Yoghurt powder production using microwave–vacuum drier: drying kinetics, mathematical modeling, and characteristics

Corresponding Author

Email: sabbasifood@modares.ac.ir

Affiliation

Abdurrahman Qaderi & Soleiman Abbasi*

Food Colloids and Rheology Lab., Department of Food Science & Technology, Faculty of Agriculture, Tarbiat Modares University, P.O. Box 14115-336, Tehran, Iran

Tel +98-21-48292321, Fax +98-21-48292200

Article Reviewed By:

Dibyakanta Seth(dibya05@tezu.ernet.in)

Citation

Soleiman Abbasi, Yoghurt powder production using microwave

Abstract

Drying behavior of fat-free yoghurt was studied and modeled at various microwave powers (MWP), absolute pressures, and thicknesses in a microwave–vacuum drier (MVD). Then some quality properties of powders were compared with one prepared by commercial freeze drier (FD). The results showed the drying time of MVD was 80% shorter than FD, while in terms of properties, except for color and bulk density, no significant differences were seen. Furthermore, any change of absolute pressure at constant MWP did not affect the drying time whilst any variation in MWP and thickness showed a significant impact on drying time. Moreover, Logistic and Midilli et al. models showed the highest fitting which can be used for prediction purposes. Effective moisture diffusivity of yoghurt was over the range of 4.426×10-10 – 2.831×10-9 m2/s. The activation energy for drying at the absolute pressures of 600 and 800 mbar was about 2.908 and 2.934 W/g, respectively.

Keywords: Yoghurt; Microwave; Freeze drying; Thin layer drying; Modeling

Introduction

Yoghurt is one of the fermented dairy products which can be produced by lactic acid fermentation of milk by S. thermophilus and L. bulgaricus (Tamime and Robinson, 2007). The high nutritional values as well as the favorable effects of starter bacteria are the main influencing parameters for the rapid growing of consumption and popularity of yoghurt (Hamann and Marth, 1984). In addition, yoghurt is significantly more nutritious than the milk from which it is made, owing to high concentration and increased digestibility of protein, lactose, and fat (Sarkar and Misra, 2002) as well as higher calcium, magnesium, phosphor and B vitamins content (Tamime and Robinson, 2007).

Despite all these benefits, the shelf-life of yoghurt in its natural state is very limited i.e., 1 day at ambient temperature (25–35°C), 5 days at 7°C (Kumar and Mishra, 2004),10 days at 4°C (Hayaloglu et al., 2007). The limited shelf-life as well as handling problems prevent its commercialization as well as wide utilization. Therefore, in order to extend its shelf-life some alternative processes such as drying, freezing, pasteurization, etc are used. One of the best and oldest methods is drying. In this technique, by lowering the water content, the product earns an extended shelf-life without the need for refrigeration. Moreover, the volume reduction can decrease the packaging, storage and transportation costs as well (Hayaloglu et al., 2007). Furthermore, owing to nutritional value and special flavor, the yoghurt powder can be potentially used in labaneh and starter culture (Tamime and Robinson, 2007), confectionery, bakery, wafers, chocolates, candies, dips, sauces and cheeses (Hayaloglu et al., 2007) as well as for production of instant yoghurt (Cajigas, 1981). In addition, because of its therapeutic value, more products are being developed (Sharma and Arora, 1995).

Generally speaking, freeze, spray, microwave, vacuum or convective drying can be potentially used for producing yoghurt powder. Although, freeze drying is the highly recommended method for heat-sensitive materials such as yoghurt but its high costs and long processing time have limited this method for high added-value products (Tao et al., 2005). As a result, in the recent years there has been an increasing interest in microwave–vacuum drying (MVD) as potential alternative for freeze drying (Abbasi and Azari, 2009; Ghaderi, Abbasi and Hamidi, 2010; Esmaeilzadeh Nasiri and Abbasi, 2016). This method has advantages of both microwave and vacuum dryings; therefore it can enhance both the energy efficiency and the quality of product. Moreover, other advantages of MVD include the absence of oxygen in the environment, decrease unwanted reactions and time saving. It should also be noted that in conventional heating methods, energy is transported to the food through conduction, convection and radiation but in MVD, heat is generated by direct transforming of the electromagnetic energy into kinetic molecular energy, so the heat is produced deep within the material to be dried (Venkatesh and Raghavan, 2004).

There has been comprehensive studies on MVD of onion (Abbasi and Azari, 2009), carrot (Cui et al., 2004a), lactose (McMinn, 2004, 2006), mushroom (Giri and Parsard, 2006).

Despite extensive researches on MVD, only a few records were found on dairy products particularly on yoghurt (Kim and bhowmik, 1994; 1995; Jaya, 2009; Ghaderi, Abbasi and Hamidi, 2010). Therefore, due to the lack of information as well as the potential benefits of MVD, in the present study the effect of microwave output power, thickness of yoghurt layer, and vacuum level on the drying kinetics, the activation energy, and effective moisture diffusivity, as well as drying model were investigated. Furthermore, the effects of drying conditions (MVD and commercial freeze drying) on some physical properties (color, solubility index, bulk density, despersibilty) of yoghurt powder were compared.

