Cristina García -Viguera

Tel +34 968 396304; fax +34 968 396213;

E-mail: cgviguera@cebas.csic.es

© 2019 Sift Desk Journals. All Rights Reserved

VOLUME: 3 ISSUE: 3

Page No: 318-329

Amadeo Gironés-Vilaplanaa, Rosario Lópezb, Cristina García-Vigueraa*, Paula M. Periagob, c

a CEBAS-CSIC Phytochemistry and Healthy Food Lab. Department of Food Science and Technology, P.O. Box 164, E-30100, Espinardo, Murcia, Spain.

b Departamento de Ingeniería de Alimentos y del Equipamiento Agrícola, Campus de Excelencia Internacional Regional "Campus Mare Nostrum", Universidad Politécnica de Cartagena, Paseo Alfonso XIII 48, 30203 Cartagena, Murcia, Spain.

c Instituto de Biotecnología Vegetal, Campus de Excelencia Internacional Regional ``Campus Mare Nostrum´´. Universidad Politécnica de Cartagena, Spain

Xinyan Wang(wangxyhku@uestc.edu.cn)

Article Under Review

The aim of this work was to determine the effect of different heat treatments ( 1) 90ºC and cooled down immediately to a final temperature of 30ºC, 2) 90ºC during 15s. and immediately cooled down to a final temperature of 30ºC, and 3) commercial treatment) on the colour, pH, total soluble solids, antioxidant capacity, and phenolic compounds of three different vegetal food products: 1.- carrot, orange and coriander soup (COS); 2.- gazpacho (typical Spanish vegetable soup made mainly with tomato, pepper, cucumber, olive oil, vinegar and garlic (GAZ); and 3.- tomato, mint and basil soup (TMS). The results showed that the mentioned parameters were influenced by the heat treatments studied in, depending on the temperature and time of each one, and the different products which were applied. COS and TMB showed the highest antioxidant capacity values in their respective commercial samples. However, GAZ treated at 90ºC and 90ºC/15s. kept the same antioxidant capacity levels that the tank sample (untreated). The colour, pH and total soluble solids parameters remained practically without significant changes produced by the different heat treatments applied, demonstrating that the applied treatments can be more effective than commercial in order to preserve shelf life of these products, and keeping the majority of their crucial properties in these kinds of foods. For that, the results here presented are of significant interest for agro-food industry.

Keywords: Heat treatment, bioactivity, quality, cold soups, vegetables.

Nowadays consumers demand high quality food with natural taste and flavour, healthy and nutritious (Elez-Martínez and Martín-Belloso 2007). The acceptance of these products by consumers depends on that the quality, bioactivity, and sensory characteristics remain at acceptable levels during shelf-life (Gironés-Vilaplana et al. 2013a). Heat treatment is the most common technology to increase the shelf life of fruits and vegetables, by the inactivation of microorganisms and enzymes. However, thermal processing can affect negatively the sensory and nutritional properties of these products (Elez-Martínez and Martín-Belloso 2007), and may lead to a reduction of their antioxidant capacity (Patras et al. 2009b). Natural antioxidants may suffer significant losses as a consequence of the different processes to which they are subjected products (Ma et al. 2013). Furthermore, they become unstable when exposed to heat, light and oxygen during thermal process, so it is considered that processed fruits and vegetables have lower nutritional value than fresh one.

Fruits and vegetables have a vital role in human nutrition as sources of natural antioxidants (Patras et al. 2009b). It has been shown that the consumption of fruits and vegetables is associated with a reduced risk of develop chronic diseases such as cardiovascular disease, cancer, diabetes, and neurodegenerative diseases (Wang et al., 2014), with a high incidence the in Western world. These several human diseases are related or are due to oxidative stress caused by an increment of reactive oxygen species (ROS) in the human body. It has been suggested that antioxidant compounds, especially phenolic compounds present in fruits and vegetables may reduce these oxidative stress caused by ROS (Ćetković et al. 2012). The actions of the phenolic antioxidants include radical scavenging and inhibition of the production of reactive species derived from normal metabolism of cells. Thus, antioxidants may prevent damage to lipids, proteins and nucleic acids and consequent cellular damage (Ćetković et al. 2012); and therefore, many of the chronic diseases above mentioned.

