Momoh Clement Owoicho

Department of Food Science & Technology, University of Agriculture, Makurdi, Benue State, Nigeria

Email address: momohclement86@gmail.com

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 5 ISSUE: 5

Page No: 252-256

Momoh Clement Owoicho

Department of Food Science & Technology, University of Agriculture, Makurdi, Benue State, Nigeria

Email address: momohclement86@gmail.com

Clement Momoh Owoicho, Textural Properties and Cooking Quality Characteristics of Noodles Prepared from Blends of Broken Rice (Oryza sativa), African Yam Bean (Sphenostylis stenocarpa) and Rice Flour blends(2020)Journal of Food Science & Technology 5(5)

In this study, the Textural properties and Cooking quality characteristics of noodles prepared from flour blends of broken rice (R), African yam bean (AYB) and rice bran (B) were determined, the level of rice bran was maintained at 8% (w/w) while AYB and rice flours were varied in the ratios of 100:0:0, 92:0:8, 83:9:8, 64:28:8 and 46:46:8% giving a total of five samples. The noodles produced by extrusion were characterized for textural properties and cooking quality characteristics using standard analytical methods. Cooking time ranged from 6.0 to 8.3 min with sample 46:46:8R: AYB: B taking the longest time to cook while the control (Rice noodle) cooked fastest, Percent rehydration and cooking loss was highest and lowest respectively in the control sample (Rice noodle). Tensile strength and elastic recovery and extensibility reduced with increasing addition of AYB flour. Sample 46:46:8R: AYB: B had the least of the three textural properties,

Keyword: Cooking, Textural and Noodles

Noodles are quick cooking foods that are increasingly gaining acceptance in Nigeria and gradually displacing most traditional diets that serve as breakfasts and snacks due to convenience, improved income, nutritional values, status symbol and job demands especially among urban dwellers (Okafor and Usman, 2015). The popularity of noodles has been attributed to its sensory appeal, versatility of form, low cost, ease of preparation at consumers end, nutritional content and long shelf life (Anounye et al., 2012). They are strings or strips of pasta produced through extrusion (Haper and Janson, 2011), using wheat as the major ingredient.

Tensile strength, Extensibility, Elastic recovery, cooking loss, cooking time and percent rehydration are textural characteristics and cooking quality parameters of noodle. They are a critical characteristic, which determines consumer acceptance of the product (Momoh et al., 2020). Tensile testing assesses the breaking strength and the breaking length of cooked noodles. It also gives an indication on how the samples hold together during cooking and reflects the cooking tolerance and cooking quality of noodles (Bhattacharya et al., 1999). Information on these characteristics for rice and African yam beans noodles is scanty, hence this research aims to determine the textural and cooking quality characteristics of noodles prepared from blends of rice, African yam beans and rice bran flours.

2.1. Procurement of Materials

Broken rice grains and rice bran were purchased from Miva Rice Mills, km3, Gboko road, Makurdi, Benue State. Creamed colored African yam bean seeds were purchased from Makurdi Modern Market, Benue State.

2.2. Reagent

Chemical used such as Sodium bicarbonate to facilitate removal of beany off-flavor and dehulling of African yam bean seeds is of analytical grade.

2.3. Equipment

A laboratory scale LSG65 twin screw extruder (Jianansaibaibainuo Technology LMT) with 15.5cm screw length, 10.01cm screw diameter and 0.8mm die diameter was used for extrusion cooking. Extruder, tray drier (M/s Balaji enterprise, Shaharanpur, India) and moisture analyzer (GRD 60H20 China) was used.

2.4. Sample Preparation

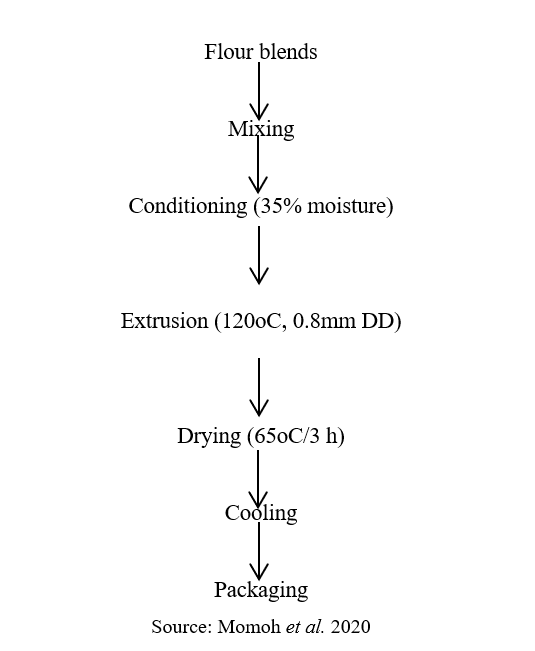

Broken rice grain and rice bran were washed with clean water, oven dried at 45°C for 15 min), they were then ground into flour using laboratory grinder (M/S Sujata: New Delhi India) and sieved through a 0.5mm size mesh and were packaged in Low density polyethylene bags prior to analyses. African yam bean flour was prepared as shown in Figure 1. The flour blend formulation is captured in Table 1. The flour blends were conditioned to 35% moisture content, mixed manually and extruded at 120°C through 0.8 mm die diameter of a laboratory scale twin screw extruder (Jianansaibaibainuo Technology LMT) with 15.5cm screw length, 10.01cm screw diameter.