Materials & Methods

2.1. Materials

Fat-free milk was provided by Pak Dairy Co (Tehran, Iran). Its moisture and fat contents were 8.30 (kg water per kg dry matter) and 0.25%, respectively. The fat-free yoghurt was made at the lab scale (Remeuf et al., 2003) and kept at -18°C to prevent any unwanted changes prior to drying

2.2. Microwave–vacuum drier

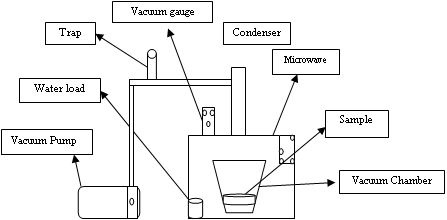

The MVD, designed in our laboratory, was consisted of a modified microwave oven (Micromat 725, 27 L, 0.36m×0.33m×0.23m, 2.45 GHz, AEG, Germany) with variable power output settings (120, 360, 600, 840 and 1200 W), a glass desiccator (I.D. = 150 mm) embedded inside the microwave cavity as a vacuum chamber, vacuum pump, vapor cooling system as well as a digital vacuum gauge (VT1 NP, Italy). The rotation speed of the desiccator was set at 12 rpm (Fig 1). (Abbasi and Azari, 2009). A water load (»80 g water in a Pyrex beaker) was used to protect the magnetron from overheating by standing waves when the product moisture was low, especially during the latter stages of drying (McMinn et al., 2006).

2.3. Measuring the output power of microwave

Microwave ovens are usually classified according to their nominal powers. In general, actual microwave output power is not the same as the nominal one due to diverse reasons. When the magnetron ages, the filament requires more time to reach radiation conditions. In addition, if the magnetron works for a long time, power changes may occur because the long time heating of the permanent magnet weakens the magnetic field, and this will in turn decrease voltage and output power. Therefore, measuring the microwave output power and assuring the constant output power is necessary. To determine the output power, the Schiffman standard method was used (Cui et al., 2004b). Based on this method, temperature increase of a definite mass of water (e.g. 1000 g) for a definite period of time was measured. Then the amount of absorbed energy by the water per unit time calculated by the following equation (eq. 1):

Q abs= Q =mCp∆T/t (1)

where Q = microwave output power in magnetrons (W), Qabs = energy absorbed by sample per unit time (W), m = mass of sample (kg), Cp = specific heat capacity of sample (J/kg°K), ΔT = temperature rise in sample (°K), t = microwave heating time (s) (Cui et al, 2004b).

Each measurement was performed in triplicate and mean ± standard deviation was reported. In the present study, the output power for nominal 10% (120W), 30% (360W) and 50% (600W) powers were 35 ± 2.2, 130 ± 4.5 and 260 ± 5.3 W, respectively.

2.4. Microwave–vacuum drying of yoghurt

For doing so, fat-free yoghurt (50 g) was poured in a glass plate (id=130 mm, covered by polytetrafluoroethylene or Teflon) at various thicknesses (2.2, 4.2, 6.2 mm) and drying conducted at different drying conditions until the moisture content reduced to about 0.05 (kg water per kg dry matter). The moisture loss was determined by a digital balance (Tecator, Model 610, accuracy=0.0001 g, France) at different time intervals (every 3 min for first 30 min, every 5 min for latter 20 min, and every 10 min for any drying time above 50 min). The drying experiments methods are depicted as below:

- C0: combination of absolute pressure (60±5, 200±10, 400±10, 600±10, and 800±10 mbars), microwave output power (35, 130 and 260 W), and the thickness of yoghurt layer (2.2, 4.2, 6.2 mm);

- C1: in order to investigate the effect of freezing, the fat-free yoghurt was frozen at -18°C for 24h and the frozen yoghurt was then dried (35W, 200 mbar, 2.2 mm);

- C2: constant power = 130W and variable absolute pressures (9 min at 400 mbar, 3 min at 600 mbar, 3 min at 400 mbar, and rest of the time at 200 mbar) until the drying ended;

- C3: constant absolute pressure = 200 mbar and variable powers (3 min at 130W, 18 min at 35 W, 3 min at 130 W, 3 min at 35 W and rest of the time at 130 W) until the drying ended.

2.5. Commercial freeze drier

The fat-free yoghurt (2.2 mm) frozen by liquid nitrogen and kept at -18°C for 24h, was placed inside commercial freeze-dryer chamber (Scanvac Freeze Dryer model 55-9 Coolsafe, Denmark), and dried (absolute pressure 0.005 mbar, ambient temperature) for 12 h.

2.6. Measuring the physical properties

The solubility index, dispersibility and bulk density of yoghurt powders were measured using some common methods (Wright et al., 2009). The color indices were also measured by a Hunter lab (Colorflex, A60-1005-654 45/0 model colormeter, Reston, VA, USA) calibrated against standard black and white plates. For each measurement, 5 g of yoghurt powder was placed inside the cup and the color parameters namely a* (green to red), b* (blue to yellow) and L* (black to white) were recorded. Total color difference (ΔE) was calculated using following equation, where subscript “0” refers to the color reading of white plate. White plate was used as the reference and a larger ΔE denoted the greater color change from the reference material.

∆E=√(L0 - L)2 + (a0 -a)2 + (b0 - b)2 (2 )

Browning index (BI) represents the purity of brown color and is considered as an important parameter associated with browning (Lopez-malo et al., 1998) was calculated using following equation, where x= (a*+1.75L*) / (5.645L* + a* – 3.012b*)

BI= [100(x-0.31)]/0.172 (3 )

2.7. Mathematical modeling

For modeling the thin layer drying of yoghurt, the moisture content of different treatments was converted to the moisture ratio (MR) using following equation:

MR = Mt – Me/M0 - Me (4)

where MR is moisture ratio (dimensionless), Mt the mean moisture content of yoghurt at each time (kg water/kg solids), M0 the initial moisture content of yoghurt (kg water/kg solids), and Me stands for the equilibrium moisture content of yoghurt (kg water/kg solids). Since the Me was equal to zero for the microwave drier therefore, the equation simplified as follows (Ozbek and Dadali, 2007; Doymaz, 2005):

MR = M / M0 (5)

