Jianmei Yu

Department of Family and Consumer Sciences, North Carolina A&T State University, Greensboro, NC 27411, USA. Phone: (+1) 336-285-4861

Email: jyu@ncat.edu

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 3 ISSUE: 6

Page No: 516-526

Jianmei Yu

Department of Family and Consumer Sciences, North Carolina A&T State University, Greensboro, NC 27411, USA. Phone: (+1) 336-285-4861

Email: jyu@ncat.edu

Jianmei Yu 1*, Ivy N. Smith 1, Guibing Chen 2

Jianmei Yu, Influence of Grape Pomace Inclusion on Physical and Chemical Properties of Corn-Based Extrudates (2018)SDRP Journal of Food Science & Technology 3(6)

This study investigated the feasibility of using grape pomace (GP) as a source of dietary fiber (DF) and polyphenol for extruded corn-based product and evaluated the impacts of GP level on the physical properties and chemical composition of extrudates. A 4x3 two-factor factorial design was used to for extrusion experiment. The two factors were the level of GP inclusion (0, 2.5, 5.0 and 10%) and moisture content (13, 15 and 17%) of the formula. The extrusion was conducted at pre-determined temperature, feeding rate and screw speed using a twin-screw extruder. Data show that adding GP in the formula caused product darkening, decreased product expansion ratio (ER), hardness and brittleness (P<0.05). The feed moisture showed greater impacts on the ER and texture than GP content. Lower feed moisture (≤15%) resulted in crunchy product with better puffy properties at all GP level. Addition of GP increased total dietary fiber and polyphenol contents in dose-dependent manner (P<0.0001) and reduced in vitro starch digestibility of extrudate (P<0.05). Therefore, GP has great potential to serve as DF and polyphenol source in extrusion cooking, but the extrusion parameter such as GP content and moisture must be well controlled to minimize the undesirable effect of GP on product.

Key Words: Extrusion, Grape pomace, Color, Expansion Ratio, Texture, Dietary Fiber, Polyphenol, Starch Digestion

Extrusion cooking is a high-temperature, short-time process in which moistened, expansive, starchy and/or protenacious food materials are plasticized and cooked in a tube by a combination of moisture, pressure, temperature and mechanical shear, resulting in molecular transformation and chemical reactions (Singh et al., 2007). The extruded product is often called extrudate. Extrusion offers the means to convert whole grains to palatable and convenient products. The ability of extrusion cooking to destroy antinutritional factors and microbes while increasing the digestibility of protein and starch makes extrusion well-suited to producing nutritious foods for at-risk populations, particularly infants and children (Camire, 2011). Extrusion cooking has been reported to destroy mycotoxins in cereal grains and legumes (Pineiro et al., 1999; Meister, 2001; Zheng et al., 2015).

Most of extruded products are cereal-based, for example, ready-to-eat breakfast cereal, pasta and extruded snacks, and the main component of these products is starch. Extrusion increased the proportion of rapidly digestible starch (RDS) and reduced the proportion of slowly digestible starch and resistant starch (Sun et al., 2006; Robin et al., 2016). Extruding a corn–millet blend, with or without prior fermentation increased in vitro starch digestibility from 20 mg/maltose/g starch to over 220 mg/maltose/g starch (Onyango et al. 2005). Consumption of RDS can cause a rapid rise in blood sugar and insulin levels after meals that can lead to insulin insensitivity and Type 2 diabetes (Gannon & Nutall, 2006; Lee et al., 2012), and may be partially responsible for obesity (Chae, et al., 1997). Extrusion decreased the insoluble dietary fiber (IDF) content in rice, wheat and oat brans depending on the screw speed (Gualberto et al., 1997; Oladiran and Emmambux, 2018).

However, the digestibility of starch in extruded products could be modified by blending cereal based ingredient with other ingredients such as legume and dietary fiber (Pérez-Navarrete et al., 2006; Brennan et al., 2008). The addition of wheat bran, fruit and vegetable by-products and processing at high barrel temperatures reduced starch digestibility (Altan et al., 2009; Brennan et al., 2012). Grape pomace (GP) is a renewable underutilized agricultural by-product rich in IDF and polyphenols and has great potential to serve as a source of dietary fiber and polyphenol to fortify extruded food. GP accounts for about 20-25% of grapes crushed for wine making (Laufenburg, 2003), and contains up to 60% of IDF (Yu et al., 2012) and 4.8-5.4% of polyphenols (Makris, et al., 2007) depending on the variety of grape. The majority of GP polyphenols has been reported to be highly polymerized condensed tannin which may form complex with fiber and are non-extractable unless strong acidic treatments are applied (Arranz et al., 2010), but extrusion was reported that extrusion processing increased the biologically important monomers and dimers of GP procyanidins (Khanai et al., 2009). The presence of grape seed polyphenols in starch solution significantly reduced the in vitro digestibility of starch in dose-dependent manner and inclusion of GP in bead recipe also reduced the in vitro digestibility of wheat starch (Yu et al., 2016). The inclusion of GP in cassava-soy composite lowered the rate of starch digestion and in vitro glycemic index (Oladiran and Emmambux, 2018).

However, the inclusion of dietary fiber and polyphenol rich agricultural by-products in the extruded food formula may also have some undesirable effects on the product quality such as color, expansion ratio, texture and chemical composition (Korkerd et al., 2016), which may influence consumer acceptance of the extruded product. The objective of this study was to evaluate the effect of different GP content on the physical properties (color, expansion ratio and mechanical texture), chemical composition (proximate composition, dietary fiber and polyphenol) and in vitro starch digestibility of extruded corn-based product.

2.1 Materials: Yellow corn grits was used as base ingredient for extrusion. Muscadine Carlos grape pomace (GP) was collected from a winery located in North Carolina, USA. The GP was dried in a vacuum oven at 75-80°C overnight, then crushed using a blender to the particle size similar to grits.

