Wenhui Wang

Email: wangwenhui@caas.cn

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 5 ISSUE: 5

Page No: 234-243

Wenhui Wang

Email: wangwenhui@caas.cn

Yunbin Jiang1, Zhihua Wang1, Wenhui Wang1*, Huangping Guo2, Xiaohui Jia1, Wei Tong1

1 Research Institute of Pomology, Chinese Academy of Agricultural Sciences; Key Laboratory of Fruits Storage and Processing,Province Liaoning, Xingcheng 125100

2 Pomology Institute, Shanxi Academy of Agricultural Sciences, Taigu, Shanxi 030815, China.

Yunbin Jiang, Zhihua Wang, Wenhui Wang, Huangping Guo,Xiaohui Jia, Wei Tong, Production area and harvest date influence superficial scald incidence and ultra-structure of 'Suli' pear skin during long term storage (2020) Journal of Food Science & Technology 5(5) pp:234-243

The effect of production area and harvest date on the superficial scald incidence, ultra-structure of the pericarp, core browning, and related physical qualities of ‘Suli’ pears during storage period at 0 °C were investigated. ‘Suli’ fruits were harvested at Taigu and Linyi in Shanxi province of China over five different dates and then stored at 0±0.5 °C with 85-90% relative humidity for 120 or 200 days. Superficial scald was detected after 120 and 200 days of storage. Harvest date and production area significantly affected the incidence of superficial scald and the quality of 'Suli' fruits. Earlier harvest time was associated with increased incidence of superficial scald. Fruits picked at Linyi developed more severe superficial scald than fruits harvested at Taigu. Scanning electron microscope (SEM) revealed that the cuticle and wax layer of fruits from Taigu were thicker than those from Linyi after storage. The surface of earlier harvested fruits had less wax and more extensive cracking, lower pectin content, and damaged skin organization structure. The incidence of superficial scald in ‘Suli’ pears is dependent on the ultra-structure of these superficial layers, and differences may be driven by harvest date and location.

Keywords: Production area, Harvest date, Superficial scald incidence, Ultra-structure, ‘Suli’ pear

‘Suli’ pear (Pyrus bretschneideri Rehd.) belongs to the Pyrus pyrifolia white pear group, which is one of the varieties traditionally and commonly grown in China, including in the provinces of Shanxi, Anhui, Jiangsu, and Henan (Rubtsov, 1944; Wang et al., 2013). ‘Suli’ pears are favored by consumers and widely exported due to their thin skin and juicy, crisp, and sweet flesh. However, ‘Suli’ pears can be affected by superficial scald, one of the main physiological disorders affecting the postharvest quality of pears and apples (Malus sp.) during storage. Superficial scald affects not only the appearance, but also the intrinsic qualities and commodity value, and this damage can cause serious economic losses (Wang and Dilley, 1999; Lurie and Watkins, 2012; Giné Bordonaba et al., 2013; Gao, 1995).

Many attempts have been made to study the mechanisms driving the incidence of superficial scald, including influencing factors and potential prevention measures (Dong et al., 2011; Hui et al., 2010). These studies examined the relationship between the incidence of superficial scald and content of certain chemical compounds including α-farnesene, conjugated trienes, total phenols, malondialdehyde (MDA). They found that scald development is associated with the accumulation of conjugated trienes, and oxidation products of α-farnesene. Changes to these compounds can alter relative membrane permeability and the activity of polyphenol oxidase (PPO) in the peel (Huelin et al., 1970; Wang, Y., and David, S., 2013). Recently, several studies attempted to control superficial scald during the long storage. Dong et al. reported that the total waxes of ‘Red Fuji’ apple declined with increasing the incidence of superficial scald during storage under 0±1℃. However, this decline of waxes in the apple was significantly delayed when the apples treated with 1-Methylcyclopropene (1-MCP; a synthetic plant growth regulator) (Dong et al., 2012). Results from studies of pears indicated that the disease mechanisms were comparable to those in apples: 1-MCP and diphenylamine (DPA; an antioxidant) inhibited the content of α-farnesene, conjugated trienes, total phenols, and MDA, decreased the relative membrane permeability and the activity of PPO in the peel, and reduced the occurrence of superficial scald of ‘Suli’ pears during cold storage and shelf display (Niu, 2009; Tian et al., 2009; Hui et al., 2010; Wang et al., 2011). The susceptibility of different pear cultivars to superficial scald varies with many factors, such as location, harvest time (maturity) and storage conditions. Therefore, it is important to determine the optimum harvest date for each pear from the different region. In addition, there have been few reports regarding the effects of the structure of ‘Suli’ pear skin, including the wax layer, to the incidence of superficial scald.