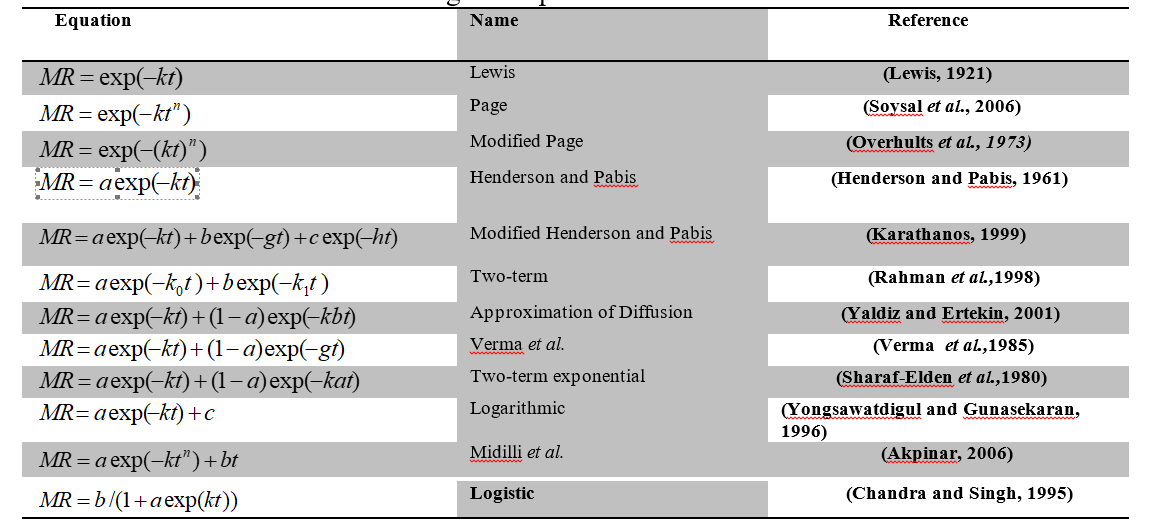

The existing thin layer drying models (Table 1) were fitted to the experimental drying curves (MR versus time) and three criteria {determination coefficient ( ), reduced chi-square ( ) and root mean square error ( )} were adopted to evaluate their appropriateness.

2.8. Statistical analysis

All experiments were repeated at least three times and results were reported as average. Nonlinear fitting procedures for analysis were determined using the curve fitting toolbox (cftool) of the MATLAB software (version 6.1.). Also, analysis of variance (ANOVA) of data was performed using a SPSS, and determination of significant differences (confidence level 95% or p<0.05) of means was carried out by Duncan test.

Results

3.1. Influence of microwave power, chamber pressure, and thickness

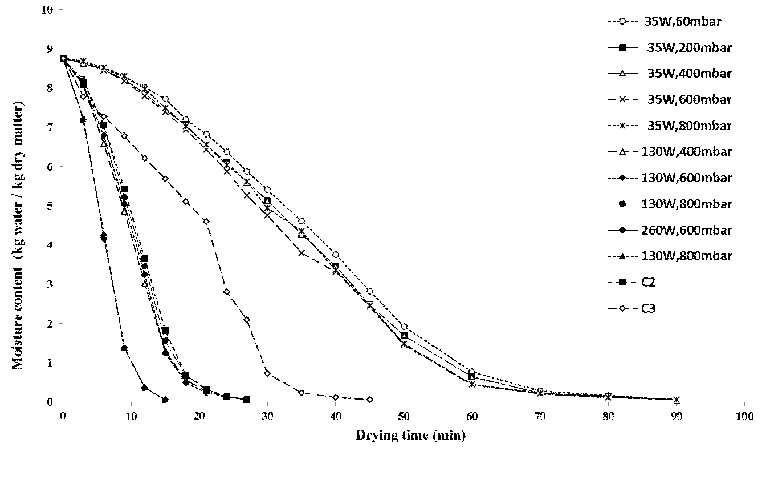

The time required for yoghurt drying using microwave–vacuum drier at various combinations (C0, C1, C2, and C3) presented in Figure 2. As can be seen, the absolute pressure level had no significant effect on drying time, and no difference was observed for different pressures at the same powers, while the microwave power had an important role in time reduction where an increase in power from 35 to 130 and 260W decreased the drying time by 70% and 84%, respectively. It should be noted that the time required for yoghurt drying using commercial freeze drier (390 min) was 4.5, 14.5 and 26 folds of the time needed in microwave–vacuum drier (35, 130 and 260W powers), respectively. These observations strongly confirm the effect of combination of power and pressure as well as the effectiveness of microwave–vacuum drier in considerable decrease of yoghurt drying time compared to freeze drier.

As can be seen (Fig 2), at constant microwave powers (35, 130, and 260 W), the drying rates were also constant and despite any decrease in absolute pressure level, no visible changes were seen. These results can be attributed to the thickness of food sample in drying process. In thin samples (3 to 5mm), drying rate is controlled by energy dissipation rate, while in thick samples (3 to 4cm) drying rate is controlled by moisture diffusion and is therefore affected by system pressure as lower pressure causing faster drying due to higher pressure gradient (Cui et al., 2004b). In general, the slope of drying curves sharply increased for all pressure levels after few minutes. This phenomenon was probably due to the fact that microwave power was not capable of rapid water evaporation, so that the first few minutes were spent for increasing its temperature, during which the amount of evaporated water was not significant. Afterwards, the drying process was accelerated and moisture content reduced from 8.75 to 0.05 (kg water / kg dry matter). Similar trends were seen for C1 and C2 conditions. These treatments (C1 and C2) confirmed that microwave power is more efficient than chamber pressure in reduction of drying time. Curve C2 also shows that changing the power level during drying process has considerable effect on energy consumption as well as drying time. These findings showed a reasonable consistent with the literature (Abbasi and Azari, 2009; Cui et al., 2004b; Ozbek and Dadali, 2007).