2.2 Experimental Design for Extrusion: A 4x3 two-factor factorial design was used to for extrusion experiment. The two factors were the level of grape pomace inclusion and moisture content of the formula. Yellow corn-grits was mixed with different amount of GP and water to final GP levels of 0, 2.5, 5, and 10% (w/w). At each GP level, the moisture of the mixture was 13, 15, and 17% (w/w). The mixtures were fed into a co-rotating twin-screw extruder (Brabender® Instruments, Inc., South Hackensack, NJ USA) at feeding rate of 100g/min, extrusion temperature 160 °C and screw speed 175 rpm. The extrusion temperature and screw speed were selected according to the results of our previous study (unpublished data). At each moisture level, the product with 0% GP served as control. The product produced by the extrusion process was named as extrudate in the rest of the manuscript.

2.3 Measurements of physical properties of extrudates

2.3.1 Expansion ratio (ER) The expansion ratio is also called puff ratio. The ER was calculated as the diameter of extrudate divided by the diameter of extruder die. The diameter of extruded products was measured using a caliper. Ten measurements were taken for each sample and results were recorded as the average of these measurements.

2.3.2 Color measurement Color was measured by ICE system using Konica-Minolta MC-3500d Spectrophotometer (Tokyo, Japan). To obtain homogenous samples, the product was ground into powder and collected in clear petri dish. The L*, a* and b* values were recorded, where L* represents brightness and darkness with L*= 0 as black and L* = 100 as white, a* and b* represent neutral gray value at a*= 0 and b* = 0 and represent green and blue at negative values and red and yellow at positive values, respectively. For each sample, 5 measurements were taken at different point and results were expressed as mean ± standard deviation.

2.3.3 Texture Measurement The texture of the product was measured by 3-point bending method using TA-XT2 Texture Analyzer (Texture Technologies Corporation, Scarsdale, NY) with the 3-point bend attachment (TA-92). The 3-point bending method measures the hardness, brittleness and toughness of the product simultaneously. The measurement for each sample was replicated 10 times.

2.4 Measurements of chemical properties of GP and extrudates

2.4.1 Proximate composition The proximate compositions, including moisture, ash, crude protein, crude fat and total carbohydrate, of dry GP and extrudates were measured. The moisture contents were determined by vacuum oven drying method using an Isotemp Vacuum Oven (Fisher Scientific, Georgia, USA). The samples (5.000g/each) were dried at 80°C for 24 hrs and the weight losses were recorded. The ash content was determined using a Barnstead Thermolyne 30400 muffle furnace (Dubuque, Iowa, USA) by heating samples (1.000g/each) at 550˚C for 5 hours. The crude protein contents of the samples were determined by a combustion method using 2400 CHN Elemental Analyzer (Perkin Elmer, Waltham, Massachusetts, USA) using a conversion factor of 5.46. Crude fat contents were determined by semi-automated Soxlet method using Soxtec 2050 Extractor (Hilleroed, Demark) and petroleum ether. The carbohydrate

contents of samples were determined by difference. All measurements were conducted in triplicate and results were expressed as mean ± standard deviation. Because corn-based extrudate is low moisture and low fat product, the ash and protein contents of the product was measured directly without defatting and drying, and the results were expressed as percentage of the component in the extrudate.

2.4.2 Determination of polyphenols of GP: Total polyphenol content (TPC), total flavonoid

(TF), total anthocyanin (TA) and condensed tannin (CT) of GP were determined. About 1.000g GP and 3.000g of ground extrudate were weighed into a 50 ml elementary flask and extracted with 2x25 ml of 75% ethanol, respectively. The polyphenol concentration (µg/ml) of the extract was determined by Folin-Ciocalteu method (Singleton et al., 1999) and converted to µg gallic acid equivalent per gram sample (GAE µg/g) based on the volume of extract and sample weight. Total anthocyanin (TA) was determined by AOAC method 2005.02 (2006) and expressed as mg cyaniding/g sample. Total flavonoid (TF) was determined by the method reported by Xu and Chang (2007) and result was expressed as catechin equivalents (µg of CAE/g sample). The condensed tannins were measured colorimetrically using Vanillin-HCl Assay modified by Hagerman (2002) and expressed as mg catechin/g sample.

2.4.3 Determination of Total dietary fiber (TDF) and insoluble dietary fiber (IDF) of GP:

The TDF and IDF contents of GP were determined according AOAC method 991.43 (AOAC, 1995) in triplicate using a TDF kit (Sigma-Aldrich, St. Louis, MO, USA). The soluble dietary fiber (SDF) was calculated by the difference between TDF and IDF.

2.4.4. Determination of TPC and TDF of Extrudate: For extrudate samples, only TPC and TDF were determined. About 3.000g of ground extrudate was weighed into a 50 ml elementary flask and extracted with 2x25 ml of 75% ethanol. The polyphenol concentration (µg/ml) of the extract was determined by Folin-Ciocalteu method (Singleton et al., 1999) and the TPC of extrudate was expressed as GAE µg/g sample. The TDF contents of extrudates were determined according AOAC method 991.43 (AOAC, 1995) using a TDF kit (Sigma-Aldrich, St. Louis, MO, USA). TPC and TDF analysis were conducted in triplicate for each extrudate sample.

2.4.5. In vitro starch digestibility: The effect of GP inclusion and feed moisture on the digestibility of corn starch of extruded products was evaluated by in vitro amylase digestion method in which the reducing sugar (RS) content of digesta was used as indicator of starch digestion. Briefly, 2.00g of dry sample powder was suspended in 20 ml of phosphate buffer (pH

6.8, 10 mM) in a 50 ml flask, and 0.1 ml of heat stable α-amylase solution (Sigma-Aldrich, St. Louis) was added. The digestion was conducted in a water bather shaker at 37°C for 60 min. The enzyme hydrolysis reaction was terminated by adjusting pH to 4.5-4.7 using 6N HCl solution. The digestion experiment was conducted in duplicate for each sample. The RS was determined by Dinitrosalicylic (DNS) Acid colorimetric method (Gusakov et al., 2011).