The objectives of this study were to investigate the effects of outer pericarp structure of pear fruits harvested at different dates and production areas on superficial scald development during long-term storage and to suggest strategies using the appropriate storage index for different fruit producing areas.

2.1. Fruit materials and treatment

‘Suli’ pears were harvested weekly for 5 weeks from two commercial orchards (trees were 10-15 y old) in Taigu and Linyi of Shanxi province in 2010. These two orchards experience different climatic conditions; Taigu is in the middle of Shanxi province, while Linyi is in the south. Harvest dates at Linyi occurred from 30 August to 27 September 2010; harvest dates at Taigu were from 31 August to 28 September 2010. 300 fruits (20 fruits from each tree) were selected from the periphery, middle, and inside of 15 representative pear trees in each orchard. All chosen fruits had uniform weight and shape, without visual defects. Fruits were packed into high CO2 osmosis membrane bags (polyethylene, Shanxi Academy of Agricultural Sciences, Shanxi, China), put into corrugated cardboard boxes, transported to the Research Institute of Pomology (Chinese Academy of Agricultural Sciences, Xingcheng, Liaoning province), and stored at 0±0.5 °C (relative humidity ~85-90%) for 200 days. Initial fruit quality was assessed by measuring color, flesh firmness, soluble solid content, and seed color of ten fruits per replicate. All treatments were repeated 3 times. After storage, the samples were evaluated for quality and for incidence of superficial scald and core browning after 1 and 9 d at 20 °C.

2.2 Evaluation of scald incidence, core browning, and quality metrics

The incidence of superficial scald was calculated using the methods of Niu et al. (2009) with categories of 0-3 based on the percentage of fruit surface affected by scald: 0 indicates no scald; 1 is scald percentage ≤25%; 2 is scald percentage from 25% to 50%; 3 is scald percentage ≥50%. The categories of seed color and core browning followed established methods (Wang et al. 2005). Seed color was categorized as: 1, all white; 2, 1/3 hazel; 3, 1/2 hazel; 4, 2/3 brown; 5, all brown; 6, all dark brown. Core browning was categorized as: 0, no browning; 1, mild speckling; 2, 1/3 core brown; 3, 2/3 core brown; 4, core entirely brown.

Index of scald = [∑(category number×number of fruits in this category)/(number of total fruits×3)] ×100

Index of seed color = [∑(category number×number of fruits in this category)/(number of total fruits×6)] ×100

Index of core brown = [∑(category number×number of fruits in this category)/(number of total fruits×4)] ×100

Decay rate (rotting caused by fungal disease) = % rotting fruits/total number of investigated fruits.

Flesh firmness was determined on fruits using a GS-15 fruit texture analyzer (GUSS, Strand, South Africa). Skin was removed from an area ~20 mm in diameter on opposite sides of the equatorial region of each pear. Flesh soluble solid contents were tested by a PR-1011 A digital handheld refractometer (Atago, Tokyo, Japan). Two wedge-shaped slices were cut from the stem to the blossom end from opposite sides of each pear, and then juice was squeezed into the refractometer. All experimental tests were repeated three times.

2.3 Preparation and observation with scanning electron microscopy (SEM)

Fruits were rinsed with water to remove superficial dust and other foreign bodies. Several transverse (2mm×1mm×1.5mm) and longitudinal (2mm×1mm×2mm) sections of peel were cut with a double edge blade, and then immersed in a glutaraldehyde solution at 2.5%, pH 6.8, prepared with 0.1 mol.L-1 phosphate placed in a 4℃ refrigerator for 24 h. After rinsing with the corresponding phosphate buffer, the samples were dehydrated with tert- butyl alcohol, dipped in 100% (v/v) tertiary alcohol for 10 min, and placed in a vacuum dryer for 40 to 60 min. After drying, the samples were glued separately on the sampling units using conductive adhesive with the sample observation plane facing up. Samples were plated with gold film using a JFC-1200 model sputter coater (JEOL, Ltd., Tokyo, Japan) and then placed on a scanning electron microscope (SEM; JMC-5310LV, JEOL, Ltd.) under 10 kV acceleration voltage for observation.

2.4 Statistical analysis

Data were analyzed using STATGRAPHICS statistics software for analysis of variance (ANOVA) and regression analysis. The least significant difference (LSD) test was used to further determine significance.