The Mediterranean Diet, rich in fruits and vegetables, can provide the phenolic compounds that help to prevent the above mentioned diseases. Among all vegetables, tomatoes are both qualitatively and quantitatively, an important component of this Mediterranean Diet (either raw or processed into juice or sauce product). As demonstrated in the scientific literature, a diet rich in tomatoes may protect against cardiovascular disease and some cancers (Viuda-Martos et al. 2014). This fact is because tomatoes are low in fat, calories and cholesterol, and rich in vitamin A and C, β-carotene, lycopene and potassium, being also an important source of phenolic compounds in the human diet (Odriozola-Serrano et al. 2008; Vallverdú-Queralt et al. 2011). The main phenolic compounds found in tomato are flavanones (naringenin glycosylated derivatives) and flavonols (quercetin, rutin and glycosylated derivatives of kaempferol) (Vallverdú-Queralt et al. 2011). Gazpacho and other vegetable cold soups are common foods consumed into the Mediterranean Diet, which include tomato and other vegetables (Elez-Martínez and Martín-Belloso 2007). These cold soups incorporate ingredients that offer the opportunity to increase possible health benefits of these vegetables consumption, and improve sensory characteristics. The gazpacho contains mainly tomato, cucumber and pepper, and to a lesser extent olive oil, onion (not always), garlic, vinegar and salt (Elez-Martínez and Martín-Belloso 2007).

Another vegetable considerably used in the Mediterranean Diet for the elaboration of these soups is carrot. Carrots are nutritionally important vegetables: they are rich in antioxidants like vitamin A, C and E and β-carotene and phenolic compounds, and are consumed in different ways: fresh, juices, soups among others (Ma et al. 2013). Accordingly to Ma et al. (2013), the polyphenols and the antioxidant activity in carrot juice remained after processing, demonstrating that carrot juice can serve as a possible source of natural dietary antioxidants in human nutrition and health (Ma et al. 2013).

Therefore, the aim of this study was to determine the effect of different heat treatments on the antioxidant capacity, phenolic compounds and quality parameters of three different food products, highly consumed in the Mediterranean Diet: carrot, orange and coriander soup (COS); gazpacho (GAZ); and tomato, mint and basil soup (TMS); compared with untreated controls and commercial thermal treatment, in order to obtain the necessary information and to recommend to the food industry about the influence of thermal processing on the loss of organoleptic properties, bioactive compounds, and bioactivity.

2.1. Chemicals

2,2-diphenyl-1-picrylhidracyl radical (DPPH•), 2,2-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid)diammonium salt (ABTS˙+), 2,4,6-tripyridyl-S’-triazine (TPTZ), ferric chloride hexahydrate, fluorescein (free acid), 2,2′-azobis(2-methylpropionamidine) dihydrochloride (APPH), monobasic sodium phosphate, dibasic sodium phosphate, Folin Ciocalteu’s Reagent, potassium phosphate, 6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid (Trolox), magnesium chloride hexahydrate, sodium carbonate (anhydrous), sodium benzoate, and potassium sorbate were used in order to carry out all the analysis. Ultrapure water was also produced using a Millipore water purification system.

2.2. Food Products

Three different products made from vegetables were analysed: carrot, orange and coriander cold soup (COS), gazpacho (GAZ), and tomato, mint and basil cold soup (TMB). All products were provided by Tropicana Alvalle®, SL. Company provided product without heat treatment (tank product) and the commercial product already packaged. The tank product consisted of different vegetables washed, peeled, crushed and then seasoned with the other ingredients such as extra virgin olive oil, salt, lemon juice or wine vinegar. Commercial products had the same ingredients, with a commercial pasteurization and packaged in a pure cold-Pak®, keeping it refrigerated throughout their shelf life.

2.2.1. COS

This soup contains water, carrot (35.5%), orange juice (16.6%), onion puree, cream, extra virgin olive oil, sugar, salt, wine vinegar, cilantro (0.2%), bay leaf, thyme and white pepper. The vegetables content was 40% of the final product.

2.2.2. GAZ

This product contains the following ingredients: tomato, pepper, cucumber, onion, extra virgin olive oil (2.6%), water, wine vinegar, salt, garlic and lemon juice. The vegetables content was 93% of the final product.

2.2.3. TMS

This soup containing tomato (87%), zucchini, lemon juice, water, onion, extra virgin olive oil, basil (0.7%), garlic, salt, mint (0.2%) and white pepper. The vegetables content was 93% of the final product.

2.3. Thermal treatments to tank products

Thermal treatments were carried out in a thermoresistometer Mastia (Conesa et al. 2009). The vessel of the instrument was sterilized before the treatments, and then filled with 400 ml of the food products. All treatments started at a temperature of 30ºC. For the first treatment (A) the thermoresistometer was programmed to reach a final temperature of 90ºC with a heating rate of 30 ºC/min, and when the sample reached the final temperature it was cooled down immediately to a final temperature of 30ºC at cooling rate of 30ºC/min too. For the second treatment (B) the equipment was also programmed to reach a final temperature of 90 ºC with a heating rate of 30 ºC/min, but holding the temperature for 15 seconds, and immediately cooled down to a final temperature of 30ºC at 30ºC/min too. 10 samples of each vegetable soups were taken in sterile Falcon tubes during the process. The samples were kept frozen until analysed. These heat treatments have demonstrated to be effective for food safety and microbiological inactivation (Gironés-Vilaplana et al. 2016).