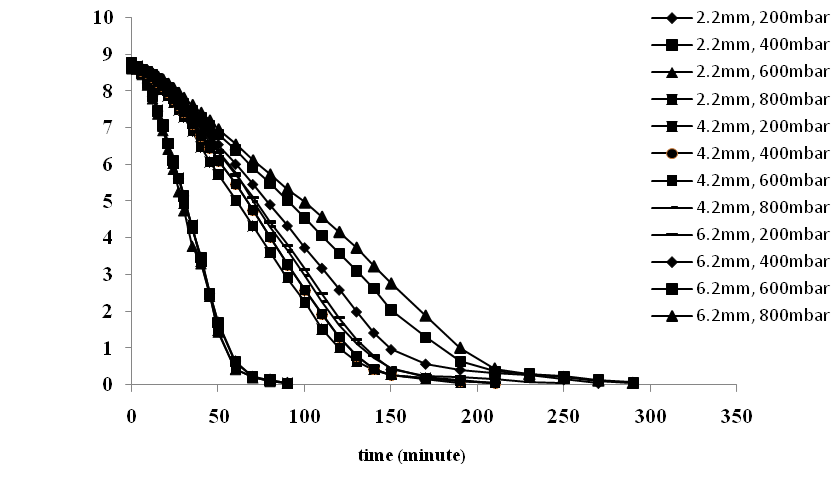

In terms of the effect of the thickness on drying rate (at 35 W), it was found that (Fig 3) by increasing the thickness from 2.2 to 4.2 and 4.2 to 6.2mm the drying time increased about 122% and 40%, respectively. Generally speaking, with increasing thickness of 2.2 to mm drying time increased as at higher thicknesses the impact of moisture diffusion was more vital than energy dissipation rate. These results were consistent with other reports (Abbasi and Azari, 2009; Pappas et al., 1999; Wang and Xi, 2005; Giri and Prasad, 2007). It should be noted that changing the chamber pressure induced some differences on drying rate but not significant (p> 0.05). At higher thickness, lowering the absolute pressure increased the drying rate possibly due to greater pressure gradient. These findings also showed that besides the microwave power, chamber pressure, in drying process the thickness must be considered as well.

3.2. Fitting of experimental data with mathematical models

The moisture ratio (MR) of fat-free yoghurts (initial moisture content 89.75%) at different chamber pressures, microwave powers and thicknesses as well as their drying curves were fitted with 12 existing mathematical models (Table 2). Based on the highest R2 (determination coefficient) and lowest χ2 (reduced chi square) and RMSE (root mean square error) values, the Logistic, Midilli et al, Page and modified Page models were selected as the most fitted ones whereas the diffusion approximation model was the worst one. In line with our findings, in a recent report, Hayolglu and coworkers reported the Midilli et al model as the most suitable one for hot air drying kinetics of the strained yoghurt (Hayaloglu et al., 2007).

3.3. Influence of drying conditions on some characteristics of yoghurt powder

After chopping and pulverizing the dried thin layers of fat-free yoghurt, yoghurt powder was obtained. The size of powders was over the range 63–177 microns and classified as fine powder based on British pharmacology standards. In addition, the dry matter content of powders was about 94.9 ± 0.2% which was in the standard range specified by codex Alimentarius (maximum 5%).

The value of titrable acidity of yoghurt powders dried using microwave–vacuum drier, freeze drier as well as fresh yoghurt (before drying) was about 9.27– 10.06 g per lactic acid in 100 g of dry matter. Statistical analysis also showed that microwave energy (electromagnetic waves) caused no significant effect on this parameter (p<0.05).

With taking into account the initial fat content (0.25%) and drying level, it seems that this parameter did not change during the drying process (p<0.05) and it was about 2.5% in the powders.

According to data obtained from the colorimeter and comparison of different drying treatments in terms of total color difference and browning indices, it was found that the powder produced by commercial freeze drier was significantly different from powders dried by microwave–vacuum drier (Table 3). As can be seen, the powder obtained by freeze drier and one dried by microwave–vacuum drier (35W, 60 mbar ) had the lowest total color difference and significantly differed with the other treatments (p<0.05). In addition, the color difference of all powders produced by microwave–vacuum drier had significant difference with each other, where those treated at 35 W microwave power at any absolute pressure levels had the highest similarity with one prepared by commercial freeze drier.

The browning index of all treatments lied over the range 5–23. This index shows purity of brown color and is reported as an important indicator of the processes in which enzymatic and non-enzymatic browning occur. The high value of this index is not favorable and the higher the value, the darker the color of produced powder. It is likely why that the browning index of powders dried by microwave–vacuum drier particularly at higher microwave powers was much higher than those treated by freeze drier (ambient temperature), or at 35 W and 60 mbar (about 36°C). It seems that due to simultaneous presence of protein and lactose, Millard reaction occurred where at higher microwave powers this reaction was more intense leading to higher browning index (Cui et al., 2004a). It has been reported that browning rate increases 2 to 3 times by 10°C temperature increase. It is worth noting that the Millard reaction although has the highest rate at higher water activity (0.6 and 0.7) but since in the last stages of drying the water activity is much less than this range, therefore the browning index does not go too far (Nursten, 2005).

Solubility index is an important variable in food powders. Low solubility normally causes processing difficulties and economic loss as the milk solids may be lost as insoluble materials. This index for all the fat-free yoghurt powders was in the range 16.6–17.5 ml, and there was no significant difference between treatments (Table 3). The higher the solubility index, the lower the solubility of the powder. According to documented standards, no particular standard was found in relation to a permitted range of solubility index in yoghurt powder, but ADPI (American Dairy Products Institute) has reported maximum permitted value (15 ml) for drum dried milk powder which is very close to our results. It has been reported that Millard reaction and lactic acid content can potentially be reasons for the increase of solubility index (Sithole et al., 2006; Wright et al., 2009), but it can be emphasized that at least based on our observations in freeze drier this reaction has not occurred but its solubility index was also similar to other treatments; therefore, this parameters cannot be regarded as important factors in this study.