3.1 Effect of different harvest areas and dates on superficial scald and core browning of ‘Suli’ pears

The incidences of superficial scald and core browning were measured when fruits were removed from cold storage after 120 and 200 days and 1 and 9 days at 20℃ (Tables 1 and 2). No fruits showed symptoms of superficial scald after 1 day at 20℃ regardless of harvest date, production area, or storage time. However, after 9 days at 20℃, all treatments showed symptoms of superficial scald. Fruits harvested earlier and/or stored longer showed higher scores for superficial scald after 9 days at 20℃. The highest index for superficial scald was 22%, which occurred in the lowest maturity fruits from Linyi.

Table 1. Effect of different harvest areas and dates on the index of superficial scald of ‘Suli’ pears during shelf life after storage

|

Production Location |

Harvest date

|

Index of scald disease |

|||||

|

After 120 d storage |

|

After 200 d storage |

|||||

|

24 h in ambient |

Shelf life 9 d |

|

24 h in ambient |

Shelf life 9 d |

|||

|

Linyi |

Aug. 30 |

0.0 |

9.0 |

0.0 |

22.0 |

||

|

Sep. 6 |

0.0 |

7.0 |

0.0 |

14.0 |

|||

|

Sep. 13 |

0.0 |

4.0 |

0.0 |

12.0 |

|||

|

Sep. 20 |

0.0 |

2.0 |

0.0 |

16.0 |

|||

|

Sep. 27 |

0.0 |

1.0 |

0.0 |

9.0 |

|||

|

Taigu |

Aug. 31 |

0.0 |

9.0 |

0.0 |

21.0 |

||

|

Sep. 7 |

0.0 |

5.0 |

0.0 |

17.0 |

|||

|

Sep. 14 |

0.0 |

1.0 |

0.0 |

7.0 |

|||

|

Sep. 21 |

0.0 |

0.0 |

0.0 |

5.0 |

|||

|

Sep. 28 |

0.0 |

0.0 |

0.0 |

2.0 |

|||

All the fruits did not show any symptoms of core browning after 120 days of storage plus 9 days at 20℃, but fruits showed symptoms of core browning after 200 days of storage plus 9 days at 20℃. The highest index for core browning was 31%, which occurred in the highest maturity fruits from Linyi. Fruits with more advanced maturity were more susceptible to core browning, and fruit harvested at Linyi showed higher index of core browning than fruit harvested at Taigu at the same harvest time.

Table 2. Effect of different harvest areas and times on the index of core browning of ‘Suli’ pears during shelf life after storage.

|

Production Location |

Harvest date

|

Index of core brown |

|||||

|

After 120 d storage |

|

After 200 d storage |

|||||

|

24 h in ambient |

Shelf life 9 d |

|

24 h in ambient |

Shelf life 9 d |

|||

|

Linyi |

Aug. 30 |

0.0 |

0.0 |

0.0 |

12.0 |

||

|

Sep. 6 |

0.0 |

0.0 |

0.0 |

25.0 |

|||

|

Sep. 13 |

0.0 |

0.0 |

0.0 |

17.0 |

|||

|

Sep. 20 |

0.0 |

0.0 |

0.0 |

30.0 |

|||

|

Sep. 27 |

0.0 |

0.0 |

0.0 |

31.0 |

|||

|

Taigu |

Aug. 31 |

0.0 |

0.0 |

0.0 |

3.0 |

||

|

Sep. 7 |

0.0 |

0.0 |

0.0 |

10.0 |

|||

|

Sep. 14 |

0.0 |

0.0 |

0.0 |

4.0 |

|||

|

Sep. 21 |

0.0 |

0.0 |

0.0 |

5.0 |

|||

|

Sep. 28 |

0.0 |

0.0 |

0.0 |

10.0 |

|||

3.2 Effect of harvest date on the initial quality of ‘Suli’ pears

Fruit maturity was reflected by the indicators of firmness, soluble solid content, and index of seed color (Table 3). As expected, fruit firmness decreased with delayed harvest. The firmness ranged from 6.36 to 5.17 kg/cm2 for pears harvested from Linyi, and from 6.96 to 5.21 kg/cm2 for pears harvested from Taigu. Soluble solids content of fruits across all harvest dates showed an increasing and then decreasing trend, likely because fruit undergo a ripening process after picking, and then consume sugar to supply energy for respiration. With delayed harvest, seed color gradually became browner, often reaching dark brown (85.8% for Linyi and 86.9% for Taigu), indicating fruits reached the full maturity state.