2.4. pH, and Total Soluble Solids (SS)

pH, and Total Soluble Solids (SS) were evaluated as quality indexes following the method reported by Mena et al. (2011). Results were expressed in ºBrix in TSS.

2.5. Colour parameters

Solutions were measured in glass cells of 10-mm path length (CT-A21) at 520 nm using a Minolta CM-508i® tristimulus colour spectrophotometer (Osaka, Japan) coupled with a CM-A760 transmittance adapter. CIEL∗, a∗ and b∗ values were calculated using illuminant D65 and a 10◦ observer, according to the CIEL*a*b* 76 Convention (McLaren 1980). Data were recorded and processed on a Minolta Software ChromaControl S, PC-based colorimetric data system. Hue angle (H) was calculated from tan−1 (b*/a*) and Chroma (C*) from from (a2 + b2)^1/2. All measurements were done in triplicate, and the mean values reported in each case.

2.6. Analysis of phenolic compounds by RP-HPLC-DAD

For the quantification, all samples were also centrifuged for 5 min at 9500 g. Each supernatant was filtered through a 0.45-μm PVDF filter (Millex HV13, Millipore, Bedford, MA, USA) before injection into the HPLC system, an Agilent 1260 Infinity equipped with a binary pump (model G 1312 B), a degasser (model G 1379 B), an autosampler (model G 1313-44510), and a diode array detector, DAD (model G 4212 B) that is controlled by the Agilent software B. 02. 02. Water/formic acid (99:1, v/v) and acetonitrile were used as the mobile phases A and B, respectively, with a flow rate of 0.8 ml/min. The linear gradient started with 99% A, 0 min.; 83% A, 15 min.; 75% A, 22 min.; 65% A, 30 min.; 50% A, 35 min.; 50% A, 45 min.; and 99% A, 50 min, which was maintained to 55 min. The injection volume was 20 µL. Taking into account that the major phenolic compounds found in tomato, carrot, and other vegetables present in this soups are hydroxycinnamic acid derivatives and flavonol glycosides (Ma et al. 2013; Sánchez-Rodríguez et al. 2011), chromatograms were recorded at 320, and 360 nm. Flavonols were quantified as quercetin 3-O-rutinoside at 360nm, and cinnamic acids as 5-O-caffeoylquinic acid at 320 nm.

2.7. Antioxidant capacity

The free radical scavenging activities were determined using the DPPH•, ABTS˙+, and FRAP (ferric reducing antioxidant power) methods adapted to a microscale, according to Mena et al. (Mena et al. 2011). The antioxidant activity was evaluated by measuring the variation in absorbance at 515 nm after 50 min of reaction with the radical (for DPPH•), at 414 nm after 50 min (ABTS˙+), and at 593 nm after 40 min for FRAP. The assays were performed using 96-well micro plates (Nunc, Roskilde, Denmark) and an InfiniteÒ M200 micro plate reader (Tecan, Grödig, Austria). All the reactions were started by adding 2 μL of the corresponding diluted sample to the well containing the stock solution (250 μL). The final volume of the assay was 252 μL. The antioxidant activity was also determined using the ORAC-FL assay, according to Ou et al. (2001). The results were expressed as mM Trolox.

2.8. Statistical analysis

The data are presented are mean values (n=3) ± standard deviation. All the data were subjected to analysis of variance (ANOVA) and a Multiple Range Test (Tukey’s test), using IBM SPSS statistics 21 software (SPSS Inc., Chicago, IL, USA). Pearson’s correlation analysis was performed to corroborate the relationships between selected parameters.

3.1. Quality parameters

The quality parameters showed slight differences between products and between heat treatments (Table 1).