The volume density of microwave–vacuum dried powders (740 kg/m3) was significantly different (P < 0.05) than one produced by freeze drier (380 kg/m3). These figures were nearly similar to the results of other researchers (Sharma and Arora, 1995; Kumar and Mishra, 2004). Moreover, the powders produced by microwave–vacuum drier at various conditions were very similar probably due to thinness of yoghurt layer during drying. Due to low thickness there was probably less porosity in powders produced in different pressures, and the density was the same for all of them. While in freeze drier, because of water conversion from ice to vapor by sublimation, the dried matter texture was porous and this in turn was effective on volume density (Oikonomopoulou et al., 2011).

Dispersion property is defined as decomposition of powder to particles in the liquid (Wright et al., 2009). Therefore, high dispersible powders need less time or force to disperse in liquid relative to low dispersible ones. In the present study, the dispersion property was adversely related to the number of times needed to shake. Therefore, the powder requiring less shaking had higher dispersibility. Dispersion property for powders obtained with both methods was 70±25 similar to results obtained by Shaker et al. (1999).

The effect of fat-free yoghurt thickness on titrable acidity, fat, solubility index and dispersibility was not significant, while it showed significant effect (P < 0.05) on color and density (Table 4). The average bulk density for 2.2, 4.2 and 6.2 mm thicknesses was 740, 624 and 633kg/m3, respectively. These were consistent with results of other researchers (Kumar and Mishra, 2004). For any constant thickness, different chamber pressures did not induce any significant changes on this property. It can be possibly due to the low thickness of yoghurt which was not enough to create puffed structure whilst this phenomenon can usually happen at relatively higher thicknesses (e.g. 3–5 cm). In general, the characteristics of powder obtained at 200 mbar, 35W (4.2 mm) was very close to one obtained from 2.2 mm (60mbar and 35W).

3.4. Calculation of effective moisture diffusivity

In order to calculate effective moisture diffusion coefficient, the fat-free yoghurt drying operation continued until no apparent weight difference was observed between the two successive weightings. Then the moisture ratio (MR) was calculated using equation 5. By plotting ln (MR) versus drying time and finding the slope of linear part, the effective moisture diffusion (Deff) calculated using equation 8 (Table 4).

The effective diffusivity coefficient of fat-free yoghurt is calculated using the simplified mathematical Fick’s second model. Analytical solution of Fick’s diffusion equation is given in Eq. 6 for an infinite slab (Singh and Heldman, 2001).

MR(t) = M(t)-Me / M0-Me = 8/π2 ∑n=1 1/(2n-1)2 exp [-π2(2n-1)2/4 Deff t/a2] (6 )

where Deff is the effective diffusivity coefficient (m2/s); L is the half thickness of the slab (m) and n is the positive integer. For long drying period, the above equation can be simplified. Eq. 7 is obtained by taking the natural logarithm of both sides.

ln(MR)= ln(8/π2)( π2 Defft/4a2) (7)

The effective moisture diffusivity was calculated using the method of slopes. Effective diffusivities are typically determined by plotting experimental drying data in terms of ln (MR) versus time gives a straight line with a slope of k0:

π2 Defft/4a2 (8)

For fat-free yoghurt, this coefficient varied from 4.42×10-10 to 2.83×10-9m2/s for different conditions. Deff generally increased with increase of microwave power (e.g. in constant pressure of 600 mbar) and thickness of samples, whereas any change in chamber pressure (e.g. in constant power of 130W) had no effect on this coefficient. In line with our results, the effective diffusion coefficient for strained yoghurt in hot air drier was reported over the range of 9.5×10-10 to 1.3×10-9 (Hayaloglu et al., 2007). In general, the effective diffusion coefficients for the food system are on the order of 10-8–10-12 m2/s (Wam and Tra, 1997).

3.5. Activation Energy

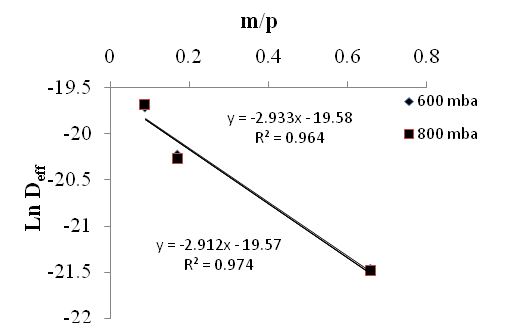

The activation energy was calculated by plotting ln (Deff) versus m/p (Fig 4). Generally speaking, at least three points are required to plot this diagram, therefore in this survey only for two chamber pressures (600 and 800 mbar) and 3 microwave powers (35, 135 and 260 W) was used for calculation of activation energy. The calculated activation energy for these pressure levels was nearly 2.9 W/g which indicates no significant effect of this variable on activation energy. No similar research was found to be compared with.

Conclusion

This study, amongst the few investigations conducted on the possibility of yoghurt powder production using microwave–vacuum drier, confirmed the possibility as well as the advantages of this technique over the commercial freeze drier. In addition, the impact of microwave power was much pronounced than chamber pressure. According to factors measured, the 60 mbar pressure, 35W power, 2.2 mm as well as 200 mbar pressure, 35W power, 4.2 mm treatments had highest similarity with one dried by freeze drier at reasonably (80%) shorter time. The results of this study also showed that the drying of yoghurt can be accurately predicted using Logistic or Midilli et al. models. It is noteworthy that yoghurt powder is almost a new foodstuff and more research is needed to be done on optimization of its drying process. As a result, it can be concluded that the microwave–vacuum drier can be considered as an excellent alternative for existing and expensive freeze driers.