Table 3. Quality indices for different harvest areas and times of ‘Suli’ pears

|

Production Location |

Harvest date |

Firmness (kg/cm2) |

Soluble solids content (%) |

Index of seed color |

|

Linyi |

Aug. 30 |

6.36±0.34a |

10.83±0.56b |

37.2d |

|

Sep. 6 |

6.06±0.21a |

10.91±0.73b |

57.3c |

|

|

Sep. 13 |

5.61±0.56b |

11.51±0.92a |

72.8b |

|

|

Sep. 20 |

5.50±0.46b |

11.09±1.34b |

84.2a |

|

|

Sep. 27 |

5.17±0.27c |

11.05±0.72b |

85.8a |

|

|

Taigu |

Aug. 31 |

6.96±0.63a |

11.51±0.28c |

29.1d |

|

Sep. 7 |

6.41±0.25b |

12.67±0.94a |

42.2c |

|

|

Sep. 14 |

6.06±0.36c |

12.68±0.85a |

62.4b |

|

|

Sep. 21 |

5.61±0.41d |

12.63±0.17a |

81.3a |

|

|

Sep. 28 |

5.21±0.28e |

12.05±1.18b |

86.9a |

Data are expressed as means ± standard deviations from three replicates.

Data in the same column followed by the same lower-case letter are not significantly different (P>0.05).

3.3 Effect of different harvest areas and dates on the flesh firmness and soluble solids content of ‘Suli’ pears

Flesh firmness was strongly affected by harvest maturity and storage time (Table 4). Firmness decreased during storage and continue to decline after shelf life. With increasing shelf life, the flesh firmness of fruit declined. The firmness of the last harvested pear after long storage declined to 4.62 and 4.55 kg/cm2 and after shelf life declined to 3.58 and 3.85 kg/cm2 from Linyi and Taigu, respectively. The fruit is a living body that constantly experiences maturity and senility.

|

Production Location |

Harvest date

|

Firmness (kg/cm2) |

|||||

|

After 120 d storage |

|

After 200 d storage |

|||||

|

24 h in ambient |

Shelf life 9 d |

|

24 h in ambient |

Shelf life 9 d |

|||

|

Linyi |

Aug. 30 |

5.55±0.75a |

4.95±0.47a |

5.23±0.36a |

4.76±0.63a |

||

|

Sep. 6 |

5.29±0.32ab |

4.53±0.14b |

5.15±0.43a |

4.23±0.36b |

|||

|

Sep. 13 |

5.18±0.48ab |

4.06±0.26c |

4.99±0.32a |

4.01±0.17bc |

|||

|

Sep. 20 |

5.03±0.62b |

3.84±0.18cd |

4.14±0.25b |

3.76±0.42c |

|||

|

Sep. 27 |

4.62±0.27c |

3.31±0.75d |

3.93±0.54b |

3.58±0.25c |

|||

|

Taigu |

Aug. 31 |

5.91±0.42a |

5.31±0.28a |

5.85±0.37a |

4.89±0.38a |

||

|

Sep. 7 |

5.71±0.38a |

5.05±0.37a |

5.10±0. 48b |

4.45±0.53ab |

|||

|

Sep. 14 |

5.21±0.52b |

4.53±0.52b |

4.77±0.25bc |

4.37±0.42b |

|||

|

Sep. 21 |

5.06±0.84b |

4.35±0.83b |

4.55±0.75c |

4.13±0.65bc |

|||

|

Sep. 28 |

4.55±0.65c |

4.18±0.26b |

4.44±0.23c |

3.85±0.49c |

|||

Data are expressed as means ± standard deviations from three replicates.

Data in the same column followed by the same lower-case letter are not significantly different (P>0.05).

Soluble solids content (SSC) of fruits varied due to production area after storage and shelf life at 20 ℃ (Table 5). The SSC of fruits harvested at Linyi ranged from 10.08 to 11.08%, whereas, the SSC of fruits harvested at Taigu ranged from 11.58 to 12.31%. Taigu fruits likely contain higher SSC than do Linyi fruits due to the Taigu area experiencing a larger temperature difference between day and night.