|

Table 1. pH and SS of food products subjected to different heat treatments |

||

|

|

pH |

SS |

|

COS: Carrot. orange and coriander cold soup |

|

|

|

Tank |

4.34 ± 0.04 b |

6.00 ± 0.00 a |

|

90ºC treatment (1) |

4.28 ± 0.01 ab |

6.00 ± 0.00 a |

|

90ºC/15seg. treatment (2) |

4.17 ± 0.01 a |

6.00 ± 0.00 a |

|

Commercial |

4.15 ± 0.05 a |

6.53 ± 0.12 b |

|

LSD, p < 0.05 |

0.034 |

0.047 |

|

GAZ: Gazpacho |

|

|

|

Tank |

3.96 ± 0.00 b |

6.53 ± 0.12 ab |

|

90ºC treatment (1) |

3.98 ± 0.01 b |

6.40 ± 0.00 a |

|

90ºC/15seg. treatment (2) |

3.96 ± 0.01 b |

6.40 ± 0.00 a |

|

Commercial |

3.86 ± 0.00 a |

6.67 ± 0.12 b |

|

LSD, p < 0.05 |

0.005 |

0.067 |

|

TMS: Tomato. mint and basil cold soup |

|

|

|

Tank |

3.85 ± 0.00 b |

5.60 ± 0.20 a |

|

90ºC treatment (1) |

3.84 ± 0.01 b |

6.27 ± 0.23 b |

|

90ºC/15seg. treatment (2) |

3.85 ± 0.01 b |

6.00 ± 0.00 ab |

|

Commercial |

3.81 ± 0.01 a |

5.93 ± 0.12 ab |

|

LSD, p < 0.05 |

0.006 |

0.133 |

|

n=3 ± SD. Different letters means significantly different at P < 0.05 according to Tukey HSD Multiple Range Test.

|

||

In COS, pH values were affected by thermal treatment, the sample subjected to 90° C/15 s. and the commercial one were significantly more acid (pH 4.17 ± 0.01 and 4.15 ± 0.05 respectively) than tank sample (pH 4.34 ± 0.04). Total Soluble Solids (SS) content was significantly higher in commercial sample (6.53 ± 0.12 °Brix) than in the rest of COS products, whose content was 6.00 ± 0.00 °Brix.

In GAZ, both treatments applied did not affect the pH of the final product. However, commercial sample presented slight differences, with pH values of 3.86± 0.00 while tank sample had a pH of 3.96± 0.00. SS content was affected by both treatments showing commercial GAZ higher content (6.67± 0.12 °Brix).

As in GAZ, TMS only displayed pH variation in commercial sample, which with a pH value of 3.81 ± 0.01 was the most acid sample among all products studied. SS content was significantly increased in the sample treated at 90°C (6.27 ± 0.23 ° Brix) with respect to tank sample (5.60 ± 0.20 ° Brix). The rest of TMS products were not significantly different from the tank sample.

Although there have been slight changes in pH and SS, these were not significant, and did not affect to the final product characteristics. These results are in agreement with previous ones (Odriozola-Serrano et al. 2008), who also evaluated the effect of heat treatment (90°C for 30 or 60 s.) in tomato juices and did not reported significant changes in pH and SS, concluding that the no significant changes are indicative of a correct thermal treatments.

3.2. Colour alterations

Colour is a crucial organoleptic characteristic that triggers the first response of the consumer in contact with the product (Gironés-Vilaplana et al. 2013b). In this sense, tristimulus colorimetry is considered as the best method to evaluate this visible colour (Khandare et al. 2011), with the use of CIEL*a*b* parameters. Heat treatments displayed changes in the CIEL*a*b* values of all the food products tested (Table 2), but not in the same way.

In COS (usually orange), the CIEL* value of the commercial sample (56.53) was slightly higher than the tank sample (52.93 ± 0.02), indicative of a clearance in the soup after heat treatment (Table 2). CIEa* (indicator of red coloration) value of the tank sample showed an appreciable decrease after the application of heat treatment, reaching the lowest value in the commercial sample (4.23). On the contrary, the CIEb* (responsible for yellow/bluish colorations) parameter reported a significant increase, presenting the commercial sample the highest value (53.64), compared with the lowest value found in the tank sample (40.60). This last effect demonstrated that thermal treatment caused an increase of yellowness of the commercial product, probably due to changes in carotene pigments during heating, as previously reported (Quitão-Teixeira et al. 2009). The same trend was observed in Chroma (C) and Hue angle (H) values, with an increase of both, from the tank product to commercial sample, rendering more yellow colour, but, it must be said that inappreciable for the human eye.

Regarding GAZ samples, the lowest value of CIEL* (37.91) was reported in the sample treated with 90°C maintained during 15s., meanwhile the other heat treatment (reached to 90°C and instant cooling) did not showed differences in CIE L* parameter with respect to tank sample (Table 2). The highest value was presented by commercial sample (40.08 ± 0.22), although was similar in the 4 samples of gazpacho. Commercial GAZ was also the sample with highest CIEa* (12.01), CIEb* (20.33) and Chroma (23.62) values, resulting in an increase of red and yellow coloration of the food product (which is usually red), although this change was, also, imperceptible to the human eye. Regarding the Hue angle parameter, commercial sample and treated at 90°C exhibited the lowest (59.44) and the highest (64.80 ± 0.04) values among all the GAZ samples, respectively. Although significant differences were reported (p<0.05), these were not large, indicative of soft heatings.