Images and Tables

|

Statistical Models parameters |

Microwave power (W) |

C1 |

C2 |

||||||||||

|

35 |

130 |

260 |

|||||||||||

|

Chamber absolute pressure (mbar) |

|||||||||||||

|

60 |

200 |

400 |

600 |

800 |

400 |

600 |

800 |

600 |

800 |

||||

|

Page |

R2 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.97 |

|

χ2 |

0.00026 |

0.00026 |

0.00026 |

0.00029 |

0.0003 |

0.0002 |

0.0003 |

0.00017 |

0.00021 |

0.00040 |

0.00029 |

0.00443 |

|

|

RMSE |

0.01615 |

0.01626 |

0.01634 |

0.01706 |

0.01888 |

0.01455 |

0.01967 |

0.01333 |

0.01461 |

0.02018 |

0.01703 |

0.0666 |

|

|

Modified Page |

R2 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.96 |

|

χ2 |

0.000261 |

0.00026 |

0.00026 |

0.00029 |

0.00035 |

0.00021 |

0.00038 |

0.000177 |

0.00021 |

0.0004 |

0.00029 |

0.00443 |

|

|

RMSE |

0.01615 |

0.01626 |

0.01634 |

0.01706 |

0.01888 |

0.01455 |

0.01967 |

0.01333 |

0.01461 |

0.02018 |

0.01703 |

0.0666 |

|

|

Henderson and Pabis |

R2 |

0.92 |

0.93 |

0.93 |

0.93 |

0.93 |

0.93 |

0.92 |

0.92 |

0.92 |

0.91 |

0.91 |

0.89 |

|

χ2 |

0.01089 |

0.00974 |

0.00976 |

0.0091 |

0.01041 |

0.01244 |

0.01461 |

0.01488 |

0.01696 |

0.01921 |

0.01537 |

0.01422 |

|

|

RMSE |

0.1043 |

0.09869 |

0.09877 |

0.09536 |

0.102 |

0.1115 |

0.1209 |

0.122 |

0.1303 |

0.1386 |

0.124 |

0.1193 |

|

|

Logarithmic |

R2 |

0.92 |

0.93 |

0.93 |

0.93 |

0.93 |

0.93 |

0.92 |

0.92 |

0.92 |

0.91 |

0.91 |

0.89 |

|

χ2 |

0.01088 |

0.00974 |

0.00975 |

0.00909 |

0.01041 |

0.01244 |

0.01461 |

0.0148 |

0.0169 |

0.01921 |

0.0153 |

0.0142 |

|

|

RMSE |

0.1043 |

0.09869 |

0.09877 |

0.09536 |

0.102 |

0.1115 |

0.1209 |

0.122 |

0.1303 |

0.1386 |

0.124 |

0.1193 |

|

|

Two term |

R2 |

0.92 |

0.93 |

0.93 |

0.93 |

0.92 |

0.92 |

0.92 |

0.92 |

0.92 |

0.91 |

0.91 |

0.89 |

|

χ2 |

0.01156 |

0.01035 |

0.01036 |

0.0096 |

0.0110 |

0.0142 |

0.0167 |

0.0170 |

0.02262 |

0.02562 |

0.01757 |

0.0155 |

|

|

RMSE |

0.1076 |

0.1017 |

0.1018 |

0.09829 |

0.1052 |

0.1192 |

0.1292 |

0.1305 |

0.1504 |

0.1601 |

0.1326 |

0.1246 |

|

|

Approximate of diffusion |

R2 |

0.87 |

0.89 |

0.89 |

0.90 |

0.89 |

0.91 |

0.89 |

0.89 |

0.91 |

0.96 |

0.89 |

0.88 |

|

χ2 |

0.01780 |

0.01598 |

0.016 |

0.01515 |

0.0173 |

0.0180 |

0.021 |

0.02181 |

0.02561 |

0.01071 |

0.02228 |

0.01778 |

|

|

RMSE |

0.1334 |

0.1264 |

0.1265 |

0.1231 |

0.1316 |

0.1344 |

0.1449 |

0.1477 |

0.16 |

0.1035 |

0.1493 |

0.1333 |

|

|

Verma et al |

R2 |

0.98 |

0.99 |

0.89 |

0.90 |

0.89 |

0.91 |

0.89 |

0.89 |

0.91 |

0.90 |

0.89 |

0.88 |

|

χ2 |

0.0021 |

0.00185 |

0.016 |

0.0151 |

0.0173 |

0.018 |

0.021 |

0.0218 |

0.0253 |

0.0289 |

0.0221 |

0.0171 |

|

|

RMSE |

0.04631 |

0.04288 |

0.1265 |

0.1231 |

0.1316 |

0.1344 |

0.1449 |

0.1477 |

0.16 |

0.1703 |

0.1493 |

0.1333 |

|

|

Modified Henderson and Pabis |

R2 |

0.92 |

0.93 |

0.93 |

0.93 |

0.93 |

0.93 |

0.92 |

0.92 |

0.92 |

0.91 |

0.91 |

0.89 |

|

χ2 |

0.0123 |

0.011 |

0.0109 |

0.0106 |

0.0118 |

0.0166 |

0.0194 |

0.0198 |

0.0339 |

0.0384 |

0.0205 |

0.0170 |

|

|

RMSE |

0.1111 |

0.1051 |

0.1015 |

0.1151 |

0.1086 |

0.1288 |

0.1396 |

0.1409 |

0.1842 |

0.196 |

0.1432 |

0.1306 |

|

|

Two-term exponential |

R2 |

0.98 |

0.98 |

0.98 |

0.99 |

0.98 |

0.99 |

0.98 |

0.98 |

0.99 |

0.98 |

0.98 |

0.94 |

|

χ2 |

0.0026 |

0.0022 |

0.0022 |

0.0019 |

0.0024 |

0.0024 |

0.0034 |

0.0031 |

0.0022 |

0.0034 |

0.0037 |

0.0078 |

|

|

RMSE |

0.9218 |

0.9301 |

0.9301 |

0.9311 |

0.9275 |

0.9287 |

0.9185 |

0.9169 |

0.9235 |

0.9146 |

0.9137 |

0.8952 |

|

|

Midilli et al |

R2 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.98 |

|

χ2 |

0.0002 |

0.0002 |

0.0002 |

0.00027 |

0.00034 |

0.00024 |

0.0004 |

0.00019 |

0.00026 |

0.00048 |

0.00024 |

0.0028 |

|

|

RMSE |

0.01432 |

0.01448 |

0.01456 |

0.01665 |