Table 5. Effect of different harvest areas and times on the soluble solids content of ‘Suli’ pears during shelf life after storage

|

Production Location |

Harvest date

|

SSC (%) |

|||||

|

After 120 d storage |

|

After 200 d storage |

|||||

|

24 h in ambient |

Shelf life 9 d |

|

24 h in ambient |

Shelf life 9 d |

|||

|

Linyi |

Aug. 30 |

10.76±1.46a |

10.85±0.86a |

10.13±0.66b |

10.08±0.47b |

||

|

Sep. 6 |

11.05±1.34a |

11.08±0.87a |

10.93±0.85a |

10.91±0.81a |

|||

|

Sep. 13 |

10.85±0.96a |

10.94±0.95a |

10.45±0.82b |

10.35±0.94b |

|||

|

Sep. 20 |

10.68±0.42a |

10.75±1.38a |

10.22±0.54b |

10.18±0.32b |

|||

|

Sep. 27 |

10.78±0.72a |

10.98±0.53a |

10.35±0.97b |

10.14±0.75b |

|||

|

Taigu |

Aug. 31 |

11.85±0.82a |

11.91±0.56a |

11.58±0.75b |

11.63±0.88b |

||

|

Sep. 7 |

12.16±0.61a |

12.27±0.77a |

12.31±0.93a |

12.35±0.58a |

|||

|

Sep. 14 |

12.08±0.52a |

12.18±0.59a |

12.23±0.85a |

12.27±0.92a |

|||

|

Sep. 21 |

12.10±0.97a |

12.15±0.89a |

12.18±0.45a |

12.23±0.65a |

|||

|

Sep. 28 |

11.94±0.63a |

11.96±0.86a |

11.85±0.33b |

11.71±0.49b |

|||

Data are expressed as means ± standard deviations from three replicates.

Data in the same column followed by the same lower-case letter are not significantly different (P>0.05).

3.4 Effect of different harvest areas and dates on the decay rate of ‘Suli’ pear

The decay rate varied depending on harvest date and production area (Table 6). The fruit picked at Linyi on 6 and 20 September and at Taigu on 7 September showed a higher decay rate due to rain events before the harvest. Overall, the decay rate of Taigu fruits was lower than that of Linyi fruits; Taigu fruits can be considered to have better quality after storage than those from Linyi.

Table 6. Effect of different harvest areas and times on the decay rate of ‘Suli’ pears during shelf life after storage

|

Production Location |

Harvest date

|

Decay rate (%) |

|||||

|

After 120 d storage |

|

After 200 d storage |

|||||

|

24 h in ambient |

Shelf life 9 d |

|

24 h in ambient |

Shelf life 9 d |

|||

|

Linyi |

Aug. 30 |

0.0 |

7.7 |

6.0 |

9.5 |

||

|

Sep. 6* |

13.5 |

20.5 |

18.5 |

28.0 |

|||

|

Sep. 13 |

6.0 |

10.8 |

11.9 |

13.1 |

|||

|

Sep. 20* |

15.5 |

20.5 |

19.5 |

26.4 |

|||

|

Sep. 27 |

10.7 |

13.8 |

15.8 |

22.7 |

|||

|

Taigu |

Aug. 31 |

0.0 |

3.5 |

5.5 |

7.0 |

||

|

Sep. 7* |

5.0 |

13.5 |

11.3 |

16.6 |

|||

|

Sep. 14 |

0 |

5.0 |

8.1 |

8.8 |

|||

|

Sep. 21 |

0 |

6.5 |

9.2 |

10.3 |

|||

|

Sep. 28 |

0 |

7.0 |

10.5 |

13.9 |

|||

Note: * Rain occurred before harvest

3.5 Scanning electron microscopy observation results

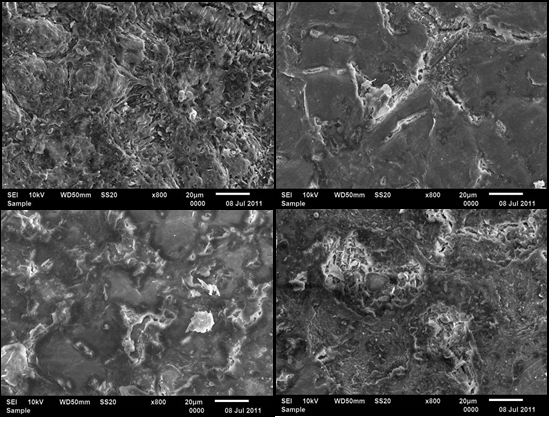

Observations of the pericarp surface indicated that there were significant differences in the structure of the fruit surface based on harvest date and location. The surface of fruits harvested 13 and 14 September 2010 from both producing areas had thicker, less cracked wax, and a series of interconnected ridged bumps (Fig. 1 A and C), whereas the surface of fruits harvested 30 and 31 August 2010 had very thin wax on the surface, arranged loosely, without ridged bumps (Fig. 1 B and D). Fruits harvested from Taigu had better surface wax structure (more wax with fewer cracks) compared to that of fruit harvested from Linyi (Fig. 1 A and B). Increased wax layer may contribute to reduced incidence of superficial scald.