In TMS, with red coloration, an increase was noted in CIEL* value due to the heat treatment (Table 2), obtaining the highest value (41.26) in the commercial product. On the other hand, CIEa* parameter was similar in all samples analysed of this kind of soup, showing only minimal changes. The CIEb* and Chroma values of commercial samples were higher when compared to rest of TMS samples, resulting in an increase of the yellow coloration in the commercial sample due to heat treatment, as observed in the other samples, since CIEb* is associated to yellowness. The commercial TMS was the one that also presented the highest Hue value (74.54), rendering a more yellow coloration, but too difficult to appreciate for the consumer.

CIEL*a*b* parameters of COS samples were affected by thermal treatments, probably due to carotene changes during heating, as previously demonstrated (Quitão-Teixeira et al. 2009), although these changes were not enough to be appreciated by the human eye. For those products whose main ingredient was tomato (GAZ and TMS), CIEL*a*b* parameters of commercial sample were the highest among all the samples (tank and treated samples). As in our case, Patras et al. (Patras et al. 2009a) found that heat-processed tomato purees had significantly higher Chroma values than the untreated samples, concluding that this fruit can be affected by heat treatment. However, these changes were not so significant in any of the three studied products in this work, remaining stable CIEL*a*b* parameters during thermal treatments, and being the treatment that reached to 90°C and instant cooling the least changes in the CIEL*a*b* values showed.

3.3. Changes in Phenolic compounds

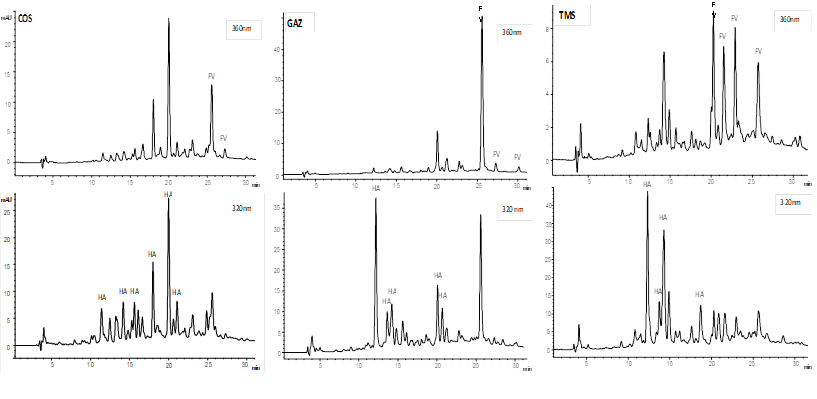

Considering that the major phenolics found in tomato an carrot vegetables (predominant in cold soups studied in this work) are hydroxycinnamic acid derivatives and flavonol derivatives (Ma et al. 2013; Sánchez-Rodríguez et al. 2011), these compounds present in the different products were detected and quantified by the characteristic spectrum at 360 nm (flavonols), and at 320 nm (hydroxycinnamic acids) (Figure 1). The effects of heat treatments on phenolic compounds were also determined from the concentration in the different samples.

Fig.1 Chromatograms of cold soups (COS, GAZ and TMS) at 360 nm (flavonols) and 320 nm (hydroxycinnamic acids). FV: Peaks quantified as flavonols by spectrum. HA: Peaks quantified as hydroxycinnamic acids by spectrum.

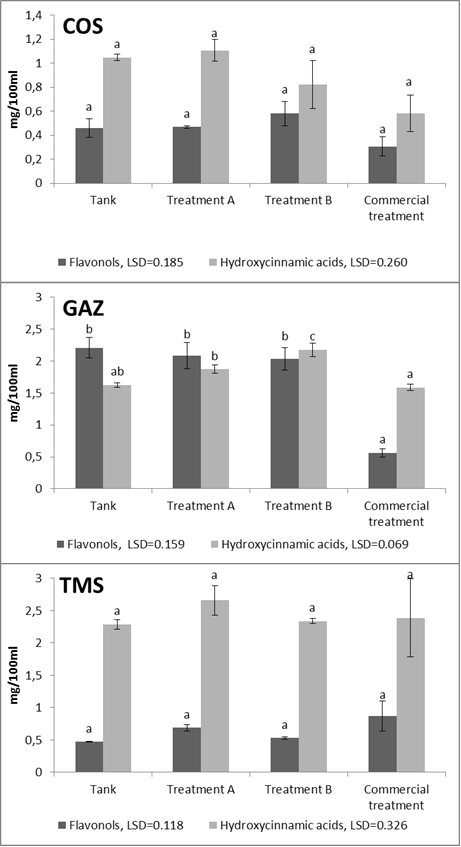

Main phenolic compounds found in carrots are chlorogenic acid (5-caffeoylquinic acid) and p-hydroxybenzoic acid with other cinnamic acid derivatives (Gonçalves et al. 2010). However it can be variations caused by the diversity of varieties of carrots and other processing factors (Ma et al. 2013). In COS, taking the example of the tank sample, the flavonol content was 0.46 ± 0.08 mg/100 ml, being hydroxycinnamic acids quantity more than double (1.11 ± 0.10 mg/100 ml). All the analysed phenolic compounds did not showed significant differences between untreated and treated samples (Figure 2), same that published by Patras et al. (2009a) in carrot purees, but contrary to reported by Ma et al. (2013), which demonstrated that pasteurisation reduced polyphenols stability in carrot juice.

