE respectively.

The research receives specific grant from project no. IGA/2018/003 internal grant agency Tomas Bata University in Zlin, Czech Republic.

Anon (1998) Food available for microwave range and conditions of relevant container package. Packaging japan July: pp 31-39.

Athalyle AS (2001) Specialized packaging for food products. Packaging India Dec-Jan pp 34-12.

Arvanitoyannis I, Biliaderis CG, Ogawa H, Kawasaki N (1998) Carbohydr Polym: pp 36- 89. 00016-2

View ArticleBIS. 1986. Bureau of Indian Standards, IS-9845, New Delhi, India.

Chow WS, Abu Bakar A, Mohd Ishak ZA, Kager-Kocsis J, Ishiaku US (2005) Eur. Polym journal 41: 687.

View ArticleFrones TD, Yoon PJ, Keskkula H, Paul DR (2001) Polymer; 42: pp 9929. 00552-3

View ArticleKim, M, Pometto III. AF (1994) Food packaging potential of some novel degradable starch-polyethylene plastic. J Food port 57:1007-1012. PMid:31121724

View Article PubMed/NCBIMotey R, Lele S (2003) Plastics films for processed food -special requirements. Packag-ing India; 36 :12 Dec - Jan.

George J, Kumar R, Jayaprahash, Nadansabapathy S, Bawa AS (2006) Rice bran filled bi-odegradable LDPE films: Development and characterization for packaging applications. Journal of applied polymer science, 102:4514-4522.

View ArticleGalgali G, Agarwal S, Lele A (2004) Polymer; 45: pp 6059.

View ArticleJuliano BO (1985) Rice Chemistry and Technology; AACC: St. Paul, MN.

Jenkins WA, Harrington JP (1991) Packaging foods with plastics. Technomic Publishing Co., Lancaster, Pa.

Kumar R, Nadanasabapathi S, Bawa AS (2006) Microwave and Dielectric heating in Food Processing. Beverage and food world, 33 (10): 31-34.

Jagannath JH, Nandansabapathi S, Bawa AS (2006) Effect of starch on thermal, mechan-ical and barrier properties of low Density Polyethylene. Journal of applied polymer science; 99 (6): 3355-3364.

View ArticleKumar R, Nadanasabapathi S, Bawa AS (2006) Microwave and Dielectric heating in Food Processing. Beverage and food world; 33 (10): 31-34.

Kim TH, Lim ST, Lee CH Coi HJ, Jhon MS. J (2003) App. Polym. Sci. 87: pp 2106.

View ArticleKim M, Pometto, A.L (1994) J Food Prot, 57: pp 1007. PMid:31121724

View Article PubMed/NCBILee KM, Han CD (2003) Polymer; 44: pp 4573. 00444-0

View ArticleNadansabapathi S, Srivastav AN, Bawa AS (2002) Packaging design criteria for moisture sensitive foods. Package India; 35 (5): 7-13.

Nadansabapathi S, Bawa AS (2003) Packaging requirements for processed foods of De-fence intrest, Bever. Food wld; 30 (5): 54-58.

Neilsen LE, Landel R.F (1994) Mechanical properties of polymers and composites, 2nd ed; Marcel Dekker: New York.

Osman A, Mittal V, Morhidelli M, Suter UW (2003) Macromolecules 36: pp 9851.

View ArticleRisch, Sara J (2009). Food packaging history and innovations. Journal of agriculture and food chemistry. 57(18): pp 8089-8092. PMid:19719135

View Article PubMed/NCBIT. wang, J.liu (2000). a review of microwave curing of polymer materials. J. electron. Manuf, 10(200): pp 181-189.

View ArticleZhong Y, De kee D (2005,). polym. Eng Sci., 45: pp 469.

View Article