Fig. 1 The pericarp surface of ‘Suli’ pears

A: Harvested 14 September from Taigu; B: Harvested 31 August from Taigu; C: Harvested 13 September from Linyi; D: Harvested 30 August from Linyi

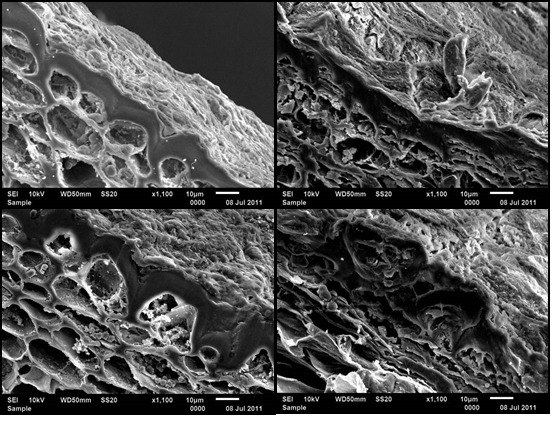

The morphology of longitudinal sections of the pericarp of fruits harvested at different times and locations were compared. The skin organization of Taigu pears harvested later was complete, with the corneous layer, pectin layer, and subcutaneous tissue tightly packed, and with increased pectin content. Each of these is protective for fruits (Fig. 2 A). The peel structure of the earliest Taigu harvest was damaged, with the corneous layer, pectin layer, and epidermal cells arranged loosely, and with minimal pectin. The epidermal cells had less pectin, and the subcutaneous tissue was deformed, indicating reduced protection (Fig 2 B). Results from Linyi followed similar trends over time as those observed in fruits from Taiga, though Taiga fruits overall showed less damage to the peel structure than did Linyi fruits.

Fig. 2 Longitudinal section of the pericarp of ‘Suli’ pears

A: Harvested 14 September from Taigu; B: Harvested 31 August from Taigu; C: Harvested 13 September from Linyi; D: Harvested 30 August from Linyi

Superficial scald is a physiological disorder characterized by brown or black patches that appear during or after storage on the skin of certain pear and apple cultivars (Lurie and Watkins, 2012). This physiopathy normally occurs after the re-establishment of room temperature conditions (20 ℃) following a period of cold storage at −1 to 4 ℃ and usually affects only the peel-forming epidermal and hypodermal layers, seldom the external parenchymal layers (Watkins et al., 1995, Bain and Mercer, 1963). After storage, the disorder continues to expand during ripening at room temperature.

The appearance of scald in apples is related to low temperature storage but also depends on ripening stage (Ingle and D’Souza, 1989). Many studies have reported that earlier harvest increases the susceptibility to chilling injury. For instance, ripe tomatoes can be stored at 7 to 10 ℃ without chilling injury, whereas green tomatoes must be stored above 12 ℃ (Cook et al., 1958). Ferrera (1995) showed that the incidence of chilling injury of early harvested ‘Songold’ plums was much higher than that of commercial plums harvested at maturity. After chilling injury, the fruit cell experiences a series of structural and functional changes, including a loss of cell turgor pressure, vesiculation, damage to cytoplasm and vacuole, degradation of cell wall or deposition of pectic substance, and deformation, collapse, and loss of cell wall structure (Xu et al., 1993; Li et al., 1997). These effects may be especially strong in cells that are still developing. This study showed similar results: after storage at low temperatures, the pericarp of fruits harvested earlier were more likely to be damaged.

In recent years, the prevention of superficial scald in globally traded fruits, including the ‘Suli’ pear, has become of increasing research importance. Gao (1995) reported that the pericarp of ‘Suli’ pears contained α-farnesene and conjugated trienes and deduced that the pathogenesis of superficial scald was essentially the same as in apples and Yali pears, where it is due to the accumulation of α-farnesene and its oxidation products. Studies of potential inhibition of superficial scald by 1-MCP in ‘Suli’ pears showed that there are two ways to control the occur of this disease: maintaining antioxidant activity in the pericarp and inhibiting the metabolism of α-farnesene. 1-MCP can increase the activity of peroxidase in the pear pericarp, inhibit the rise of malondialdehyde content, total phenols, α-farnesene, and conjugated trienes, and increase the activity of polyphenol oxidase, resulting in maintenance of high oxidation activity (Wang et al., 2011). Tian et al. (2011) reported that low temperature stress can induce oxidation stress and lead to loss of membrane integrity. Thus, increasing the content of antioxidants in the cell and improving the activity of antioxidant enzymes are effective methods to enhance fruit resistance to cold. Further examination of the applications of antioxidant compounds including 1-MCP and DPA for scald protection in ‘Suli’ pears will provide more guidance for successful storage.