0.01854 |

0.01568 |

0.02083 |

0.01408 |

0.01635 |

0.02202 |

0.0157 |

0.0538 |

|

|

Wang and Singh |

R2 |

0.96 |

0.96 |

0.96 |

0.96 |

0.96 |

0.97 |

0.96 |

0.96 |

0.97 |

0.97 |

0.96 |

0.96 |

|

χ2 |

0.0057 |

0.0053 |

0.0053 |

0.0052 |

0.0062 |

0.0058 |

0.0072 |

0.0073 |

0.0066 |

0.0075 |

0.0071 |

0.0051 |

|

|

RMSE |

0.0761 |

0.073 |

0.0729 |

0.0727 |

0.0792 |

0.076 |

0.0853 |

0.0859 |

0.0818 |

0.08672 |

0.0843 |

0.07178 |

|

|

Logistic |

R2 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.98 |

|

χ2 |

0.00018 |

0.00017 |

0.00017 |

0.0003 |

0.00035 |

0.00014 |

0.00029 |

0.00012 |

0.00010 |

0.00027 |

0.00015 |

0.0025 |

|

|

RMSE |

0.0134 |

0.0131 |

0.0133 |

0.0175 |

0.0187 |

0.012 |

0.017 |

0.010 |

0.010 |

0.0164 |

0.0125 |

0.0506 |

|

|

Drying Conditions |

Solubility Index |

Browning Index |

Total Color Difference

|

|

35W, 60 mbar |

16.8a |

4.87b |

4.25a |

|

35W, 200 mbar |

17.5a |

12.14c |

9.59b |

|

35W, 400 mbar |

17.3a |

13.39d |

10.55c |

|

35W, 600 mbar |

17.5a |

15.11e |

11.77d |

|

35W, 800 mbar |

16.9a |

16.66f |

13.07e |

|

130W, 200 mbar |

17.5a |

20.83h |

15.57g |

|

130W, 400 mbar |

16.9a |

21.62i |

16.2h |

|

130W, 600 mbar |

17.5a |

28.01k |

19.99j |

|

130W, 800 mbar |

17.6a |

28.71l |

20.45k |

|

260W, 400 mbar |

17.6a |

24.5j |

17.9i |

|

260W, 600 mbar |

16.8a |

24.83j |

18.06i |

|

260W, 800 mbar |

16.9a |

30.94m |

21.96l |

|

C1 |

17.3a |

12.06c |

9.48b |

|

C2 |

16.9a |

21.76i |

16.09h |

|

C3 |

17.6a |

19.85g |

15.01f |

|

Commercial Freeze drying |

16.6a |

1.21a |

4.14a |

References

Abbasi, S. and Azari, S. (2009). Novel microwave-freeze drying of onion slices. International Journal of Food Science & Technology, 44: 974?979.

View ArticleAkpinar, E. K. (2006). Determination of suitable thin layer drying curve model for some vegetables and fruits. Journal of Food Engineering, 73: 75?84.

View ArticleCajigas, S. D. (1981). Instant yoghurt composition, United States Patent 4, 289 788.

Chandra, P. K. and Singh R. P. (1995). Applied Numerical Methods for Food and Agricultural Engineers. CRC Press, Boca Raton, FL pp. 163?167.

Cui, Z. W., Xu, S. Y., and Sun, D. W. (2004a). Effect of microwave?vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Drying Technology, 22: 563?565.

View ArticleCui, Z. W., Xu, S. Y. and Sun, D. W. (2004b). Microwave?vacuum drying kinetics of carrot slices. Journal of Food Engineering, 65: 157?164.

View ArticleDoymaz, I. (2005). Influence of pretreatment solution on the drying of sour cherry. Journal of Food Engineering, 78: 591?596.

View ArticleEsmaeilzadeh Nasiri, M, and Abbasi, S. (2016). Effect of hydrocolloids and drying conditions on stability, rheological and sensoryp of reconstituted yoghurt (Instant Yoghurt). Focusing on Modern Food Industry (FMFI), 5: 6?15.

View ArticleGhaderi, A., Abbasi, S., and Hamidi, Z. (2010). Yoghurt powder production using a microwave?vacuum drier. Iranian Food Science and Technology Research Journal, 6 (3): 210?222

Giri, S.K. and Prasad, S. (2007). Drying kinetics and rehydration characteristics of microwave?vacuum and convective hot-air dried mushrooms. Journal of Food Engineering, 78: 512?521.

View ArticleHamann, W.T. and Marth, E. H. (1984). Survival of Streptococcus thermophilus and Lactobacillus bulgaricus in commercial and experimental yogurts. Journal of Food Protection, 47: 781?786.

View ArticleHayaloglu, A. A., Karabulut, I., Alpaslan M. and Kelbaliyev, G. (2007). Mathematical modeling of drying characteristics of strained yoghurt in a convective type tray-dryer. Journal of Food Engineering, 78: 109?117.

View ArticleHenderson, S. M. and Pabis, S. (1961). Grain drying theory I: temperature effect on drying coefficient. Journal of Agriculture Research Engineering, 6: 169?174.

Jaya, S. (2009). Microstructure analysis of dried yogurt: Effect of different drying methods. International Journal of Food Properties, 12: 469?481.