2.5 Data Analysis

The impacts of GP and moisture on color, texture and proximate composition data were analyzed by post-ANOVA Duncan multiple range comparison, and the effects of GP level on expansion ratio, TDF, and TPC data were analyzed by Regression Analysis using SAS 9.4 (SAS Institute Inc. Carry, NC, USA).

3.1 Chemical composition of GP used for extrusion

To avoid extreme discoloration of the product, the pomace of Muscadine Carlos, a light color grape variety, was used in this study. Table 1 shows that the GP used in the extrusion was high in mineral (5.43% ash), low in fat, but contained significant amount of crude protein (12.24%). Major carbohydrate in the GP is insoluble dietary fiber which is 72% of total carbohydrate. In addition, the GP also contains significant number of total flavonoids and condensed tannin. However, anthocyanin was not detected in the GP.

Table 1. Chemical Composition of Muscadine Carlos Pomace used for extrusion

|

Proximate Composition

|

Dietary Fiber |

Type of Phenolics |

|

|

Moisture (%) |

4.89±0.17 |

TDF (%) 58.26±0.57 |

TP (mg GAE/g 17.48 ±1.02 GP) |

|

Ash (%) |

5.43±0.03 |

IDF (%) 52.96±0.50 |

TF (mg 7.25 ±0.35 Catechin/g GP) |

|

Crude Fat (%) |

3.69±0.09 |

SDF (%) 5.30±0.40 |

CT (mg 9.49±0.10 Catechin/g GP) |

|

Crude Protein (%) |

12.24±0.34 |

|

TA (mg ND cyaniding/g GP) |

|

Total Carbohydrate (%) |

73.36±0.37 |

|

|

3.2 Effects of GP on appearance and color of extrudates

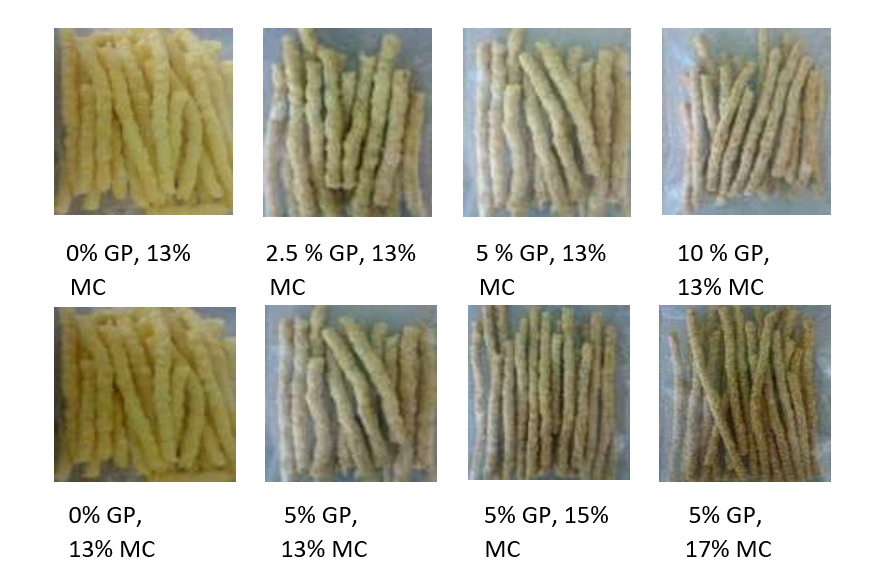

The appearance of extruded product is shown in Fig, 1. At constant extrusion moisture (13%), the product color changed from light brown to medium brown as GP content increased from 2.5% to 10%. At constant GP content, the darkness of product increased with moisture. However, the color of the extrudate was acceptable even at 10% GP content. It was also observed that the product became “slimmer” as GP level and moisture increasing.

The appearance of the extruded product was in good agreement of color measurements (Table 2). The L* and b* values were significantly affected by the GP content of the formula (P<0.0001). Adding GP in the formula resulted in decreased L* (whiteness) and b* values (yellowness), and increased a* value (redness) at all moisture levels. The moisture of formula had small but statistically significant influence on the color of extrudates (P<0.05). The increase of a* value might be the consequences of GP color and thermal oxidation of GP polyphenols during extrusion. Although Muscadine Carlos belongs to light skin grape variety, its pomace is darker than corn grits. In addition, the pomace is rich in procyanidin monomers and polymers (Wei et al., 2017) and the oxidation of grape skin and seed proantocyanidins might increase color intensity of GP fortified food products. If the pomace of darker grapes is used in extrusion, the discoloration of the extrudate may become a more serious issue.

Fig. 1: The appearance of extruded products produced with different GP contents and moistures at 160°C and 175 rpm (MC-moisture content)

Table 2. Effects of GP content and extrusion moisture on the color of corn-based extruded products measured by L*, a* and b* values. (n=5)