Fig.2 Mean values (N=3 ± SD) of the phenolic compounds present in COS, GAZ and TMS. Different letters means significantly different at P < 0.05 according to Tukey HSD Multiple Range Test.

Regarding the content of the different phenolic compounds in GAZ (Figure 2), flavonols content was reduced as a result of the thermal treatment applied to commercial sample, which featured a flavonol content of 0.56 ± 0.06 mg/100 ml. Therefore, tank sample presented an almost four times higher quantities (2.2 ± 0.16 mg/100 ml), and this content was not affected by both treatments of 90°C and 90°C/15s., demonstrating a high effectivity of treatments used in this study. Hydroxycinnamic acid content was higher in 90°C/15s. treatment, with an amounts of 2.18 ± 0.11 mg/100 ml, while in the tank sample was 1.63 ± 0.04 mg/100 ml. Commercial sample showed again the lowest content of total hydroxycinnamic acids derivatives (1.59 ± 0.05 mg/100 ml), although without significant differences with tank sample. These results indicate that the cold soups could suffer more stress in commercial treatment, probably by higher times at elevated temperature.

Phenolic compounds of TMS soup remained unaffected as a result of the different heat treatments applied (Figure 2). With respect to tank sample, flavonols derivatives displayed the smallest amounts: 0.47 ± 0.00 mg/100 ml, quantifying approximately five times higher quantities of hydroxycinnamic acid derivatives (2.28 ± 0.07 mg/100 ml). The amounts of flavonols and hydroxycinnamic acids of TMS were smaller and higher respectively than quantified for GAZ, probably due by the different vegetable ingredients employed, since lemon juice (third main ingredient of TMS) is very rich in chlorogenic and neochlorogenic acids (Girones-Vilaplana et al. 2014) and pepper (second main ingredient of GAZ) is rich in flavonol O-glycosides (Wahyuni et al. 2014). However, no flavanones (characteristic lemon flavonoids) were found. Regarding to the effect of thermal treatments in products with tomato as main ingredient (GAZ and TMS), only commercial treatment in GAZ affect to phenolic content, the rest of heat treatment did not affect the final product in terms of phenolic quantity, as previously reported for tomato purees (Patras et al. 2009a). Moreover, Odriozola-Serrano et al. (Odriozola-Serrano et al. 2008) did not found significant differences in total phenolic content between tomato juices heat-treated and untreated too, as reported in this study. In addition, they found that chlorogenic acid was the main hydroxycinnamic acid derivative in tomato juice, in treated and untreated samples.

3.4. Antioxidant activity

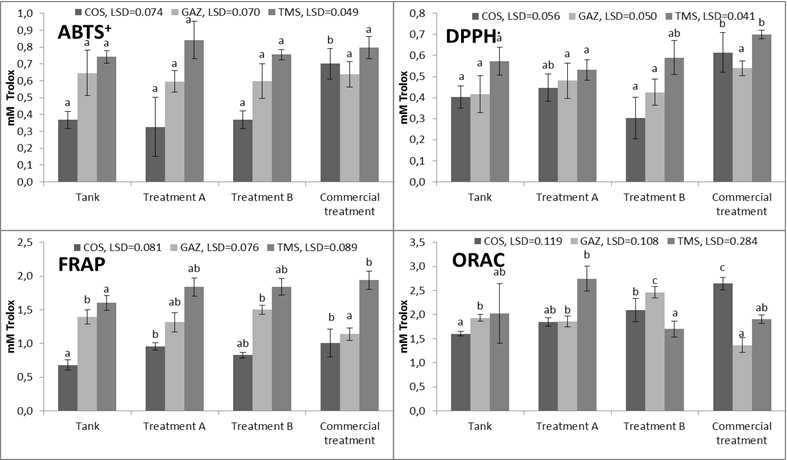

The antioxidant capacity of cold soups was evaluated against different reactive species: ABTS+, DPPH·, FRAP, and ORACFL, in order to compare the diverse reactivity of the samples in the different assays. The DPPH· and ABTS+ are non-biological radicals extensively used to test the antioxidant capacity of plant samples. Other widespread methods for the evaluation of the antioxidant capacity of vegetal samples are FRAP, based on the reduction of Fe; and ORAC, based on the ability of peroxyl radical scavenging. Each antioxidant in a complex mixture (food matrix) has a different activity pattern for each method, resulting in different data for each assay. Therefore, to be sure that a sample possesses a significantly-high antioxidant capacity, and to provide a more complete evaluation of the antioxidant capacity of vegetable food products, several assays should be used (Gironés-Vilaplana et al. 2013b).