View ArticleKarathanos, V. T. (1999). Determination of water content of dried fruits by drying kinetics. Journal of Food Engineering, 39: 337?344. 00132-0

View ArticleKim, S.S., and Bhowmik, S.R. (1994). Moisture sorption isotherms of concentrated yoghurt and microwave?vacuum dried yoghurt powder. Journal of Food Engineering, 21: 157?175. 90184-8

View ArticleKim, S.S., and Bhowmik, S.R. (1995). Effective moisture diffusivity of plain yoghurt undergoing microwave?vacuum drying. Journal of Food Engineering, 24: 137?138. P1614-4

View ArticleKumar, P. and Mishra, H. N. (2004). Yoghurt powder?a review of process technology, storage and utilization. Food and Bioproducts Processing, 82(C2): 133?142.

View ArticleLewis, W. K. (1921). The rate of drying of solid materials. Journal of Industrial Engineering, 13: 427?443.

View ArticleLopez-malo, A., E. Palou, G. V. Barbosa-Canovas, J. Welti-Chanes and B.G. Swanson. (1998). Polyphenoloxidase activity and color changes during storage of high hydrostatic pressure treated avocado puree. Food Research International, 31(8): 549?556. 00028-9

View ArticleMcMinn, W. A. M. (2006). Thin-layer modelling of the convective, microwave, microwave?convective and microwave?vacuum drying of lactose powder. Journal of Food Engineering, 72: 113?123.

View ArticleNursten, H. (2005). The Maillard Reaction, Chemistry, Biochemistry and Implications. Atheneum Press Ltd, Gateshead, Tyne and Wear, UK.

Oikonomopoulou, V. P., Krokida, M. K., & Karathanos, V. T. (2011). The influence of freeze drying conditions on microstructural changes of food products. Procedia food science, 1: 647-654.

View ArticleOverhults, D. G., White, H. E., Hamilton, H. E., and Ross, I. J. (1973). Drying soybeans with heated air. Transactions of American Society of Agricultural Engineers, 16: 112?113.

View ArticleOzbek, B. and Dadali, G. (2007). Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. Journal of Food Engineering, 83: 541?549.

View ArticlePappas, C., Tsami, E. and Marinos-Kouris, D. (1999). The effect of process conditions on the drying kinetics and rehydration characteristics of some microwave?vacuum dehydration fruits. Drying Technology, 17: 157?174.

View ArticleRahman, M. S., Perera, C. O. and Theband, C. (1998). Desorption isotherm and heat pump drying kinetics of peas. Food Research International, 30: 485?491. 00009-X

View ArticleRemeuf, F., Mohammed, S., Sodini, I. and Tissier, J. P. (2003). Preliminary observations on the effects of milk fortification and heating on microstructure and physical properties of stirred yogurt. International Dairy Journal, 13:773?782. 00092-X

View ArticleSarkar, S. and Misra, A. K. (2002). Yoghurt: Nutritional and therapeutic aspects. Indian Journal of Microbiology, 42: 275?287.

Shaker, R. R., Jumah, R. Y., Tashtoush, B. and Zraiy, A. F. (1999). Manufacture of jameed using a spray drying process: a preliminary study. International Journal of Dairy Technology, 52: 77?80.

View ArticleSharaf-Elden, Y. I., Blaisdell, J. L. and Hamdy, M. Y. (1980). A model for ear corn drying. Transactions of American Society of Agricultural Engineers, 23: 1261?1265.

View ArticleSharma, N. K. and Arora, C. P. (1995). Influence of product thickness, chamber pressure and heating conditions on production rate of freeze-dried yoghurt. International Journal of Refrigeration, 18: 297?307. 00025-7

View ArticleSingh, R.P. and Heldman, D.R. (2001). Introduction to Food Engineering, third ed. Academic Press, USA.

Sithole R., Mcdaniel, M. R. and Goddik, L. M. (2006). Physicochemical, microbiological, aroma, and flavor profile of selected commercial sweet whey powders. Journal of Food Science, 71: C157-C163.

View ArticleSoysal, Y., Oztekin, S. and Eren, O. (2006). Microwave drying of parsley: modelling, kinetics, and energy aspects. Biosystems Engineering, 93: 403?413.

View ArticleTamime, A. Y. and Robinson, R. K. (2007). Yoghurt Science and Technology. 3rd ed. Cambridge: Woodhead Publishing Limited and CRC Press LLC, England.

Tao, Z., Wu, H., Chen, G. and Deng, H. (2005). Numerical simulation of conjugate heat and mass transfer process within cylindrical porous media with cylindrical dielectric cores in microwave freeze-drying. International Journal of Heat and Mass Transfer, 48: 561?572.??

View ArticleVenkatesh, M. S. and Raghavan, G. S. V. (2004). An overwiev of microwave processing and dielectric properties of agri-food materials. Biosystems Engineering, 88: 1?18.

View ArticleVerma, L. R., Bucklin, R. A., Endan, J. B. and Wraten, F. T. (1985). Effects of drying air parameters on rice drying models. Transactions of American Society of Agricultural Engineers, 28: 296?301.

View ArticleWam, M. and Tra, M. (1997). Diffusional analysis during air-drying of a starch system, development in chemical engineering. Mineral Proc, 5: 61?77.

Wright, B. J., Zevchak, S. E., Wright, J. M. and Drake, M. A. (2009). The Impact of agglomeration and storage on flavor and flavor stability of whey protein concentrate 80% and whey protein isolate. Journal of Food Science, 74: S17?S29. PMid:19200117

View Article PubMed/NCBIYaldiz, O., & Ertekin, C. (2001). Thin layer solar drying of some vegetables. Drying Technology, 19: 583?597.

View ArticleYongsawatdigul, J. and Gunasekaran, S. (1996). Microwave?vacuum drying of cranberries: Part I: energy use and efficiency. Journal of Food Processing and Preservation, 20: 121?143.

View Article