Waxy coverings on plant outer layers are the last barrier for plant self-protection and play an important role in the processes of plant growth and development (Li et al., 2006). The corneous layer is an impermeable fatty substance layer deposited on the outer surface of skin cells, consisting of 15-20 layers of anucleate dead cells. These kinds of structure can help reduce evaporative losses and resist microbial invasion. Fruits grown in different environmental conditions vary in skin structure and storability. Wei et al. (2001) found differences in thickness, quality, uniformity, and appearance of the fruit skin across ‘Fuji’ apples grown under different conditions. Gong et al. (1988) reported that apples with thicker wax layers have higher storability. Our study similarly found that the wax and corneous layer of Taigu pears was thicker, and that these pears were more resistant to storage, with lower incidence of superficial scald. Fruit bagging can also alter the growth environment of fruit, result in changes to the structure of the pericarp. Bagging fruit can reduce the cutin layer and increase the frequency of surface cracks (Bu Qing-wei et al., 2009; Wei Shu-wei et al., 2010; Hao Yan-yan et al., 2011). The changing peel structure due to bagging directly affects the storability of fruit, which could also be a cause of superficial scald in late storage. The interactions of production location, picking date, and storage type with bagging technique on fruit quality deserves further study.

In conclusion, there are direct relationships between the degree of superficial scald and the integrity of skin tissue structure, moderated by the impacts of harvest location and date. In fruits with more integrity in the pericarp structure, occurrence of superficial scald is lower. Certain production locations (e.g. Taigu) and later harvest dates may increase resistance to superficial scald regardless of storage conditions. Further study of harvest and storage of ‘Suli’ pears should focus on changes to antioxidant capacity and to the structure of the fruit peel (especially changes to the wax and corneous layer), especially after lengthy low temperature stress.

The authors acknowledge support for this work from the National Modern Agricultural Industry Technology System Construction Special Funds Project (CARS-28-21)

Bain, J.M., Mercer, F.J., 1963. The submicroscopic cytology of superficial scald, a physiological disease of apples. Aust. J. Biol. Sci. 16, 442-449.

View ArticleCook, H. T., Parsons, C. S., McColloch, L. P, 1958. Methods to extend storage of fresh vegetables aboard ships of the U.S. Navy. Food Tech. 12, 548.

Dong, Y., Liu, L., Guan, J., 2011. Effects of 1-Methylcyclopropene on NO Content, NOS Activity, and H2O2 Content in Postharvest Suli Pears. Agricultural Sciences in China. 10, 797-804. 60064-3

View ArticleDong, X., Rao, J., Huber, D. J., Chang, X., Xin, F., 2012. Wax Composition of 'Red Fuji' Apple Fruit during Development and during Storage after 1-Methylcyclopropene Treatment. Hort. Environ. Biotechnol. 53, 288-297.

View ArticleFerrera, J, 1995. A Plum market for SA stone fruit. Fresh Produce Journal. Del 8, 18, 20, 23.

Gao, J., 1995. Pathogenesis and Prevention Measures of Superficial Scald of Dangshansu Pear. Storage Transportation and Preservation of Commodities. 89, 24-25. (in Chinese)

Giné-Bordonaba, J., Matthieu-Hurtiger, V. B., Westercamp, P. C., Coureau, C. D., Dupille, E. E., Larrigaudière, C., 2013. Dynamic changes in conjugated trienols during storage may be employed to predict superficial scald in 'Granny Smith' apples LWT. Food Sci. Technol. 54, 535-541.

View ArticleGong, M., Zhang, F., 1988. Studies on Relationship between Pericarp structure and Store Resistance in Apple. Shanxi Fruits. 7, 5-6. (in Chinese)

Hao, Y., Zhao, Q., Liu, Q., Li, W., 2011. Effects of the Micro-Environment Inside Fruit Bags on the Structure of Fruit Peel in 'Fuji' Apple. Acta Ecologica Sinica. 31, 2831-2836. (in Chinese)

Huelin, F. E., Coggiola, I. M., 1970. Superficial scald, a functional disorder of stored apples. V. Oxidation of α-farnesene and its inhibition by diphenylamine. Journal of the Science Food Agriculture. 21, 44-48.

View ArticleHui, W., Niu, R., Song, Y., Li, D., 2010. Inhibitory Effects of 1-MCP and DPA on Superficial Scald of 'Dangshansuli' Pear. Scientia Agricultura Sinica. 43, 1212-1219. (in Chinese)

Ingle, I., D'Souza, M.C., 1989. Physiology and control of superficial scald of apples: a review. HortScience 24, 28-31.