With regards to ABTS+ (Figure 3), COS increased its value (0.70 ± 0.09 mM Trolox) as a result of the treatment applied to commercial sample. The other treatments studied did not showed any difference with respect tank sample, whose value was 0.37 ± 0.05 mM Trolox. Likewise, the antioxidant capacity of GAZ and TMS were not affected by heat treatments studied because they had similar values to the tank samples (0.65 ± 0.14 mM Trolox and 0.74 ± 0.04 mM Trolox, respectively). ABTS+ antioxidant activity was significant correlated to total hydroxycinnamic content (r=0,713**, p<0,005). However, tomato and carrot juices have demonstrated to be not so good scavenger of ABTS+ radical, probably because of their main bioactive compounds react better with other radicals (Wootton-Beard et al. 2011).

Fig.3 Antioxidant activity (N=3 ± SD) of COS, GAZ and TMS measured by ABTS+, DPPH·, FRAP, and ORACFL methods. Different letters means significantly different at P < 0.05 according to Tukey HSD Multiple Range Test.

Concerning the FRAP method (Figure 3), COS values was increased in treated sample at 90°C (0.96 ± 0.06 mM Trolox) and commercial sample (1.00 ± 0.21 mM Trolox) with respect to the tank sample (0.68 ± 0.08 mM Trolox). In GAZ, commercial sample was affected, since its value was reduced to 1.14 ± 0.10 mM Trolox with respect to the tank sample (1.40 ± 0.11 mM Trolox), which presented similar values than samples treated at 90°C and 90°C/15s. Meanwhile, the commercial sample of TMS increased its value (1.94 ± 0.14 mM Trolox) with respect to the sample tank (1.6 ± 0.11 mM Trolox). Moreover, all these FRAP values was strongly correlated with total hydroxycinnamic acids (r=0.921**, p=0), which was indicative of the influence of these phenolics on the antioxidant activity of the samples. These FRAP values were similar than previously reported for different vegetable juices, including tomato and carrot juices (Wootton-Beard et al. 2011).

In the ORACFL method (Figure 3), tank sample of COS displayed lower values of antioxidant capacity than treated samples: 1.60 ± 0.05 mM Trolox for tank sample, 2.09 ± 0.24 mM Trolox for sample treated at 90°C/15s, and 2, 64 ± 0.13 mM Trolox for commercial sample. In GAZ, commercial sample showed the lowest value (1.37 ± 0.15 mM Trolox) with notable differences with respect tank sample (1.93 ± 0.07 mM Trolox). The ORACFL value obtained in the sample treated at 90°C/15s. highlighted among all GAZ samples (2.46 ± 0.12 mM Trolox). Regarding TMS, tank and commercial samples did not differ (2.03 ± 0.62 mM Trolox and 1.90 ± 0.09 mM Trolox, respectively), although the sample treated at 90°C reported significantly higher value (2.75 ± 0.26 mM Trolox). Previous research has evaluated the ORACFL activity of carrot and tomato fruits (Ou et al. 2001; Wu et al. 2004), reporting good antioxidant activity, as in our study.

The different antioxidant capacity methods employed revealed that COS retained its antioxidant capacity after thermal processing, reaching to increase in some cases the commercial sample. Ma et al. (2013) reported the same for carrot juice, so this cold soup with thermal treatment applied can serve as a possible source of natural dietary antioxidants to human nutrition and health.

On the other hand, GAZ was not greatly influenced by the heat treatment, although in some cases the antioxidant capacity decreased in commercial samples. TMS was not greatly affected by heat treatments in terms of their antioxidant capacity, leading to increase in some cases in commercial samples, as happened to COS. It has been demonstrated that pasteurization did not have a remarkable effect on antioxidant activity of tomato puree, even can increase the extractability of the folates and maintaining the carotenoid and phenolic content, compounds responsible for the antioxidant activity (Pérez-Conesa et al. 2009).