Extrusion of flour blends was done following the method described by Momoh et al., 2020 for noodle production . Two (2) kilograms of each composite flours were conditioned to 35% moisture content; and kept for 30mins. The composite flours were separately extruded at 120°C barrel temperature. The extruder was stabilized for each run with 2kg whole rice flour at steady state operation; samples were collected in open pans. The extrudate can cool and dried for 3hours in a tray drier at 60°C to a moisture content of 6-8%, sealed in low density polyethylene bags and store in a refrigerator for subsequent analysis. Samples for analyses were milled into flour.

Figure 1. Flow Chart for Preparation of Noodle from Broken rice, AYB and Rice Bran Composite Flour

Table 1. Flour Blends Formulation.

|

|

SAMPLES |

||||

|

A (Control) |

B |

C |

D |

E |

|

|

Broken rice flour |

100 |

92 |

83 |

64 |

46 |

|

African yam beans flour |

0 |

0 |

9 |

28 |

46 |

|

Rice bran flour |

0 |

8 |

8 |

8 |

8 |

2.5. Analytical Methods

Testing for tensile strength was carried out using Tensile Tester (Tinius Olsen HIOKS-5698, Red Hill, England) as described by Bhattacharya et al. (1999). Elastic recovery was determined according to the methods described by Sowbhagya and Ali (2001).Noodle Cooking time, cooking loss and percentage rehydration was done using standard methods as described by AACC, 2010

2.6. Statistical Analysis

Statistical Package for Social Sciences (SPSS) V23 computer software was used to analyze the data. Means and Standard deviation were calculated where appropriate. One way Analysis of variance (ANOVA) was used to determine the treatment that was different from others in the various parameters tested; differences were considered significant at 95% (p<0.05) significant level and 99% (p<0.01) significant level where mentioned.

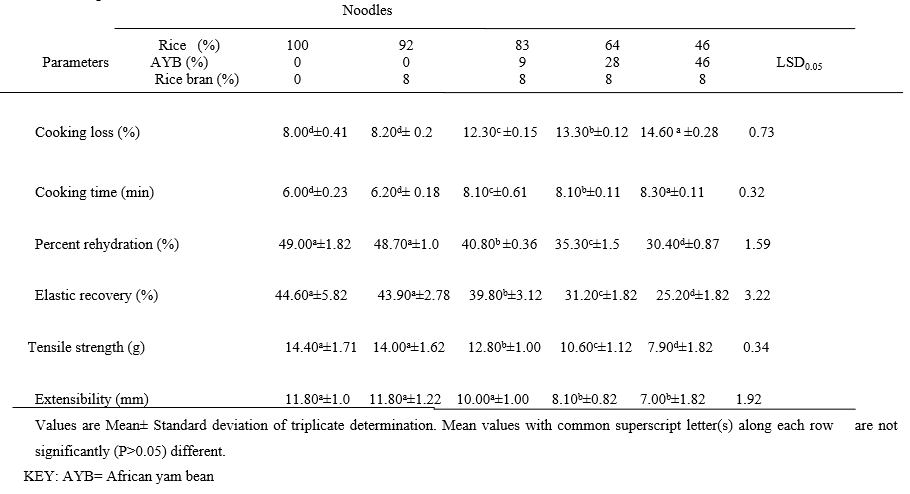

The cooking quality and textural characteristics of noodle produced from rice (R), African yam bean (AYB) and rice bran (B) composite flour is presented in Table 2. Cooking time ranged from 6.0 to 8.3 min with sample 46:46:8R:AYB:B taking the longest time to cook while the control (Rice noodle) cooked fastest. Cooking lose (8.00 -14.60%) increased while percent rehydration (49.00 - 30.40%) decreased with increasing quantity of African yam beans flour in the noodle samples. Rice noodle (Control) had the lowest cooking loss (8.00%) while the highest was recorded for sample formulation 46:46:8R:AYB:B (14.60%), these results were similar to the study by Sajilata et al. (2006), who found that cooking loss value of noodle sample added with banana flour were higher than those of wheat noodles. Cooking loss is an important attribute in noodles as it evaluates the number of irrecoverable solids in cooking water. It is highly vital that the structural integrity of noodles need to be maintained throughout the cooking process. High cooking loss is unacceptable as there can be high amount of solubilized starch present, which leads to cloudy boiling water and “sticky” mouth feel with lower tolerance (Chakraborty et al., 2003; Chen et al., 2002; Jin et al, 1994). Generally, low cooking time for noodle and noodle-like food products is accepted since it is classified as convenient and quick-cooking food. There was significant difference (P<0.05) in means with respect to cooking time of noodles. High rehydration tends to make noodle sticky, whereas low rehydration can render the noodles to be hard with unrefined texture (Collado et al., 2001: Yoenyong-buddhagal and Noomhorm, 2002). The decrease in percent rehydration on addition of African yam beans flour in this study agrees with previous findings (Thomas et al., 2014; Collado et al., 2001; Zhang, 2006) on quality evaluation of ‘flat’ noodle noodles. Tensile strength was high but not significantly (P>0.05) different for 100:0:0R:AYB:B and 100:0:8R:AYB:B (14.40 and 14.00g) respectively and significantly low for 46:46:8R:AYB:B (7.90g). Other noodle samples had dissimilar values for tensile strength. The distance to break the noodle strands is the measure for extensibility (Bhattacharya et al., 1999). The extensibility ranged from 11.80 mm in 100:0:0R:AYB:B to 7.00 mm in 46:46:8R:AYB:B. Noodles prepared from 46:46:8R:AYB:B had the lowest tensile strength and required shorter time to break, which indicates low extensibility. Reduced tensile strength and extensibility were found in noodles with increasing African yam bean flour. Thus, increase in protein reduces tensile strength and extensibility (Bhattacharya et al., 1999). The results indicated that noodles became more difficult to stretch and break with the increase in starch in the noodle. Elastic recovery of noodles was found to reduce with increase addition of African yam bean flour. Noodles with higher firmness and elastic recovery can result in good quality noodles with low cooking loss (Chen et al., 2002).