Li, L., Han, T., 1997. Changes of Physiology and Organization Structure in Postharvest Fruit and Vegetable Under Cold Stress. Journal of Beijing University of Agriculture. 12, 93-97. (in Chinese)

Li, W., Zhang, Z., Li, J., 2006. Plant Epicuticular Wax and Drought Resistance as Well as Its Molecular Biology. Journal of Plant Physiology and Molecular Biology. 32, 505-512. (in Chinese)

Lurie, S., Watkins, C. B., 2012. Superficial scald, its etiology and control. Postharvest Biol. Technol. 65, 44-60.

View ArticleNiu, R., 2009. Inhibitory Effects and Mechanism of 1-MCP and DPA on Superficial Scald of Dangshansu Pear [Ph. M. Dissertation]. Xi'an: Shanxi Normal University. (in Chinese)

Piao, Q., Li, C., Xia, J., Xiao, Z., Qu, S., 2009. Effects of the Micro-Environment Inside Fruit Bags on the Structure of Fruit Peel and Enzyme Activities in 'Fuji' Apple. Jiangsu Agricultural Sciences. 5, 159-161. (in Chinese)

Rubtsov G. A. Geographical distribution of the genus Pyrus and trends and factors in its evolution. The American Society of Naturalists, 1944, 78: 358-366.

View ArticleTian, G., Rao, J., Zhang, J., Dong, X., 2009. Effects of 1-MCP Treatment on Dangshansu Pear Cold Storage of Different Harvest. Acta Agriculturae Boreali-occidentalis Sinica. 18, 256-260. (in Chinese)

Tian, G., Rao, J., Zhang, J., Dong, X., Wang, S., 2009. Effects of 1-MCP treatment on superficial scald of Dangshansu pear. Journal of Northwest A & F University (Nat. Sci. Ed.). 37, 138-142. (in Chinese)

Tian, S., Luo, Y., Wang, G., 2011. Biological Basis of Postharvest Horticultural Products. Beijing: Science Press: 99-102.

Wang, J., Hui, W., Guan, J., Guo, C., Wang, P., XU, X., 2011. Inhibitory Effects and Mechanism of 1-MCP Treatment on Superficial Scald of Dangshansu Pear. Acta Bot. Boreal.-Occident. Sin. 31, 0977-0984. (in Chinese)

Wang, W., Li, Z., Wang, Z., Zhang, Y., Fu, Z., Lv, B., 2005. The effect of harvest date on quality and core brown of huangjin pear. China Fruits. 5, 13-15.

Wang, W., Jia, X., Du, Y., Wang, Z., 2013. Current Situation, Problems and Development Trend of Production and Storage of Pear in China. Storage and Process. 13, 1-8.

Wang, Y., David, S., 2013. Internal browning disorder and fruit quality in modified atmosphere packaged 'Bartlett' pears during storage and transit. Postharvest Biol. Technol. 83, 72-82.

View ArticleWang, Y., Wang, J., Song, Q., Chen, J., 2003. Occurrence Characteristics and Key Control Techniques of main diseases of Dangshansu Pear During Storage Period. Plant Protection Technology and Extension. 23, 24-25. (in Chinese)

Wang, Z., Dilley, D. R., 1999. Control of superficial scald of apples by low oxygen atmospheres. HortScience 34, 1145-1151.

View ArticleWatkins, C. B., Bramlage, W. J., Cregoe, B. A., 1995. Superficial scald of Granny Smith apples is expressed as a typical chilling injury. J. Am. Soc. Hortic. Sci. 120, 88-94.

View ArticleWei, Q., Ye, B., Mao, Z., Li, J., 2011. Characters and Difference of Anatomical Structure for Fuji Apple Pericarp in Various Ecological Regions. Journal of Fruit Science. 18, 243-245. (in Chinese)

Wei, S., Wang, H., Wang, S., 2010. Effects of Inside Fruit Bags on the Structure of Fruit Peel in 'Hongjiangjun' Apple. Shandong Agricultural Sciences. 10, 58-61. (in Chinese)

Xu, L., Bao, H., 1993. The Effects of Cold Temperature on External Morphology and Organization Structure of sweet pepper fruit. Journal of August 1st Agri. College. 16, 69-72. (in Chinese)

Xu, Y., 2011. Study on the Suitable Harvesting Date of Dangshansu Pear [Ph. M. Dissertation]. Yangling: Northwest Agriculture and Forestry University. (in Chinese)