|

Moisture |

GP % |

L* |

a* |

b* |

|

13%MC |

0.0 |

82.60 ± 0.36a |

3.57 ± 0.06a |

34.12 ± 0.12a |

|

|

2.5 |

76.47 ± 0.45b |

5.49 ± 0.06b |

25.58 ± 0.09b |

|

|

5.0 |

73.02 ± 0.46c |

5.48 ± 0.11b |

21.54 ± 0.32c |

|

|

10.0 |

68.46 ± 0.35d |

6.45 ± 0.16c |

19.19 ± 0.25d |

|

15% MC |

0.0 |

79.40 ± 0.45e |

3.32 ± 0.01d |

31.36 ± 0.73e |

|

|

2.5 |

75.78 ± 0.11f |

5.36 ± 0.02e |

25.05 ± 0.21f |

|

|

5.0 |

71.16 ± 0.10g |

5.60 ± 0.19b |

20.37 ± 0.26g |

|

|

10.0 |

69.04 ± 0.47d |

6.20 ± 0.05f |

19.74 ± 0.29h |

|

17%%MC |

0.0 |

81.90 ± 0.30h |

3.98 ± 0.27g |

32.87 ± 0.65i |

|

|

2.5 |

75.11 ± 0.38i |

5.82 ± 0.11h |

25.99 ± 0.46b |

|

|

5.0 |

70.85 ± 0.41g |

5.97 ± 0.07h |

22.72 ± 0.14j |

|

|

10.0 |

69.04 ± 0.47d |

6.59 ± 0.01c |

18.77 ± 0.07k |

3.3 Effects of GP on expansion property of extrudates

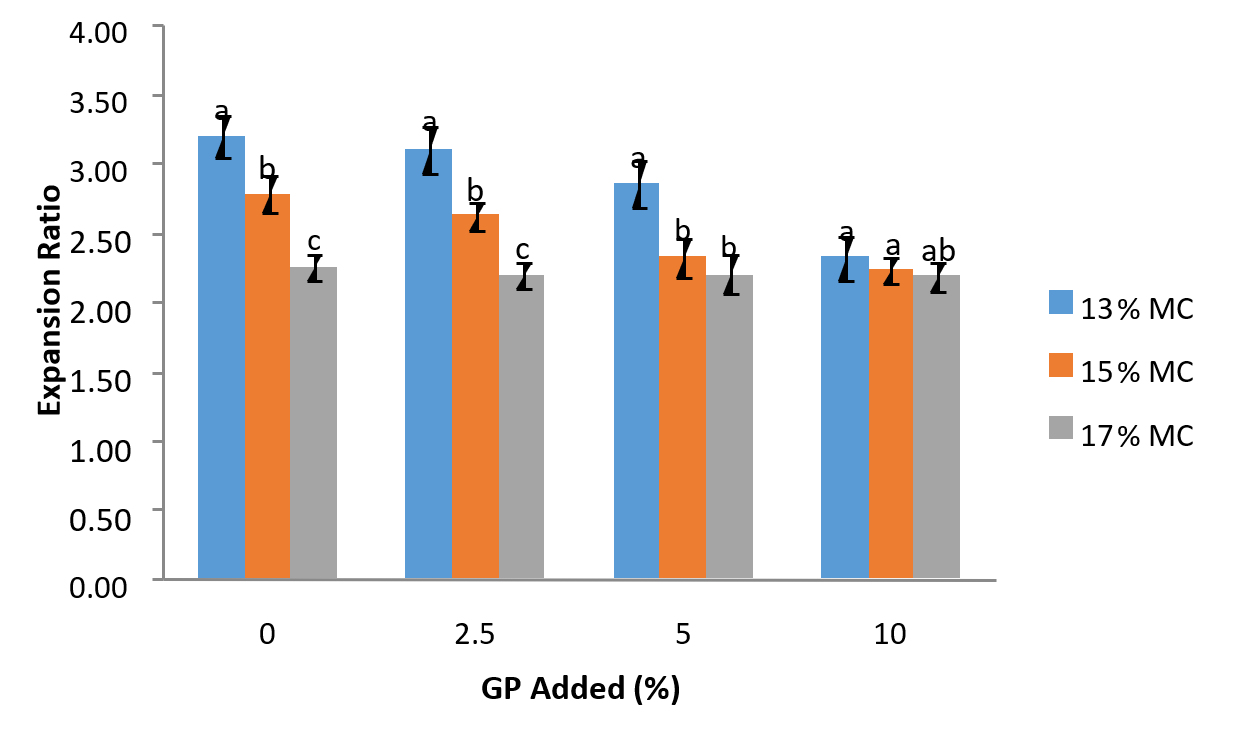

The extrusion is usually carried out under high temperature and high pressure. At the outlet of extruder, the product puffs due to the sudden pressure reduction. The puffy property of the extruded product is usually measured by radial expansion ratio (ER) and bulk density. The ER was measured as an indicator of puffy property in this study. Both GP content and feed moisture showed significant impacts on the ER of extrudate (Fig. 2). At constant moisture, the ER of extrudate inversely associated with GP inclusion level. The significant decrease in product ER was observed at GP content 5% and higher (P<0.05). This can be explained by the high insoluble fiber (TDF) content of GP because it was found that the high IDF contents reduced ERs and created denser products (Jing and Chi, 2013; Fleischman et al., 2016). At constant GP level, the ER of extrudate inversely correlated to moisture and the feed moisture had greater impact on ER and texture than GP content, particularly, at moisture higher than 15% (P<0.0001). Lower moisture (<15%) formula resulted in larger ER and crunchy product, but higher moisture led to dense and tougher product. This is because the moisture content of formula had a negative impact on starch gelatinization and reduced the porosity of the extrudates (Obradović et al., 2014). There was also interaction between moisture and GP level. Higher GP level and higher moisture resulted in smaller ER of the extrudates (P<0.05). Therefore, the moisture and GP level of the feed formula have to be well controlled to get extrudate with desired puffy property.

Table 3. Proximate Composition of Extruded Products

|

GP (%) |

Moisture (%) |

Ash (%) |

Fat (%) |

Protein (%) |

Carbohydrate (%) |

|

|

13% Moisture |

0 |

5.68±0.26a |

0.36±0.01a |

0.65±0.15a |

6.58±0.07a |

86.72 |

|

2.5 |

5.95±0.10b |

0.41±0.02b |

1.17±0.16b |

6.58±0.09a |

85.88 |

|

|

5 |

5.86±1.14b |

0.42±0.01b |

1.99±0.61c |

6.75±0.00b |

84.98 |

|

|

10 |

4.78±0.06c |

0.51±0.02c |

2.41±0.19cd |

6.88±0.00c |

85.44 |

|

|

15% Moisture |

0 |

10.71±0.05d |

0.22±0.02d d |

1.05±0.14b |

6.55±0.06 a |

81.47 |

|

2.5 |

10.59±0.07d |

0.35±0.02ea |

1.49±0.11e |

6.68±0.03 d |

80.89 |

|

|

5 |

10.57±0.04d |

0.46±0.09fe |

2.07±0.40cd |

6.71±0.03d |

80.49 |

|

|

10 |

10.44±0.05e |

0.55±0.04cc |

3.48±0.16e |

6.70±0.05d |

78.84 |

|

|

17% Moisture |

0 |

12.94±0.06f |

0.28±0.03f |

0.98±0.04b |

6.30±0.03e |

79.50 |

|

2.5 |

12.21±0.06g |

0.42±0.03b |

1.74±0.04f |

6.32±0.06e |

79.32 |

|

|

5 |

12.53±0.06h |

0.39±0.12a |

2.59±0.03g |

6.50±0.10 a |

77.99 |

|

|

10 |

12.05±0.03i |

0.52±0.04c |

3.54±0.13e |

6.60±0.01a |

77.28 |

In same column, data with same superscript are not significantly different at P<0.05.