Table 2: Cooking quality and textural characteristics of cooked noodles prepared from rice, African yam bean and rice bran composite flours

Figure 2. Noodles produced from rice broken rice, bran and AYB.

In conclusion, cooking loss increased as Percent rehydration reduced, flour protein increases cooking time of the noodle, Textural characteristics of cooked noodles reduced with increased flour protein from African yam beans. These properties compared favorably with noodles from wheat and other cereals, hence it could find application in food industries.

AACC, (1995). American Association of Cereal Chemists, Approved methods of the AACC (10th ed.) St. Paul, MN, AACC USA.

Anounye, J. C., Jigam, A. A. and Ndaako, G. M. (2012). Effects of extrusion cooking on the nutrients and anitnutrients composition of pigeon pea and unripe plantain blends. Journal of Applied Pharmaceutical Science, 2(5):58-162.

View ArticleBhattacharya M., Zee S.Y. & Corke H. (1999). Physicochemical properties related to quality of rice noodles. Cereal Chemistry. 76(6): 861-867.

View ArticleChen, Z., Sagis, L., Legger, A., Linssen, J.P.H., Schols, H.A. and Voragen, A.G.J. (2002). Evaluation of starch noodles made from three typical chinese sweet potato starches. Journal of Food science. 67: 3342-3347.

View ArticleCharkraborty, M., Hareland, G. A., Manthey, F.A. and Berglund, L.R.(2003). Evaluating quality of yellow alkaline noodles made from mechanically abraded sprouted wheat. Journal of Science food and Agriculture. 83: 487-495

View ArticleCollado, L.S., Mabesa, L.B., Oates, C.G. and Corke, H. (2001). Bihon-type of noodles from heat-moisture treated sweet potato starch. Journal Food Scence. 66: 604-609.

View ArticleHarper, J. and Janson, R. (2011). Production of nutritious pre-cooked food in developing countries by low-cost extrusion technology. Food Rev Int 1:27-97.

View ArticleMomoh, C. O., Abu, J, O and Yusufu M. I. (2020). Quality Evaluation of Noodles Produced from Broken Rice (Oryza sativa), African Yam Bean (Sphenostylis stenocarpa) and Rice bran composite flours: A tool for Ameliorating PEM in Nigeria. International Journal of Food Engineering and Science, 10(4) 31-38

Okafor, G. I. and Usman, G. O. (2015). Production and evaluation of breakfast cereal from blends of African Yam beans (sphenostylis stenocarpa), Maize(Zea mays), and deffated coconut (cocus Nucifera). Journal of food processing and preservation (in pres). DOI:10.1111/jfpp.12060

View ArticleSajilata, M. G., Singhal, R. S., and Kulkami, P. R. (2006). Resistance starch' A review. Rev. Food Sci., 5:1-16

View ArticleSowbhagya, C. M. and Ali, S. K. (2001). Vermicelli noodles and their quality assessment. Journal of Food Science & Technology 38(5): 423-432

Thomas, Y., Resurreccion, A. P., Juliano, B. O., and Bechtel, D. B. (2014) rice by-products review.Agriculture and Biochemistry., 42, 2015-2023

Jin, M., Wu, J. and Wu, X. A. (1994). Study on the properties of starches used for noodle making. Proceedings of International symposium and exhibition on New approaches in the production of Food Stuffs and intermediate products from Cereal Grains and oil seeds.

Yoenyong-buddhagal, S. and Noomhorm A. (2002). Effect of raw material preparation on rice vermicelli quality. Journal of food science 54(11): 534-539. 54:11<534::AID-STAR534>3.0.CO;2-O

View ArticleZhang, W. (2006). In vitro measurement of resistant starch of cooked milled rice and physiochemical characteristic affecting its formation. Food Chemistry. 105. 462-468

View Article