Overall, TMS was the sample with the highest antioxidant capacity, followed by GAZ, and showing COS the lowest antioxidant capacity, probably due to the lowest quantities of phenolic compounds, present in COS samples, with demonstrated strong antioxidant activity (Mitjavila and Moreno 2012). Nevertheless, the broad range of activities of the cold soups indicates that multiple mechanisms may be responsible for the antioxidant activity, linked to phenolic compounds (Gironés-Vilaplana et al. 2012).

|

Table 2. CIEL*a*b* colour parameters of the vegetable food product with the different heat treatments applied. |

|||||

|

|

|

||||

|

|

COS: Carrot. orange and coriander cold soup |

|

|||

|

|

Tank |

90ºC treatment (1) |

90ºC/15seg. treatment (2) |

Commercial |

LSD, p < 0.05 |

|

L* |

52.93 ± 0.02 a |

53.43 ± 0.06 b |

52.94 ± 0.02 a |

56.53 ± 0.00 c |

0.030 |

|

a* |

9.62 ± 0.01 d |

8.26 ± 0.04 c |

7.88 ± 0.02 b |

4.23 ± 0.02 a |

0.029 |

|

b* |

40.60 ± 0.09 a |

43.77 ± 0.14 b |

47.40 ± 0.11 c |

53.64 ± 0.10 d |

0.111 |

|

Chroma |

41.72 ± 0.09 a |

44.54 ± 0.13 b |

48.05 ± 0.10 c |

53.81 ± 0.10 d |

0.108 |

|

Hue |

76.67 ± 0.05 a |

79.31 ± 0.09 b |

80.56 ± 0.05 c |

85.49 ± 0.03 d |

0.057 |

|

|

|

||||

|

|

GAZ: Gazpacho |

|

|||

|

|

Tank |

90ºC treatment (1) |

90ºC/15seg. treatment (2) |

Commercial |

LSD, p < 0.05 |

|

L* |

39.06 ± 0.02 b |

38.61 ± 0.02 b |

37.91 ± 0.03 a |

40.08 ± 0.22 c |

0.112 |

|

a* |

7.16 ± 0.03 b |

6.43 ± 0.00 a |

8.44 ± 0.00 c |

12.01 ± 0.07 d |

0.038 |

|

b* |

12.78 ± 0.01 a |

13.66 ± 0.02 b |

16.07 ± 0.01 c |

20.33 ± 0.27 d |

0.138 |

|

Chroma |

14.65 ± 0.01 a |

15.09 ± 0.02 a |

18.15 ± 0.01 b |

23.62 ± 0.27 c |

0.138 |

|

Hue |

60.73 ± 0.11 b |

64.80 ± 0.04 d |

62.29 ± 0.01 c |

59.44 ± 0.19 a |

0.112 |

|

|

|

||||

|

|

TMS: Tomato. mint and basil cold soup |

|

|||

|

|

Tank |

90ºC treatment (1) |

90ºC/15seg. treatment (2) |

Commercial |

LSD, p < 0.05 |

|

L* |

36.27 ± 0.03 a |

36.55 ± 0.01 b |

37.97 ± 0.00 c |

41.26 ± 0.04 d |

0.026 |

|

a* |

4.80 ± 0.02 b |

4.63 ± 0.01 a |

4.87 ± 0.02 c |

4.88 ± 0.01 c |

0.018 |

|

b* |

10.90 ± 0.05 a |

12.17 ± 0.01 b |

12.08 ± 0.02 b |

17.65 ± 0.05 c |

0.034 |

|

Chroma |

11.91 ± 0.03 a |

13.03 ± 0.01 b |

13.03 ± 0.01 b |

18.31 ± 0.05 c |

0.029 |

|

Hue |

66.26 ± 0.18 a |

69.17 ± 0.07 c |

68.03 ± 0.11 b |

74.54 ± 0.00 d |

0.110 |

|

n=3 ± SD. Different letters means significantly different at P < 0.05 according to Tukey HSD Multiple Range Test. |

|||||

The heat treatments applied to the products studied not affect significantly the pH and SS, being found small differences between tank and commercial samples. The colour of the analysed products were affected by the different heat treatments applied, rendering, in general, the commercial treatment more significant changes in CIEL*, CIEb*, and Chroma, giving a little increase of yellow coloration, inappreciable for human eye. Regarding phenolic compounds, these did not suffer any variation in all cold soups with the treatments employed, being only reduced in commercial treatment, indicating that this samples could suffer more stress. COS and TMS also maintained the antioxidant capacity after different thermal processes, being GAZ not severely affected, even though in some antioxidant methods decreased in commercial samples. Although it has been determined that some heat treatments slightly affected certain parameters studied in some of the cold soups evaluated, these variations were not significant, so the applied treatments can be very effective to preserve the shelf life of these products, maintaining many of its crucial properties for the food industry, and being both heat treatments better than commercial heating in terms of preservation of the parameters presented.

The authors express their gratitude to the Seneca Foundation project: Aids for Groups and Units of Excellence in Murcia Region (Ref 19900/GERM/15), and to the Spanish Ministry of Economy and Competitiveness of the Spanish Government and European Regional Development Fund (ERDF) for the Research Project AGL2013-48993-C2-1-R.