Fig 2. The expansion ratio of corn-based extruded products at different GP contents and extrusion moistures (MC-moisture)

3.4 Effect of GP on the texture of extrudate

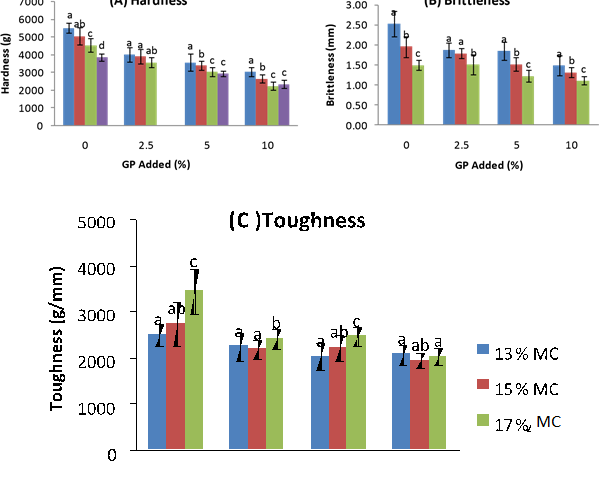

The hardness of the product was defined as the max shear forced needed to break the extruded product. At constant moisture, the hardness of extruded product decreased with increasing GP content in dose-dependent manner; at constant GP level, but decreased with formula moisture except that at 2.5% GP level where the moisture did not influence the hardness of the extrudate (Fig. 3A). It was reported that adding 5-10% ingredients rich in insoluble dietary fiber, such as oat bran and rye bran, reduced the hardness of corn-based extruded snack (Wójtowicz et al., 2014). As shown in Table 1, the dietary fiber in GP is mostly insoluble which might weaken the network structure of extruded product, thus reducing the hardness. This is, however, controversy with the finding of Brennan et al. (2008) who observed an increase in breaking force when increasing bran content in extruded corn flour. This might be attributed to the structural difference between GP fiber and bran fiber.

Crunchiness and crispness are two most important textural attributes of extruded corn puff and flake and can be mechanically measured as brittleness or fractureness using texture analyzer (Tunick et al., 2013). As shown in Fig.3B, the brittleness of the product decreased with GP content and moisture of the formula (P<0.001), and the impact of moisture was greater than GP content. In addition, there was interaction between GP level and moisture (P<0.05): the effect of moisture on the brittleness of extrudate is greater in the absence GP. At 17% moisture level, the decrease of brittleness led to loss of crunchiness and increased ‘chewiness’ or ‘sogginess’ as we experienced during sample handling and grinding.

In materials science the toughness of a material is the amount of energy per unit volume that a material can absorb before rupturing. The data show that the toughness of extruded product was also affected by both GP inclusion and formula moisture (P<0.05) (Fig. 3C). At constant GP level, the toughness of extrudates increased with the formula moisture, but at 10% GP the toughness of product was not significantly affected by moisture. At same moisture level, the toughness of the product decrease slightly but not statistically significant with GP content. The extudates with higher toughness were very chewy. The effect of moisture on the toughness of extrudate is in good agreement with the results reported by Wójtowicz et al (2014) who found that the toughness of whole wheat-based extruded breakfast cereals increased with moisture of the formula.

Overall, at proper moisture level (15% or lower), adding up to 5% GP in the formula resulted in less hard and brittle but still crunchy products under the extrusion temperature and speed used in this study (160°C, 175 rpm). When the moisture was increased to 17%, the product lost crunchiness and increased toughness significantly.

Fig 3. Texture profile of extrudates containing different amount of GP contents and moistures (A-Hardness, B-Brittleness and C-Toughness. MC- Moisture Content of formula)

3.5 Effect of GP on the proximate composition of extrudate

The influence of GP inclusion on the nutrient composition was evaluated by proximate composition as shown in Table 3. Under the selected extrusion parameters (160⁰C, 175 rpm), both GP inclusion level and formula moisture showed small but significant influence on the proximate composition of extruded products. At same formula moisture, increasing GP content resulted in small change in protein contents of extrudate, but greatly increased the ash and fat contents of extruded products (P<0.05). As shown in Table 1 and reported by others (Rao, 1994; Llobera & Canñellas, 2007; USDA, 2018), the GP has higher lipid and ash contents than corn grits, which contributed to the higher fat and ash contents of extrudates containing GP. Higher formula moisture did result in higher moisture final product.

3.6 Effect of GP on the total polyphenol and dietary fiber contents of extrudate

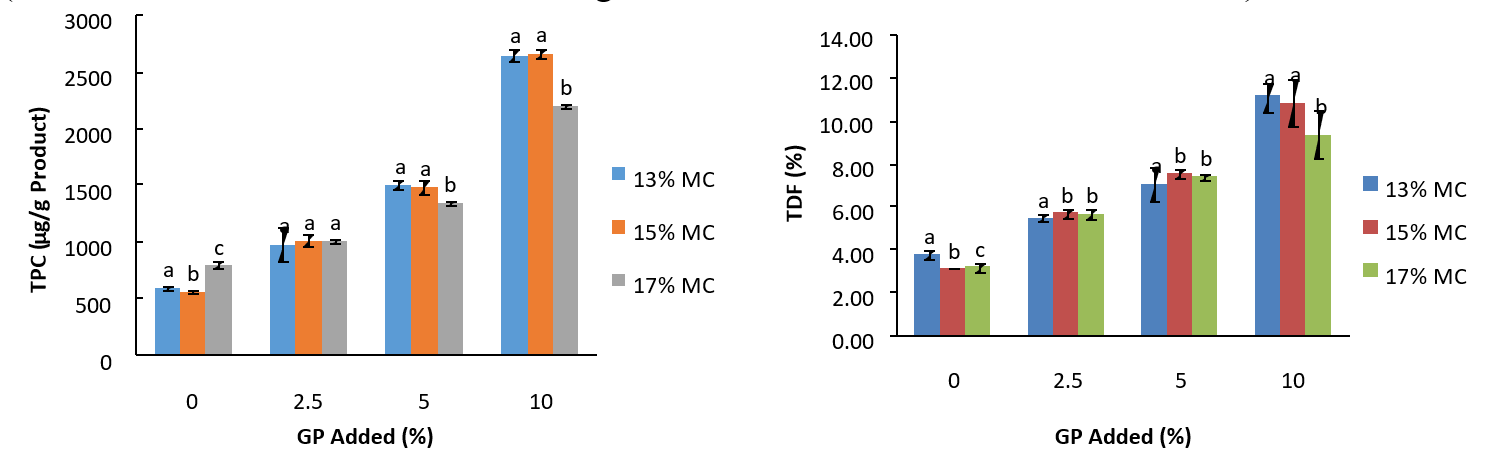

The total polyphenol content (TPC) of GP used in the study was 10.36-17.48 mg/g (dry mass). The TDF of extruded product increased linearly with increasing GP content in the formula (R2=0.981-0.995) at constant moisture (Fig. 4A). For every 1% GP addition, there was a 143.2-210.8 μg/g increase of TPC in the product depending on moisture content of formula. The rise of TPC with increasing GP level was expected because it is well known that GP is rich in polyphenols (Yu and Ahmedna, 2013) and as shown in Table 1, but the extractability of polyphenols might be influenced by extrusion process and moisture. Fig 4A shows that the extractible TPC decreased with formula moisture because higher moisture made the extrudate denser.

Total dietary fiber (TDF) of the GP used in this study was 58.26%. The TDF of extrudates increased linearly with GP level (R2=0.989-0.997) (Fig. 4B). The moisture did not significantly affect TDF content of the extrudate at all GP levels. This indicates that adding GP in the formula reduced the overall digestibility of the extruded product. It is well know that GP contains up to 75% of dietary fiber and over 60% of GP dry matter that was indigestible in vitro (Bravo & Saura-Calixto, 1998). Therefore, it was also expected that inclusion of GP in the formula would increase the TDF of final extruded product. However, Fig. 4B shows that every 1% increase in GP, there is a 0.74-0.78% TDF increase in the extruded product, which is higher than the TDF in the GP. This might be attributed to both TPC and TDF because TPC in grape seed was reported to reduce the digestibility of macronutrient (Yu et al., 2016), which could contribute to higher TDF.

Fig 4. Effects of GP inclusion level and formula moisture on the total polyphenol content (TPC)and total dietary fiber (TDF) of extruded products (MC-moisture content) (At same GP level, data with same label are not significantly different at 95% confidence interval.)

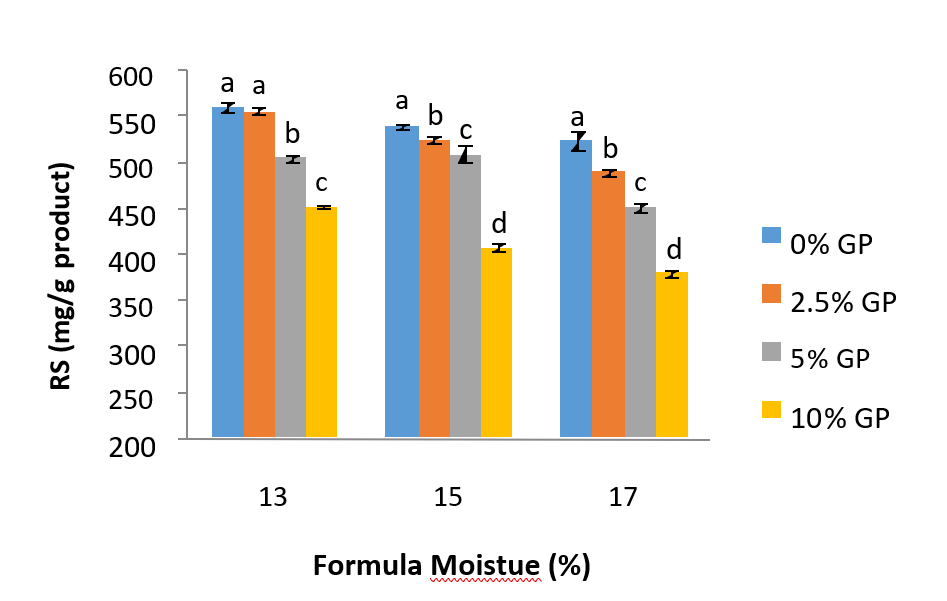

3.7. Effect of GP inclusion on the in vitro digestion of corn starch in the extrudate

The reducing sugar content of amylase digested samples was used as an indicator of starch digestion. Regardless of the extrusion moisture, GP inclusion resulted in reduced reducing sugar content in the digesta in GP dose dependent manner, which was affected by the extrusion moisture (Fig. 5). At 13% extrusion moisture, the reducing sugar concentration of amylase digested product was decreased by 0.9% to 19.5% when GP increased from 2.5% to 10%; at 15% moisture, the reduction of reducing sugar was 2.87-24.49%, at 17% moisture, 2.5-10% increase in GP resulted in 6.63-27.58% decrease in reducing sugar of amylase digested samples.

The reduced reducing sugar was partially attributed to the replacement of corn starch by fiber dense GP, and partially attributed to the interaction of GP polyphenol with digestive enzymes. Our previous study found that the in vitro digestibility of starch was linearly reduced with increasing concentration of grape seed polyphenol (Yu et al., 2016) due to the inhibitory effect of grape seed polyphenol on the activity digestive enzymes such as amylase. As mentioned early, the extrusion cooking usually increase the starch digestibility/reduce the quantity of resistant starch (Sun et al., 2006; Altan et al., 2009). Consumption of rapidly digested starch rich food product can cause a rapid rise in blood sugar and insulin levels after meals that can lead to insulin insensitivity and Type 2 diabetes (Gannon & Nuttall, 2006; Lee et al., 2012), and may be partially responsible for obesity because it was shown that pig fed with low moisture extruded corn-based feed gained more weight than those fed with non-extruded feed (Onyango et al., 2005). Therefore, the inclusion of GP compensated the undesirable influence of extrusion on the starch for the people with high risks of Type-2 diabetic and obesity.

Fig 5. Reducing sugar (RS) concentrations of amylase digested extruded products (digestas) asaffected by GP content and extrusion moisture (At same moisture level, data with same label are not significantly different at 95% confidence interval)

Inclusion of grape pomace (GP) significantly affected the physical properties and chemical composition of corn-based extruded product at the temperature and speed used in this study. The addition of GP in the formula reduced the whiteness and yellowness, and slightly increased redness of the product. Although higher GP inclusion (5% or higher) reduced the expansion ratio, hardness and brittleness, the extrusion moisture showed greater undesirable influence on the expansion ratio and texture of the extrudate than GP. The effect of GP on the texture of the product was enhanced by increasing extrusion moisture. At constant moisture, the hardness and brittleness of the product decreased gradually with increasing GP level, but increasing moisture resulted in sharp decrease of hardness and brittleness and increase of toughness. The products with better physical properties were produced at lower GP content (5% or less) and low moisture (15% or lower). Both polyphenol and dietary fiber content of the extruded product increased linearly with GP content. A 5% inclusion of GP doubled the TPC and TDF of the extrudate. Therefore, GP could serve as an inexpensive source of dietary fiber and polyphenol of extruded products to compensate the increasing of starch digestibility and loss of TDF during extrusion cooking, thus improving the nutritional quality of extruded product. However, the extrusion moisture has to be well controlled to produce desirable extrudates.

This study was sponsored by a grant awarded by USDA-NIFA, Agricultural and Food Research Initiative. Award number: 2014-67018-21633.

Altan, A., McCarthy, K.L., & Maskan, M. 2009. Effect of extrusion cooking on functional properties and in vitro starch digestibility of barley-based extrudates from fruit and vegetable by-products. Journal of Food Science, 74, E77–E86. PMid:19323745

View Article PubMed/NCBIAOAC 991.43 (1995). AOAC Official Method 991.43 Total, Soluble, and Insoluble Dietary Fibre in Foods. AOAC Official Method of Analysis, pp 7-9.

Arranz, S., Silván, J.M., & Saura-Calixto, F. (2010). Non extractable polyphenols, usually ignored, are the major part of dietary polyphenols: a study on the Spanish diet. Molecular Nutrition and Food Research, 54, 1-13. PMid:20540148

View Article PubMed/NCBIBravo, L. & Saura-Calixto, F. (1998). Characterization of dietary fiber and the in vitro indigestible fraction of grape pomace. American Journal of Enology and Viticulture, 49, 135–141.

Brennan, M.A., Monro, J.A. & Brennan, C. S. (2008). Effect of inclusion of soluble and insoluble fibres into extruded breakfast cereal products made with reverse screw configuration. International Journal of Food Science and Technology, 43, 2278–2288.

View ArticleBrennan, M.A., Derbyshire E.J., Brennan, C.S. & Tiwari, B. K. (2012). Impact of dietary fiberenriched ready-to-eat extruded snacks on the postprandial glycaemic response of nondiabetic patients. Molecular Nutrition and Food Research, 56, 834–837. PMid:22648629

View Article PubMed/NCBICamire, M.E. (2011). Nutritional Changes during Extrusion Cooking. In Advances in Food Extrusion Technology (M. Maskan and A. Altan, Eds), pp: 87-102, CRC Press, Taylor & Francis Group Boca Raton, FL.

View ArticleChae, B.J., Han, I.K., Kim, J.H., Yang, C.J., Chung, Y.K., Rhee, Y.C., Ohh, S.J. & Ryu, K.H. (1997). Effects of extrusion conditions of corn and soybean meal on the physico-chemical properties, ileal digestibility and growth of weaning pigs. Association of Jewish Aging Services, 10, 170-177.

Fleischman, E. F., Kowalski, R. J., Morris, C. F., Nguyen, T., Li, C., Ganjyal, G., & Ross, C. F. (2016). Physical, Textural, and Antioxidant Properties of Extruded Waxy Wheat Flour Snack Supplemented with Several Varieties of Bran. Journal of Food Science, 81, E2726E2732. PMid:27681599

View Article PubMed/NCBIGannon, M.C. & Nuttall, F.Q. (2006). Control of blood glucose in type 2 diabetes without weight loss by modification of diet composition. Nutrition & Metabolism, 3, 16-23. PMid:16556307 PMCid:PMC1475800

View Article PubMed/NCBIGualberto, D. G., Bergman, C. J., Kazemzadeh, M. & Weber, C. W. (1997). Effect of extrusion processing on the soluble and insoluble fiber, and phytic acid contents of cereal brans. Plant Foods for Human Nutrition, 51, 187–198. PMid:9629859

View Article PubMed/NCBIGusakov, A.V., Kondratyeva, E.G., & Sinitsyn, A. P. (2011). Comparison of two methods for assaying reducing sugars in the determination of carbohydrase activities. International Journal of Analytical Chemistry, Article ID 283658. doi:10.1155/2011/283658.

View ArticleHagerman, A. E. (2002). Vanillin Assay. Copyright © 2002 by Ann E. Hagerman. All rights reserved. .

View ArticleJing, Y. & Chi, Y. J. (2013). Effects of twin screw extrusion on soluble dietary fibre and hysicochemical properties of soybean residue. Food Chemistry, 138, 884–889. DOI: 10.1016/j.foodchem.2012.12.003.

View ArticleKhanal, R.C., Howard, L.R. & Prior, R.L. (2009). Procyanidin content of grape seeds and pomace, and total anthocyanin content of grape pomace as affected by extrusion processing. Journal of Food Science, 74, 174H-181H PMid:19723202

View Article PubMed/NCBIKorkerd S, Wanlapa S, Puttanlek C, Uttapap D, & Rungsardthong V. (2016). Expansion and functional properties of extruded snacks enriched with nutrition sources from food processing by-products. Journal of Food Science and Technology, 53, 561–570.Lee, J. (2010). Degradation kinetics of grape skin and seed proanthocyanidins in a model wine system. Food Chemistry, 123, 51–56.

Lee, B. H., Eskandari, R., Jones, K., Reddy, K.R., Quezada-Calvillo, R., Nichols, B.L., Rose, D. R., Hamaker, B. R., & Pinto, B. M. (2012). Modulation of starch digestion for slow glucose release through "toggling" of activities of mucosal α-glucosidases. The Journal of Biological Chemistry, 287, 31929-31938. PMid:22851177 PMCid:PMC3442525

View Article PubMed/NCBILlobera, A. & Ca-ellas, J. (2007). Dietary fibre content and antioxidant activity of Manto Negro red grape (Vitis vinifera), pomace and stem. Food Chemistry, 101, 659–666.

View ArticleMeister, U. (2001). Investigations on the change of fumonisin content of maize during hydrothermal treatment of maize. Analysis by means of HPLC methods and ELISA. European Food Research and Technology, 213:187–193.

View ArticleObradović, V., Babić, J., Šubarić, D., Ačkar, D., & Jozinović, A. (2014). Improvement of nutritional and functional properties of extruded food products. Journal of Food and Nutrition Research, 53, 189–206.

Onyango, C., Noetzold, H., Ziems, A., Hofmann, T., Bley, T. & Henle, T. 2005. Digestibility and antinutrient properties of acidified and extruded maize-finger millet blend in the production of uji. LWT, 38, 697–707.

View ArticlePérez-Navarrete, C., González, R, Chel-Guerrero L. & Betancur-Ancona, D. (2006). Effect of extrusion on nutritional quality of maize and Lima bean flour blends. Journal of the Science of Food and Agriculture, 86: 2477–2484.

View ArticlePineiro, M., Miller, J., Silva, G., & Musser, S. (1999). Effect of commercial processing on fumonisin concentrations of maize-based foods. Mycotoxin Research, 15:2–12. PMid:23605120

View Article PubMed/NCBIRalet, M.C., Della Valle, G. & Thibault, J.F. (1991). Solubilization of sugar-beet pulp cell wall polysaccharides by extrusion cooking. Lebensmittel Wissenschaft und Technologie, 24, 107–112.

Rao, P.U. (1994). Nutrient composition of some less-familiar oil seeds. Food Chemistry, 50, 378–382. 90208-9

View ArticleRobin, F., Heinde, C., Pineau, N., Srichuwong S., & Lehmann, U. (2016). Effect of maize type and extrusion-cooking conditions on starch digestibility profiles. International Journal of Food Science and Technology, 51, 1319–1326.

View ArticleSingh, S., Gamlath, S. & Wakeling, L. (2007). Nutritional aspects of food extrusion: a review. International Journal of Food Science and Technology, 43 (8), 2278–2288.

View ArticleSingleton, V.L., Orthofer, R.O. & Lamuela-Raventos, R.M. (1999). Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods in Enzymology, 299, 152–178. 99017-1

View ArticleSun, T., Lærke, H.N., Jørgensen, H. & Knudsen K.E.B. (2006).The effect of extrusion cooking of different starch sources on the in vitro and in vivo digestibility in growing pigs. Animal Feed Science and Technology, 131, 66–85.

View ArticleTunick, M.H., Onwulata, C.I., Thomas, A.E., Phillips, J.G., Mukhopadhyay, S., Sheen, S., Liu, C.K., Latona, N., Pimentel, M.R. & Cooke, P.H. (2013). Critical evaluation of crispy and crunchy textures: a review. International Journal of Food Properties, 16, 949-963.

View ArticleUSDA, 2018. National Nutrient Database for Standard Reference Release Legacy April, 2018.

Wei, Z., Luo, J., Huang, Y., Guo, W., Zhang, Y., Guan, H., Xu, C. & Lu, J. (2017). Profile of polyphenol compounds of five Muscadine grapes cultivated in the United States and in newly adapted locations in China. International Journal of Molecular Science, 18, 631. PMid:28335440 PMCid:PMC5372644

View Article PubMed/NCBIWójtowicz, A., Mościcki, L., Oniszczuk, T., Combrzyński, M. & Mitrus, M. (2014). The effect of fiber addition on the extrusion-cooking stability and quality of enriched corn snacks. Teka. Commission of Motorization and Energetics in Agriculture, 14, 141–146.

Yu, J., McMillan, A. & Tyson, L. (2012). Solubility and digestibility characterization of dietary fiber in grape pomace. 2012 IFT Annual Meeting, Abstract

Yu, J. & Ahmedna, M. (2013). Functional components of grape pomace: their composition, biological properties and potential applications. International Journal of Food Science and Technology, 48, 221–237.

View ArticleYu, J., Mi, Y. & Ji, S. (2016). In vitro evaluating the influence of grape seed polyphenol extract on the digestibility of macronutrient. Journal of Health Science, 4, 167-176.

Zheng, H., Wei, S., Xu, Y., Fan M. (2015). Reduction of aflatoxin B1 in peanut meal by extrusion cooking. LWT - Food Science and Technology, 64: 515-519.

View Article